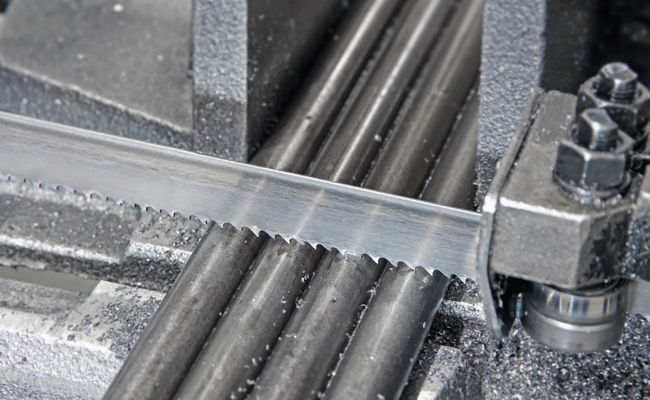

GZ4230 Fully Automatic Band Saw Machine

Cutting Capacity :

Cutting stainless steel requires precision, the right tools, and specific knowledge. Selecting the correct band saw blade is critical for achieving clean cuts, maximizing blade life, and ensuring operational efficiency. This guide breaks down everything you need to know to choose and use the best band saw blade for your stainless steel projects.

Stainless steel is known for its strength, durability, and corrosion resistance. These properties, primarily due to the addition of chromium and nickel, also make it difficult to cut. The material tends to work-harden during cutting, generating significant heat and causing premature blade wear if the wrong blade or technique is used.

Selecting the ideal blade involves considering four main elements. Getting this combination right is the secret to successful cutting.

The blade’s material must be harder than the stainless steel being cut.

Bi-Metal (Most Recommended): The best overall choice. They feature a flexible high-speed steel (HSS) tooth edge welded to a durable alloy steel back. This combination provides the necessary hardness to cut through stainless steel while resisting heat and fatigue.

Carbide-Tipped: Used for the most demanding and production-oriented applications. They are extremely hard and wear-resistant, ideal for cutting abrasive stainless steels or for very high-volume work. They are also the most expensive option.

Choosing the correct TPI is vital for a smooth cut and long blade life. A general rule is to ensure a minimum of 2-3 teeth are in contact with the material at all times.

| Material Size & Type | Recommended TPI | Why This Works |

|---|---|---|

| Thin-walled tubing & small profiles | 18-24 TPI | A finer pitch prevents teeth from snagging and breaking on thin sections. |

| General purpose cutting (most common) | 14-18 TPI | A versatile range that provides a good balance of cut speed and finish on a wide array of bar stock and pipe. |

| Large solid bars (>4″ thick) | 10-14 TPI | A coarser pitch provides larger chip pockets to clear material efficiently, reducing heat buildup. |

The shape and arrangement of the teeth affect cutting speed, finish, and chip removal.

Variable Pitch (VP): This is highly recommended for stainless steel. The varying tooth spacing disrupts the harmonic vibration during cutting, resulting in a smoother cut and significantly reduced noise. It also helps in breaking chips effectively.

Raker Set: The most common set for cutting metal. Groups of teeth alternate left and right with a straight (raker) tooth in between. This is ideal for cutting solid sections of stainless steel as it provides good chip clearance and a clean cut.

The width of the blade should be chosen based on the saw’s capabilities and the cut’s geometry.

Narrow Blades (1/2″ or less): Better for cutting curves or contours.

Wider Blades (3/4″ and above): Provide more stability and are used for straight cuts on larger band saw machines. They are less likely to break under heavy feed pressure.

Using the right blade is only half the battle. Proper technique is equally important.

Use the Correct Cutting Speed (SFPM): Stainless steel must be cut at lower surface feet per minute (SFPM) than mild steel.

Recommendation: Start between 80 – 120 SFPM and adjust based on the specific grade of stainless. Refer to your blade manufacturer’s chart.

Apply Consistent, Moderate Feed Pressure: Let the blade do the work. Forcing the blade generates excessive heat, leading to work-hardening and rapid tooth wear. A steady, controlled feed rate is key.

Use Adequate Coolant or Lubricant: This is non-negotiable for stainless steel. Coolant serves two crucial purposes:

Dissipates heat from the cutting zone.

Lubricates the blade, reducing friction and improving finish.

Use a quality cutting fluid designed for stainless steel operations.

Ensure Proper Machine Setup: A well-maintained saw is essential. Check blade guides, bearings, and band tension regularly. A misaligned or poorly tuned saw will ruin even the best blade.

Before you make a cut, run through this list:

Blade Type: I am using a bi-metal blade.

TPI: I have selected the correct TPI for my material size (e.g., 14-18 TPI for general use).

Tooth Geometry: My blade has a variable pitch for a smoother cut.

Speed: My band saw speed is set low (~100 SFPM).

Lubrication: My coolant system is on and functioning.

Feed: I am applying steady, moderate pressure.

Cutting stainless steel doesn’t have to be a frustrating experience. By investing in a high-quality bi-metal band saw blade with the correct TPI and variable pitch, and by adhering to best practices involving low speed, steady feed pressure, and ample coolant, you can achieve precise, efficient, and cost-effective cuts every time. Remember, the right tool and the right technique are the perfect combination for mastering stainless steel.

Cutting Capacity :

Cutting Capacity :