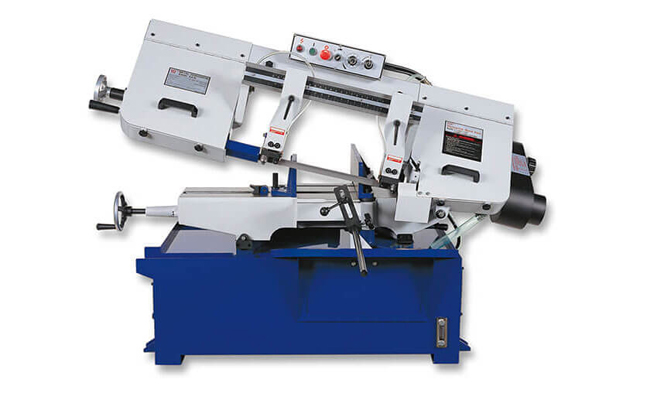

GZ4230 Fully Automatic Band Saw Machine

Cutting Capacity :

If you’re in metalworking, woodworking, or any industry that requires precise cutting, a horizontal bandsaw machine is a must-have tool. These machines deliver clean, accurate cuts with minimal waste, making them a favorite in workshops and factories.

we’ll break down everything you need to know about horizontal bandsaws—how they work, their benefits, key features to look for, and tips for getting the best performance.

What Is a Horizontal Bandsaw Machine?

A horizontal bandsaw is a power tool designed to cut metal, wood, or other materials using a continuous band blade. Unlike vertical bandsaws, which cut downward, horizontal bandsaws cut in a flat, forward motion. This design makes them ideal for cutting long bars, pipes, and bulky materials with precision.

Key Components of a Horizontal Bandsaw

Blade: A toothed metal band that rotates on wheels for cutting.

Vise: Holds the workpiece securely in place.

Hydraulic/Pneumatic feed: Controls the downward pressure for smooth cuts.

Coolant system: Reduces heat and prolongs blade life (common in metal-cutting models).

Cutting table: Supports the material during operation.

Why Choose a Horizontal Bandsaw?

1. Precision Cutting

Horizontal bandsaws provide straight, uniform cuts, which is crucial for fabrication and machining work.

2. Efficiency

They can handle large or multiple workpieces at once, reducing cutting time compared to manual saws.

3. Less Material Waste

The thin blade minimizes kerf loss, saving material and lowering costs.

4. Versatility

With the right blade, these machines cut various materials—steel, aluminum, plastic, and wood.

5. Safety

Since the workpiece remains stationary, operators have better control, reducing the risk of accidents.

Types of Horizontal Bandsaws

Manual Horizontal Bandsaws

Operator-controlled feed and cutting speed.

Best for small workshops or occasional use.

Semi-Automatic Bandsaws

Partial automation (e.g., hydraulic feed).

Balances cost and efficiency for mid-sized operations.

Fully Automatic Bandsaws

Programmable settings for high-volume cutting.

Ideal for industrial manufacturing.

How to Choose the Right Horizontal Bandsaw

1. Cutting Capacity

Check the maximum width and height of material the saw can handle.

2. Blade Speed & Material Compatibility

Lower speeds for hard metals.

Higher speeds for softer materials like wood or plastic.

3. Feed Control

Hydraulic feed for consistent pressure.

Gravity feed for simpler, budget-friendly models.

4. Build Quality

Look for heavy-duty frames and durable components for long-term use.

5. Additional Features

Coolant systems

Automatic shutoff

Variable speed control

Maintenance Tips for Longevity

Keep the blade sharp: Dull blades cause rough cuts and strain the motor.

Lubricate moving parts: Prevents wear and tear.

Check alignment: Misaligned blades lead to uneven cuts.

Clean regularly: Remove metal chips and debris to avoid clogging.

A horizontal bandsaw machine is a game-changer for any serious workshop. Whether you’re cutting metal stock, pipes, or lumber, this machine delivers efficiency, precision, and durability.

Before buying, assess your needs—consider material type, cutting volume, and automation level. With the right bandsaw, you’ll boost productivity and achieve cleaner cuts every time.

Looking for the best horizontal bandsaw? Compare models, read reviews, and invest in a machine that fits your workflow. Happy cutting!

Cutting Capacity :

Cutting Capacity :