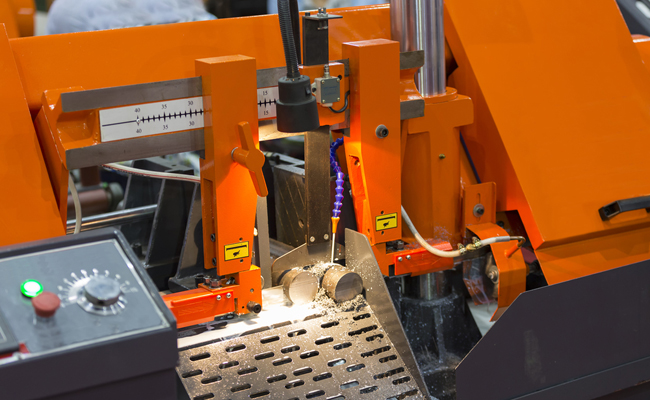

BS-460GB Horizontal Band Saw

Cutting Capacity :

In modern manufacturing industry, with the rapid development of automation technology, fully automatic circular saw machine has become a tool for many enterprises to improve production efficiency and reduce costs. The processing steps of fully automatic circular saw machine are the core of the high-efficiency operation of this equipment. Understanding its work flow and processing principle can not only help operators better master the use of equipment, but also effectively improve processing accuracy and work efficiency. With its accurate and fast cutting ability, fully automatic circular saw machine is widely used in the field of precision processing of materials such as wood, metal, and plastic. Therefore, mastering its processing steps is crucial to optimizing the production process.

band saw cutting tool steel bar by automatic feed

1. Preparation: Ensure the normal operation of the equipment

Before starting the processing of fully automatic circular saw machine, you first need to conduct a comprehensive inspection and preparation of the equipment. Ensure that the basic facilities such as power supply and air source of the equipment are operating normally, and conduct necessary inspections on various components of the equipment. For circular saw machine, the saw blade is the core part, so it is necessary to check the sharpness and installation of the saw blade. If the saw blade is damaged or worn, it should be replaced or repaired in time to ensure the accuracy of the cutting effect.

In addition to checking the saw blade, the operator also needs to set reasonable cutting parameters such as cutting speed, feed rate and cutting depth according to the type and thickness of the processed material. These settings will directly affect the processing quality and production efficiency, so they need to be adjusted accordingly according to different production needs.

2. Automatic feeding: accurate positioning and feeding control

An important advantage of the fully automatic circular saw machine is its automatic feeding function. The automatic feeding system can automatically feed the raw materials into the cutting area according to the set processing program. The operator needs to set the speed and length of the automatic feeding according to the size and processing requirements of the material. Ensure that the material can be accurately delivered to the saw blade to achieve the ideal cutting effect.

In the feeding process, the positioning system of the machine plays a key role. Through precise photoelectric sensors or laser positioning systems, the automatic feeding system can ensure that the material can be accurately aligned with the cutting position every time, thereby avoiding deviations. The accuracy of automatic feeding not only improves processing efficiency, but also significantly improves the quality of cutting, so that each product can maintain a consistent size and shape.

3. Cutting process: high-efficiency and accurate automatic cutting

Once the material enters the cutting area, the fully automatic circular saw machine begins to perform the cutting operation. The cutting process is a critical step that directly determines the processing quality and production speed. In this step, the machine’s automation system will control the saw blade’s speed, feed speed and cutting depth according to the preset cutting parameters to ensure the accuracy of each cut.

The fully automatic circular saw machine is equipped with a high-precision transmission system and power drive device to ensure that the saw blade maintains a stable operating state during the cutting process. While cutting, the equipment will automatically adjust the cutting pressure according to the nature and thickness of the material to avoid material deformation or saw blade damage caused by excessive pressure.

It is worth noting that many high-end fully automatic circular saw machines also have an intelligent feedback system. When an abnormal situation is found, the system will promptly alarm or automatically stop working to ensure the safety and stability of the processing process. This intelligent control system greatly reduces manual intervention and improves production efficiency and processing accuracy.

4. Automatic unloading: high energy efficiency sorting and processing continuity

After cutting, the automatic unloading system of the fully automatic circular saw machine will automatically remove the cut materials from the cutting area and send them to the designated storage area. Automatic unloading not only reduces the need for manual operation, but also ensures the orderly stacking of materials, avoiding damage or waste caused by improper manual handling.

For some products with special shapes or requiring secondary processing, the unloading system can also be customized according to different needs. Whether it is conventional straight-line cutting or complex multi-angle cutting, the automatic unloading system can accurately classify and stack the processed products to ensure the smooth progress of subsequent processing steps.

5. Quality inspection: ensuring processing accuracy

Although the processing process of the fully automatic circular saw machine has achieved a high degree of automation, quality inspection is still an important link that cannot be ignored. The fully automatic circular saw machine is usually equipped with a high-precision measuring device, which can monitor the cutting accuracy in real time during the processing process. Through sensors, cameras and other equipment, the system can detect parameters such as cutting position and dimensional deviation in real time, and adjust the processing process according to the detection results to ensure the quality of each product.

In some areas with high-precision processing requirements, the combination of manual inspection and automated testing can further improve the product qualification rate. Through the quality control of each batch of products, the high standards and consistency of the final product are ensured.

6. Equipment maintenance: ensuring long-term and stable operation of the equipment

In order to ensure the long-term and stable operation of the fully automatic circular saw machine, daily equipment maintenance and care are also crucial. Regular inspection and cleaning of various parts of the equipment and timely replacement of worn parts can effectively extend the service life of the equipment and maintain its processing accuracy.

The degree of wear of the saw blade should be checked regularly, and repaired or replaced according to the situation to ensure that the cutting quality is not affected. In addition, the lubrication system of the equipment also needs to be kept in good condition to avoid mechanical damage caused by lack of lubrication.

The processing steps of the fully automatic circular saw machine cover a series of processes from material preparation, automatic feeding, accurate cutting to automatic unloading, quality inspection, etc. The whole process is highly automated and intelligent, which not only improves the processing efficiency, but also ensures the processing quality. Through accurate cutting parameter setting, automatic feeding and unloading system, and intelligent feedback mechanism, the fully automatic circular saw machine can provide high-precision and high-efficiency solutions in the processing of various materials. Mastering these steps and properly configuring and maintaining equipment can significantly improve production capacity and reduce costs, and is an indispensable tool in modern manufacturing.

Cutting Capacity :

Cutting Capacity :