G4240/70Z Angle Cutting Band Saw Machine

Cutting Capacity :

When sawing stainless steel, the saw blades always tear and break, which is too much of a waste of saw blades! What is the reason for this? What is a good solution? The experienced master will give you some advice.

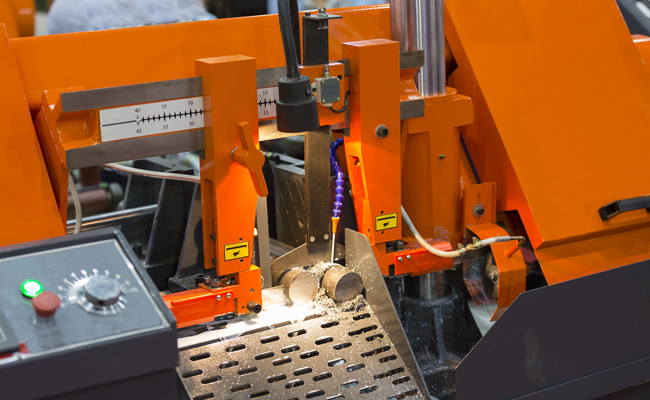

band saw cutting tool steel bar by automatic feed

1. Improper selection of saw blades

Problem:

The saw blade material is not hard enough (such as ordinary carbon steel saw blades cutting stainless steel).

The tooth shape or tooth pitch does not match (such as too large tooth pitch leads to stuck teeth, too small tooth pitch leads to poor chip removal).

Solution:

Choose carbide saw blades (such as bimetallic M42 or tungsten steel saw blades), which are resistant to high temperatures and wear.

Adjust the tooth pitch: It is recommended to choose fine teeth (such as 18-24 teeth per inch) to ensure that at least 3 teeth are in contact with the workpiece at the same time.

2. Incorrect cutting parameter settings

Problem:

The feed pressure is too high or the speed is too fast, resulting in overload of the saw blade.

The linear speed is too high (stainless steel has poor thermal conductivity and is prone to local overheating).

Solution:

Reduce feed pressure: Stainless steel needs to be cut smoothly to avoid forced advancement.

Adjust line speed: 15-30 m/min (high-speed steel saw blade) or 20-40 m/min (carbide saw blade) is recommended.

Use coolant: reduce friction heat and extend saw blade life (emulsion or special stainless steel cutting fluid is recommended).

3. Sawing operation problems

Problem:

The workpiece is not fixed firmly, and vibration causes saw blade teeth to break.

Sudden change in sawing angle (such as uneven force when cutting special-shaped parts).

Solution:

Strengthen the workpiece: Use a clamp to ensure no shaking.

Maintain uniform feed speed: Avoid impact loads, especially when cutting thick-walled pipes or special-shaped materials.

4. Poor equipment or saw blade condition

Problem:

The guide arm of the sawing machine is worn and the saw blade is deviated.

The saw blade tension is insufficient or too high (causing breakage or bevel cutting).

Solution:

Check the equipment: adjust the gap of the guide arm to ensure that the saw blade is perpendicular to the workpiece.

Calibrate the tension: set according to the manufacturer’s requirements (usually 300-400 N/mm²).

5. Influence of stainless steel characteristics

Problem:

Stainless steel (such as 304, 316) has a strong tendency to work hardening, and chips are easy to adhere to the saw teeth.

Solution:

Clean the chips in time: avoid secondary cutting to damage the saw teeth.

Give priority to sharp new saw blades: Severely worn saw blades will aggravate hardening.

6. Other precautions

Saw blade running-in: The parameters of the new saw blade need to be lowered for the first few uses.

Segmented cutting: Thick materials can be cut in stages to avoid continuous high temperatures.

Quick troubleshooting steps

Check whether the saw blade is compatible with stainless steel cutting.

Reduce the feed speed and pressure to observe whether it improves.

Add coolant and clean the chips.

Check the equipment tension and guide device.

If the problem still cannot be solved, it is recommended to contact the saw blade supplier for specific materials and technical support. Stainless steel cutting has high requirements for saw blades and equipment, and fine adjustments can usually significantly improve the problem.

Cutting Capacity :

Cutting Capacity :