BS-1018TH Metal Cutting Bandsaw

Cutting Capacity :

Band sawing machine is an efficient and precise cutting equipment, which is widely used in the field of metal processing. However, the cutting effect of band sawing machine depends largely on the selection of band saw blade. Different steel materials, hardness and shapes have different requirements for band saw blades. This article will introduce in detail how to choose the right band saw blade for band sawing machine to ensure efficient and precise cutting of steel.

1. Understand the characteristics of steel

Before choosing a band saw blade, you first need to clarify the characteristics of the steel to be cut, including material, hardness, size and shape. These factors directly affect the selection of band saw blades.

Material

There are many types of steel, such as carbon steel, alloy steel, stainless steel, etc. Steels of different materials have different hardness and toughness, so it is necessary to choose the appropriate saw blade material and tooth shape.

Hardness

High-hardness steel (such as hardened steel, tool steel) requires more wear-resistant saw blades, while soft steel (such as low carbon steel) can use general-purpose saw blades.

Size and shape

The thickness and shape of the steel will also affect the choice of saw blade. For example, thicker materials require wider saw blades to ensure stability, while workpieces with complex shapes require more flexible saw blades.

2. Choose the right saw blade material

The material of the band saw blade directly affects its cutting performance and life. The following are common band saw blade materials and their applicable scenarios:

Carbon steel saw blade

Features: low cost, suitable for cutting soft steel and non-ferrous metals (such as aluminum and copper).

Applicable scenarios: suitable for cutting ordinary low-carbon steel or occasions where cutting efficiency is not required.

Limitations: not suitable for cutting high-hardness steel, poor wear resistance.

Bimetallic saw blade

Features: composed of high-speed steel teeth and spring steel back, with both high hardness and toughness.

Applicable scenarios: suitable for cutting high-hardness steel (such as alloy steel, stainless steel), with a long service life and high cutting efficiency.

Advantages: high cost performance, widely used in industrial fields.

Carbide saw blade

Features: The teeth are made of carbide material, which has extremely high wear resistance and heat resistance.

Applicable scenarios: Suitable for cutting extremely hard or wear-resistant materials (such as stainless steel, titanium alloy, high-temperature alloy).

Advantages: Long life, suitable for high-precision cutting tasks.

Limitations: High price, suitable for high-demand industrial scenarios.

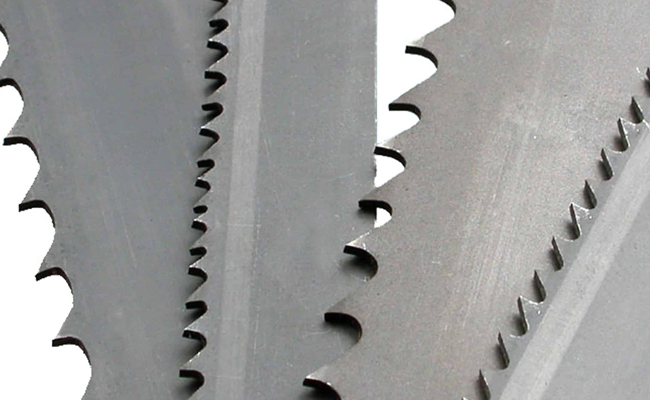

3. Determine the tooth shape and pitch of the saw blade

The tooth shape and pitch of the saw blade are important factors affecting the cutting effect. Different tooth shapes and pitches are suitable for different cutting tasks.

Standard teeth

Features: Uniform tooth shape, suitable for ordinary cutting tasks.

Applicable scenarios: Suitable for cutting ordinary steel or materials with uniform thickness.

Variable tooth shape

Features: Uneven tooth pitch can reduce vibration and noise.

Applicable scenarios: Suitable for cutting special-shaped materials or workpieces with uneven thickness.

Hook teeth

Features: Large pitch and strong chip removal ability.

Applicable scenarios: suitable for cutting soft steel or non-ferrous metal, with fast cutting speed.

Tooth pitch selection

Coarse tooth pitch: suitable for cutting thick materials, capable of fast chip removal.

Fine tooth pitch: suitable for cutting thin materials, capable of ensuring the flatness of the cutting surface.

4. Consider the width and thickness of the saw blade

The width and thickness of the saw blade directly affect the stability and accuracy of the cutting.

Width

Wide saw blade: suitable for cutting thick materials or straight cutting, with good stability.

Narrow saw blade: suitable for cutting complex shapes or curve cutting, with high flexibility.

Thickness

Thick saw blade: suitable for high-load cutting tasks, with high tensile strength.

Thin saw blade: suitable for fine cutting tasks, with better flexibility.

5. Other considerations

Cutting speed

Adjust the cutting speed of the band saw according to the hardness of the steel and the material of the saw blade. High-hardness steel requires a lower cutting speed, while soft steel can increase the speed appropriately.

Cooling and lubrication

During the cutting process, using appropriate coolants or lubricants can extend the life of the saw blade and improve the cutting quality.

Saw blade tension

Make sure the tension of the saw blade is moderate. Too loose will cause unstable cutting, and too tight may damage the saw blade.

Choosing the right band saw blade is the key to ensuring that the band saw machine can cut steel efficiently and accurately. By understanding the characteristics of steel, choosing the right saw blade material, tooth shape, tooth pitch, width and thickness, the cutting efficiency and quality can be significantly improved. In actual operation, it is also necessary to adjust the cutting speed and cooling and lubrication method according to the specific task to extend the life of the saw blade and optimize the cutting effect. I hope this article can provide valuable reference for your band saw machine operation!

Cutting Capacity :

Cutting Capacity :