BS-712N Belt Drive Bandsaw

Cutting Capacity :

In modern industries such as metal processing, construction, and machinery manufacturing, fully automatic profile cutting machines have become essential equipment for enhancing productivity due to their efficiency, precision, and labor-saving advantages. However, with numerous models available on the market, how do you choose the most suitable one for your needs? This article provides a detailed guide on the key factors to consider when selecting a fully automatic profile cutting machine to help you make an informed decision.

1. Core Advantages of Fully Automatic Profile Cutting Machines

Compared to traditional manual or semi-automatic cutting equipment, fully automatic profile cutting machines offer the following benefits:

High Efficiency – Automatic feeding, cutting, and unloading significantly increase processing speed.

High Precision – CNC-controlled cutting ensures dimensional accuracy within ±0.1mm.

Labor-Saving – Reduces manual operation, lowering labor intensity and production costs.

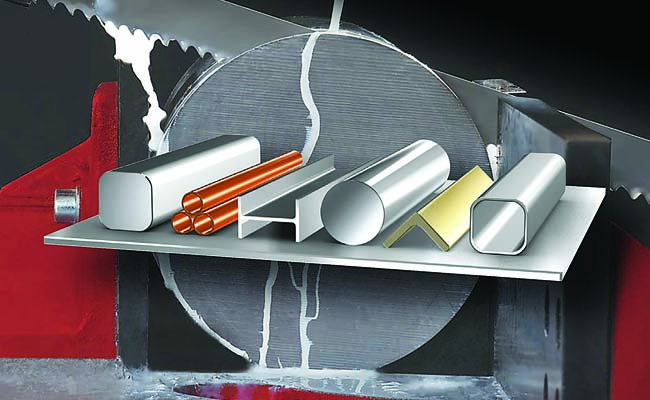

Strong Adaptability – Can cut various profiles, including metal (aluminum, steel, copper), plastic, and composite materials.

2. Key Factors in Choosing a Fully Automatic Profile Cutting Machine

1. Material and Thickness to Be Cut

Different materials require different machine specifications:

Metal Profiles (aluminum, steel, stainless steel): Require high-power (≥2000W) machines with specialized blades (e.g., carbide-tipped saw blades).

Plastic/PVC Profiles: Can use high-speed toothed saws or laser cutting machines.

Cutting Thickness: The machine must support the maximum cutting dimensions (e.g., Φ200mm round pipes or 150×150mm square tubes).

2. Cutting Method

| Cutting Method | Best For | Pros | Cons |

|---|---|---|---|

| Circular Saw Cutting | Metal, plastic | Fast, cost-effective | May produce burrs |

| Band Saw Cutting | Thick-walled metal | Smooth cuts, long blade life | Slower speed |

| Laser Cutting | High-precision thin materials | Non-contact, ultra-precise | Expensive equipment |

| Plasma Cutting | Thick steel plates | Strong cutting ability | Rough cut edges |

3. Automation Level

Basic Automation: Auto-feeding + cutting, suitable for simple production lines.

Full CNC Automation: Equipped with a CNC control system for programmable cutting patterns, ideal for complex processing.

Robotic Integration: Combined with robotic arms for fully automated loading/unloading, suitable for unmanned workshops.

4. Core Performance Specifications

Motor Power: Typically 3kW–7.5kW; higher power enables stronger cutting capacity.

Cutting Accuracy: CNC models can achieve ±0.05mm, standard models ±0.2mm.

Cutting Speed: Affects production efficiency, usually 10–50 cuts per minute (varies by material).

Feeding Length: Determines maximum workpiece length (e.g., 6 meters or custom longer sizes).

5. Brand and After-Sales Service

International Brands (High precision, durability):

Germany: TRUMPF, Messer

Japan: Amada, Komatsu

USA: Hypertherm, Lincoln Electric

3. Buying Recommendations by Application

| Application | Recommended Machine | Key Features |

|---|---|---|

| Small Workshops | Domestic CNC circular saw cutter | Affordable, ideal for aluminum profiles and steel pipes |

| Metal Fabrication | Fully automatic band saw cutter | Best for thick-walled steel, smooth cuts |

| High-Precision Work | Fiber laser cutting machine | Suitable for stainless steel and precision parts |

| Mass Production | Robotic cutting line | Fully automated, 24/7 operation |

4. How to Test and Inspect the Machine?

Test Cutting: Check for smooth, burr-free cuts.

Measure Accuracy: Use calipers or laser measuring tools to verify dimensional tolerance.

Observe Stability: Ensure minimal vibration and noise during operation.

Test Automation: Verify smooth functioning of auto-feeding, clamping, and cutting cycles.

When selecting a fully automatic profile cutting machine, consider material type, cutting precision, automation level, brand reputation, and after-sales service. For small-scale production, an economical CNC circular saw is sufficient. For high-precision metal cutting, laser or plasma cutters are preferable. Large enterprises should consider robotic integration for full automation.

Cutting Capacity :

Cutting Capacity :