BS-912GR Metal Cutting Bandsaw

Cutting Capacity :

Automatic high-speed circular saw machine is an industrial processing equipment that integrates automatic control and high-speed cutting technology. It is mainly used for precise cutting of hard materials such as metal, wood, and plastic. Its core design concept is to realize the full process automation from material loading, positioning, cutting to unloading through highly integrated mechanical structure and intelligent control system, which significantly improves production efficiency and processing accuracy.

In terms of technical architecture, automatic high-speed circular saw machine equipment is usually composed of modules such as machine bed, spindle system, feeding device, automatic feeding mechanism, clamping device and electrical control system. The spindle is driven by a high-power motor and equipped with a high-strength alloy saw blade. It can maintain stable cutting performance under high-speed rotation and is suitable for fast cutting of different materials. The feeding system works together with the servo motor and precision transmission components to control the cutting depth. At the same time, it has an automatic deviation correction function to ensure that the cutting surface is flat and smooth. The electrical control system is equipped with a programmable logic controller (PLC) or an industrial computer, which supports parameter preset, real-time monitoring and fault diagnosis. The operator can quickly adjust the cutting parameters through the human-computer interaction interface to adapt to diversified production needs.

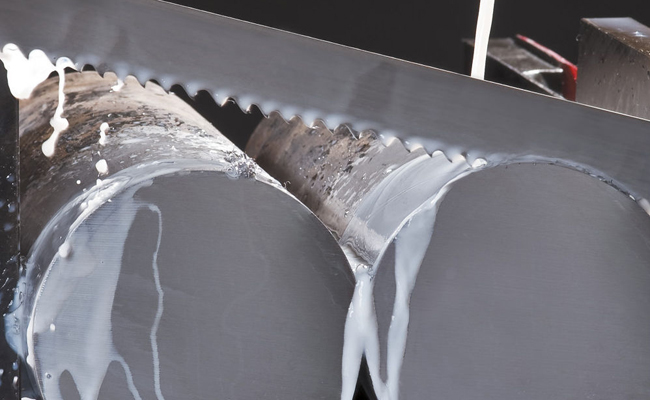

In terms of functional characteristics, automatic high-speed circular saw equipment has three core advantages: First, rapid automation, supporting continuous and uninterrupted operation, greatly reducing manual intervention; second, high-precision processing, through closed-loop feedback system and precision mechanical structure, can achieve micron-level cutting accuracy, meet the strict requirements of high-end fields such as aerospace and automobile manufacturing for the consistency of component size; third, multi-material adaptability, by replacing different types of saw blades or adjusting cutting parameters, it can flexibly respond to the processing needs of materials such as metal pipes, special-shaped steel, and engineering plastics. In addition, some models are also equipped with spray cooling systems and automatic chip removal devices to effectively reduce the risk of thermal deformation of saw blades while keeping the working area clean.

In terms of application scenarios, automatic high-speed circular saw machines are widely used in machinery manufacturing, construction materials, furniture production and other industries. In the field of metal processing, its fast cutting ability can significantly improve the feeding efficiency of pipes and bars; in wood processing, it can meet the special-shaped cutting needs of furniture panels. With the advancement of Industry 4.0, the equipment is gradually upgrading towards intelligence. In the future, it will further integrate Internet of Things technology to achieve remote operation and maintenance and real-time analysis of production data, providing key technical support for the transformation and upgrading of the manufacturing industry.

Cutting Capacity :

Cutting Capacity :