BS-215G Horizontal Band Saw

Cutting Capacity :

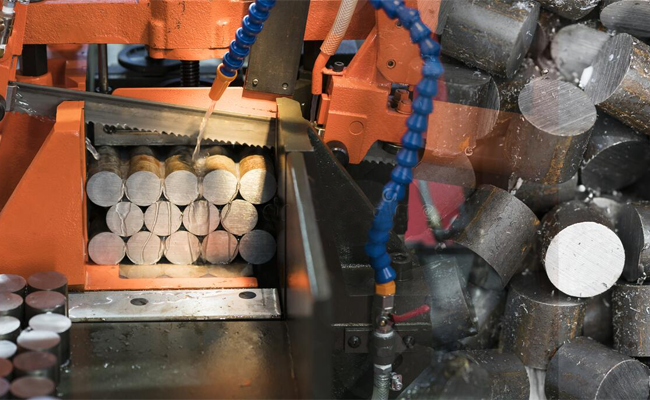

In modern industrial production, the application of fully automatic circular saws has gradually become the mainstream. Its high-efficiency and precise cutting capabilities have enabled many companies to significantly improve production efficiency. However, how to load fully automatic circular saws is also a crucial process. The loading process directly affects the cutting accuracy, production continuity and equipment life. Therefore, mastering the correct method of loading fully automatic circular saws plays a vital role in optimizing production processes and improving product quality.

How to load fully automatic circular saws

The loading methods of fully automatic circular saws are usually divided into two categories: manual loading and automatic loading. Traditional manual loading methods often rely on workers’ experience and operating skills, but this method is not only labor-intensive, but also prone to errors, affecting production efficiency. With the advancement of technology, fully automatic loading systems have emerged. It organically combines material delivery with machine cutting operations, realizes automated assembly line operations, greatly reduces manpower input, and ensures loading accuracy and cutting quality.

For the loading process of the fully automatic circular saw machine, first of all, it is necessary to ensure that the specifications of the raw materials used meet the requirements of the machine. The length, thickness, width and other parameters of the material must be within the range set by the machine, otherwise it may cause jamming, offset or even equipment damage. Therefore, when purchasing and preparing materials, enterprises need to strictly control the material specifications to ensure that they match the parameters of the fully automatic circular saw machine.

Next, in actual operation, enterprises usually choose to equip automatic loading racks or conveyor belts, which can automatically transport raw materials to the sawing machine. The loading system of the fully automatic circular saw machine can automatically identify the position of the material and accurately locate it through sensors or control programs. In this process, the operator only needs to make simple settings, and the machine will complete the entire loading, positioning and cutting process according to the set parameters. This fully automated loading method not only improves production efficiency, but also reduces material waste and production costs.

The loading methods of fully automatic circular saw machines of different brands and models are slightly different. Some equipment is equipped with a more intelligent feeding platform, which can automatically adjust the feeding speed and angle according to the shape, weight and length of the material to ensure that each piece of material is in the best position when entering the sawing machine. For larger or heavier materials, some fully automatic circular saws are equipped with hydraulic lifting platforms, which can effectively reduce the pressure of manual feeding and improve safety.

In the daily use of fully automatic circular saws, it is also important to regularly check and maintain the feeding system. Due to the long-term operation of the automatic feeding system, the transmission parts, sensors and conveying devices may be worn or blocked. Therefore, enterprises should regularly inspect and maintain these parts, clean up the debris on the conveyor belt in time, and ensure the smooth operation of the feeding system. In addition, lubricating the moving parts and checking the sensitivity and accuracy of the sensors are also one of the key measures to ensure the high-efficiency operation of the feeding system.

In actual production, enterprises can also flexibly adjust the feeding method of fully automatic circular saws according to their own needs. For example, for enterprises engaged in mass production, a fully automatic in-line feeding system can be used, that is, multiple feeding devices are connected to the fully automatic circular saw machine to achieve synchronous feeding and cutting of multiple stations, further improving production efficiency. For enterprises engaged in small-batch customized production, manual assisted feeding or semi-automatic feeding may be more flexible and economical.

In short, the feeding process of the fully automatic circular saw machine occupies an important position in the entire production process. Choosing a suitable feeding system and performing reasonable maintenance and adjustment on it can significantly improve the production efficiency of the enterprise and reduce unnecessary material waste and labor costs. Whether it is manual feeding or fully automatic feeding, enterprises should flexibly formulate feeding strategies according to their own production scale, equipment performance and material characteristics to ensure that the fully automatic circular saw machine can operate efficiently in a better state.

Cutting Capacity :

Cutting Capacity :