BS-916B Metal Cutting Bandsaw

Cutting Capacity :

As one of the indispensable equipment in modern industrial production, CNC high-speed circular saw machine plays an important role in various metal processing with its high-precision cutting ability. Today, let’s take a detailed look at the various components of CNC high-speed circular saw machine, and show you how a circular saw machine can be produced through precise engineering design and CNC technology.

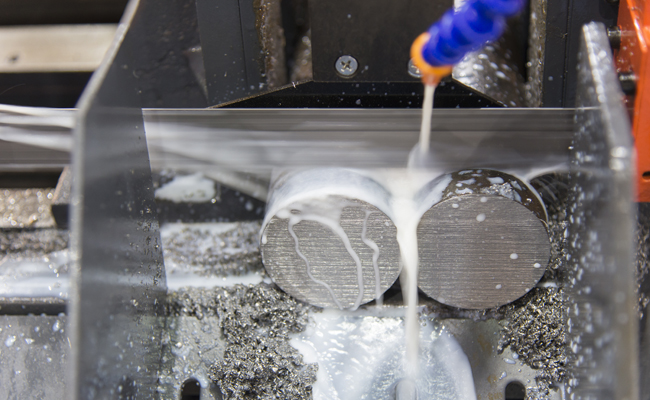

The band saw machine cutting the steel rod with the coolant

The core components of CNC high-speed circular saw machine include main structure, saw blade system, feeding system, control system and safety protection device. These components cooperate with each other to complete the complex process from material positioning to cutting, providing reliable guarantee for the processing of various metal materials.

First, the main structure of CNC high-speed circular saw machine carries the mechanical parts of the entire equipment, including machine tool base, bracket, guide rail and cutting table. The stability and precision of the main structure directly affect the cutting accuracy and stability during sawing. The main structure of modern circular saw machine is usually made of high-strength alloy cast iron or steel, and is precision machined and heat treated to ensure stability and vibration resistance during high-speed operation.

Second, the saw blade system is a key component of the CNC high-speed circular saw machine, responsible for cutting the workpiece. The saw blade system is usually composed of a driving shaft, a saw blade, a blade holder, a spindle drive device, etc. The selection and installation of the saw blade is very critical. Different saw blade materials and blade numbers are suitable for different materials and cutting requirements. For example, saw blades made of high-speed steel, carbide and other materials can meet the cutting requirements of metals of different hardness and thickness.

Third, the feeding system is responsible for feeding the workpiece into the saw blade for cutting according to the preset length and angle. The feeding system is generally composed of a feeding fixture, a feeding guide rail, a feeding motor and a controller, and the precise positioning and movement of the workpiece are achieved through a precise electronic control system. The CNC technology can enable the feeding system to achieve high-speed and high-precision workpiece positioning and feeding, improving production efficiency and cutting accuracy.

The control system is the brain of the CNC high-speed circular saw machine, integrating functions such as motion control, position feedback, and cutting parameter adjustment. The control system of modern CNC circular saw machines usually adopts PLC (programmable logic controller) or CNC (computer numerical control) system, which is operated and monitored through touch screen or computer interface. Operators can achieve the cutting requirements of different workpieces by setting cutting parameters, adjusting cutting angles and lengths, etc., which greatly improves the convenience of operation and the flexibility of production.

Fourth, the safety protection device of CNC high-speed circular saw machine is an important part of ensuring the safety of operators. Since there are certain safety hazards when the circular saw machine is running at high speed, the safety protection device includes saw blade cover, safety door, emergency stop button, etc., to ensure that the operator will not be accidentally injured during the operation, and can respond to emergencies in time to ensure production safety.

In summary, CNC high-speed circular saw machine has become an indispensable and important equipment in modern industrial production with its precise mechanical structure, CNC technology and safety protection device. Cutting ability not only improves production efficiency, but also injects new impetus into the development of metal processing industry. With the continuous advancement of science and technology, CNC high-speed circular saw machine still has broad development space in improving cutting accuracy and expanding application scope. I hope that through this article, you can have a deeper understanding of the composition and working principle of the CNC high-speed circular saw machine, and provide strong technical support and reference for your production activities.

Cutting Capacity :

Cutting Capacity :