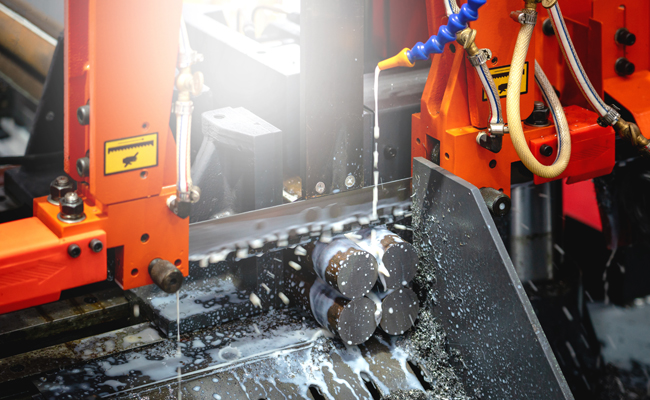

TGK-4240 Double Column Band Saw

Cutting Capacity :

Sawing skew is a common problem in the operation of band saws, involving many links. It not only involves the skills of the sawing machine operator, but also the adjustment of the sawing machine, but ultimately it is reflected in the saw blade’s serrated edge. Therefore, the tooth edge is the key to determining the cutting quality. When the band saw blade shows a deviation, immediately remove it and check its tooth tips. It turns out that each cutting edge of the new saw blade is like a sharp little shovel, but at this moment, you will see that one side of the tooth edge is white and bright. When you see that one side is blunt through a magnifying glass, there will be a deviation when sawing. The common issue is that the outer side becomes blunt. Due to poor clamping, the saw blade does not enter the vertical position, and the difficult side (mostly the outer side) is damaged. Now, let’s analyze the process of sawing diagonally;

Industry High Precision CNC Metal Bar Cutting Machine

1. Reasons for band sawing machine: Due to hydraulic system leakage, loss of control of the speed control valve and other reasons, the saw frame cannot be stably lowered (some low-cost sawing machines even have the saw frame vibrate during the cutting process), causing the saw blade to shake during cutting and resulting in the workpiece being sawn diagonally. In addition, if the distance between the two guide arms of the sawing machine is too large, the tension of the saw band is insufficient, the guide block is worn, and the saw band clamping is poor, it will directly affect the sawing quality and then extend the sawing slope.

2. Personnel operation reasons: We will focus on introducing the saw skew caused by improper operation. The saw skewing ratio caused by operation accounts for more than 90%. The typical manifestations are: installing a new saw band without any inspection or adjustment, let alone the initial running-in of the new saw blade, and using high-speed cutting. Due to the relatively large cutting feed rate, the sawtooth is in the limit cutting state. Under such circumstances, as the new sawtooth edge is extremely sharp, there are also burrs and slight allowable deviations during the processing. If the new saw blade does not run slowly, the tooth edge will wear out prematurely or on one side, and the gear division will be damaged. Therefore, new saw blades may show sawing skew or even collapse.

The correct operation is as follows: After tensioning the saw, measure the vertical accuracy of the saw, adjust the guide arm to a distance of approximately 1 centimeter from the workpiece (to prevent the saw from tilting, reduce the degree of saw distortion, and extend the saw’s service life), and lock the guide block. When sawing, when the saw teeth come into contact with the workpiece, they must be fed slowly (during the initial running-in stage) to ensure that the saw teeth are not subjected to excessive diving cutting force. Only when the saw teeth safely pass through the running-in period can normal cutting be carried out.

3. Reasons related to the band saw blade itself: As a daily cutting consumable, the purchase price management of band saw blades is generally strict. However, excessive price comparison can lead to more or less quality problems with the purchased saw blades, such as the blade body being prone to cracking and the tooth tips of the saw blade being prone to tooth loss. Among them, the blade body of the saw blade is relatively soft, which is also one of the main reasons for the material cutting tilting. Therefore, during the process of purchasing saw blades, buy more of those that are considered reasonably priced, then conduct tests, and after the tests, make large-scale purchases. At the same time, it should also be noted that the saw blades in the market are rather chaotic. It is better to go to a regular saw blade sales office to avoid passing off inferior products as good ones.

The above are the three major reasons for the sawing machine causing sawing skew. We believe that by knowing the last two reasons, everyone can try to avoid the human factors that cause sawing skew. As for the first reason caused by the band sawing machine, you can choose the band sawing machine produced by our company. Welcome to call for consultation.

Cutting Capacity :

Cutting Capacity :