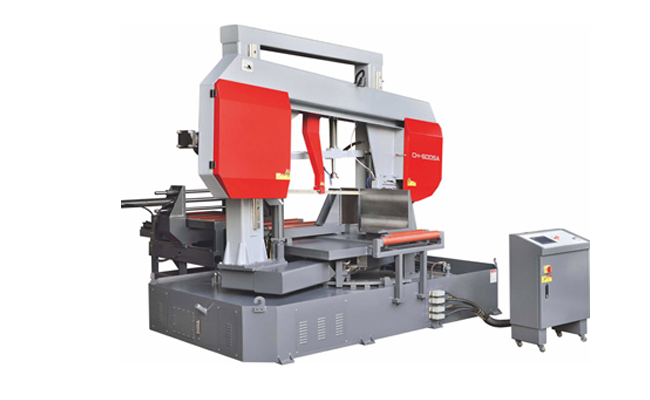

BS-650G Horizontal Band Saw

Cutting Capacity :

In the realm of industrial manufacturing and metal fabrication, efficiency, precision, and raw cutting power are paramount. Among the arsenal of cutting tools available, the Industrial Horizontal Band Saw stands as a cornerstone technology for primary stock cutting operations. Designed for reliability and high throughput, this machine is engineered to perform repetitive, straight cuts on large bundles of material or individual large-diameter stock with minimal operator intervention.

This guide delves into the intricacies of the industrial horizontal band saw, exploring its fundamental principles, operational advantages, inherent limitations, and the key applications where it proves indispensable.

An Industrial Horizontal Band Saw is a heavy-duty, stationary power saw where the band blade, a continuous loop of serrated steel, runs on two or more large wheels in a horizontal plane. The cutting action is characterized by the downward (or sometimes horizontal) motion of the blade assembly onto a stationary workpiece that is securely clamped in a vise.

Unlike its vertical counterpart, the primary orientation of the machine is low-profile, with the blade traveling parallel to the floor. These machines are built for ruggedness, often featuring reinforced frames, high-torque drive systems, and sophisticated hydraulic or CNC-controlled feed mechanisms. They are the workhorses of steel service centers, forging plants, and any facility requiring the dematerialization of long bars, tubes, and structural shapes into manageable blanks.

The operation of an industrial horizontal band saw is a systematic, automated process:

Material Loading: The operator places the raw material (e.g., a long bar, pipe, or a bundle of tubes) onto the machine’s bed or feeding table.

Vise Clamping: A powerful hydraulic vise closes, securely gripping the material to prevent movement during the cut. On advanced models, the vise can be programmed to index the material automatically for multiple cuts of the same length.

Cutting Cycle Initiation: The operator initiates the cycle, often via a programmable logic controller (PLC) interface.

Feed and Cut: The entire blade assembly, including the wheels and the guided blade, moves downward (in a pivot or fall-arm design) or forward (in a dual-column design) with controlled hydraulic or servo pressure. The continuous band blade slices through the material.

Automatic Shut-off: Upon complete penetration, a limit switch or sensor is triggered, stopping the blade and retracting the saw head.

Part Ejection and Indexing: The vise opens, and on automated systems, the cut piece is ejected, and the material is automatically indexed forward for the next cut. The cycle repeats until the programmed number of pieces is produced.

This “set-and-forget” operational sequence is key to its high productivity.

The design of the horizontal band saw confers several critical advantages in an industrial context:

High Degree of Automation: Once set up, these machines can run unattended for hours, producing hundreds of identical cut pieces. This frees up skilled operators for other tasks.

Exceptional Throughput and Productivity: They are significantly faster than manual saws for straight cuts on multiple pieces. Capable of processing entire bundles of material in a single pass, they are unmatched in volume production.

Superior Capacity: Industrial horizontal band saws are available in massive sizes, capable of cutting solid rounds or rectangular stock with cross-sections exceeding 24 inches (600 mm) and more.

Enhanced Safety: The enclosed cutting area, fixed workpiece, and automated cycle minimize operator interaction with the blade, leading to a much safer working environment compared to manual sawing.

Material and Labor Efficiency: Precise indexing and straight cutting minimize kerf loss (material lost as sawdust). The automated nature reduces direct labor costs per part.

Consistent, High-Quality Cuts: The controlled feed pressure and robust blade guidance systems ensure square, burr-minimized cuts with excellent surface finish, which is crucial for subsequent machining operations.

Despite their power, horizontal band saws have specific limitations that must be acknowledged:

Limited to Straight Cuts: They are fundamentally designed for straight, 90-degree cuts. Complex shapes, contours, or notches are impossible to produce.

Significant Floor Space: Due to their long bed requirements for handling full-length stock, they consume considerable floor space in a workshop.

Higher Initial Investment: A fully-featured CNC horizontal band saw represents a substantial capital investment compared to a basic vertical model or a cold saw.

Setup Time for Small Batches: While excellent for long runs, the programming and setup time may not be justifiable for one-off or very small batch jobs, where a vertical band saw might be more agile.

Industrial Horizontal Band Saws are the preferred solution in a wide array of sectors:

Steel Service Centers and Metal Warehouses: For cutting down long bars, beams, channels, and pipes to customer-specified lengths.

Forging and Casting Industries: Preparing billets and blanks from large-diameter round or square stock for subsequent hot or cold forming.

Shipbuilding and Heavy Machinery: Cutting large structural components, shafts, and thick-walled pipes.

Automotive and Aerospace Manufacturing: Producing precise blanks from high-strength alloys, titanium, and other exotic materials for further CNC machining.

Pipe and Tube Processing: Bundled cutting of multiple tubes for furniture, automotive exhausts, or structural frameworks.

When selecting an industrial horizontal band saw, key specifications must be evaluated. The following table provides a comparative overview of common industrial models:

Table: Industrial Horizontal Band Saw Technical Comparison

| Feature / Specification | Standard Manual / Semi-Auto | CNC Fully-Automatic | High-Capacity CNC |

|---|---|---|---|

| Typical Capacity (Solid Round) | 10″ – 16″ (250 – 400 mm) | 12″ – 20″ (300 – 500 mm) | 20″ – 36″+ (500 – 900+ mm) |

| Blade Size (Length x Width) | ~ 14′ x 1.25″ (4.3m x 32mm) | ~ 16′ x 1.5″ (4.9m x 38mm) | 20’+ x 2″ (6m+ x 50mm) |

| Control System | Manual or Basic PLC | Full CNC with Touchscreen | Advanced CNC with Network Connectivity |

| Material Feeding | Manual Indexing | Servo-driven, Automatic Indexing | Servo-driven with Bundle Clamping |

| Primary Advantage | Cost-effective for medium batches | High productivity, unattended operation | Massive capacity for heavy industry |

| Ideal Use Case | Job shops, repair facilities | High-volume production lines | Steel mills, forging plants, large fabricators |

| Approx. Power (Motor) | 5 – 10 HP | 10 – 15 HP | 15 – 25+ HP |

Cutting Capacity :

Cutting Capacity :