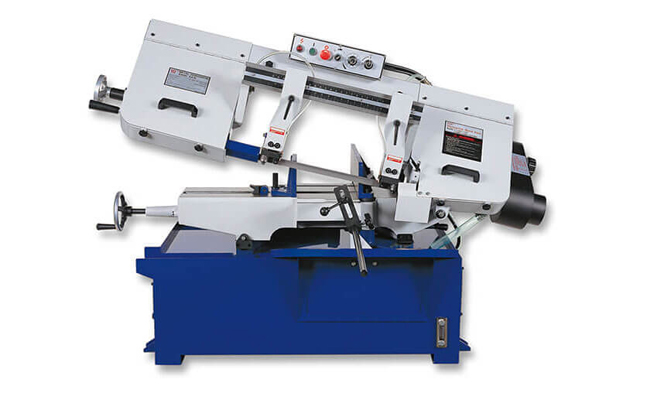

BS-5030 Horizontal Metal Cutting Bandsaw

Cutting Capacity :

In the field of modern metal processing, the dual pursuit of efficiency and precision has given rise to the birth of various advanced equipment. As an intelligent upgraded version of the traditional sawing machine, the multi-angle cutting band sawing machine is reshaping the boundaries of metal cutting technology with its unique processing flexibility and excellent cutting performance. This equipment can not only complete conventional right-angle cutting, but also achieve precision cutting at various angles, providing unprecedented convenience for complex workpiece processing.

1. Analysis of the core technology of multi-angle cutting band sawing machine

The reason why the multi-angle cutting band sawing machine can surpass the traditional sawing machine is that it integrates a number of advanced technologies.

The servo drive system constitutes the core power source of the equipment. Compared with traditional hydraulic or mechanical drives, the servo system provides more precise speed control and position positioning, allowing the saw blade to maintain constant tension during the cutting process, which is particularly important for angle cutting. When non-90-degree cutting is performed, the contact area and force distribution between the saw blade and the workpiece will change. The servo system can adjust the output power in real time to ensure the stability of the cutting process.

The CNC angle positioning device is another key technological breakthrough of this type of equipment. Through the cooperation of high-precision encoders and CNC systems, the saw table or saw head can make precise angle adjustments in multiple axes. Modern high-end models are usually equipped with a touch screen interface. The operator only needs to enter the required angle value, and the system will automatically complete the position adjustment with an accuracy of ±0.1 degrees, which fully meets the processing requirements of high-precision industries such as aviation and molds.

The intelligent cutting control system is like the brain of the equipment, continuously monitoring various parameters during the cutting process. Through force feedback sensors and vibration monitoring devices, the system can adjust the feed speed and saw blade speed in real time, especially when performing angle cutting, automatically compensating for the difference in cutting resistance caused by angle changes. Some advanced models also have adaptive learning functions that can automatically optimize cutting parameters according to material characteristics.

The design of the modular tool system enables the equipment to quickly replace saw blades of different specifications to meet various processing needs from thin-walled pipes to large castings. The specially designed saw blade guide device provides additional support during angle cutting to prevent the saw blade from swinging and ensure the smoothness of the cut surface.

2. Detailed description of equipment structure and functional features

The structural design of the multi-angle cutting band saw machine fully considers the diversity and complexity of industrial applications, and each part embodies the crystallization of engineering wisdom.

The main frame is usually made of high-grade cast iron or welded steel structure, which has been optimized by finite element analysis and has extremely high static and dynamic rigidity. This solid foundation ensures that the equipment will not deform or vibrate due to asymmetric force when cutting at an angle. Large models are often equipped with foundation mounting holes to further enhance stability.

The double-column structure is a typical feature of high-end models. It is like the “spine” of the equipment, supporting the weight of the entire sawing system. The column is equipped with a pre-tightened linear guide rail to ensure that the saw frame maintains absolute vertical accuracy during the lifting process. When cutting at an angle, the double-column structure can effectively resist lateral forces and prevent the saw frame from twisting.

The rotating table system is a key component to achieve multi-angle cutting. The precision-made turntable bearing allows the table to rotate ±45 degrees or even more in the horizontal plane, while the tilt function enables the table to adjust the angle in the vertical plane. The combination of dual angle adjustment capabilities allows the workpiece to be fixed at almost any spatial angle for cutting. The worktable surface is usually machined with regular T-slots or threaded holes to facilitate the installation of various clamps.

Hydraulic or pneumatic clamping devices provide strong workpiece fixing force, especially suitable for the asymmetric cutting forces generated during angle cutting. Intelligent clamping systems can automatically adjust the clamping force according to the shape and size of the workpiece, ensuring a firm fixation and avoiding deformation of the workpiece. Some systems also have anti-collision detection functions, which warn when the saw blade and the clamp may interfere.

Automatic feeding systems greatly improve batch processing efficiency. Roller or clamp feeding mechanisms work synchronously with the main control system to accurately control the feeding length and repeat positioning accuracy up to 0.05mm. For angle cutting, the feeding system will intelligently adjust the feed direction to ensure that the geometric relationship of each cut is consistent.

The cooling and lubrication system is specially optimized for the characteristics of angle cutting. The adjustable angle nozzle ensures that the cutting fluid can accurately reach the contact area between the saw blade and the workpiece, even when cutting at an elevation or depression angle. Efficient filtering devices extend the service life of cutting fluids while keeping the working environment clean.

3. Expansion and innovation in application areas

The application of multi-angle cutting band saws has far exceeded the scope of traditional metal processing industries, and its unique capabilities are creating new possibilities in many fields.

In aerospace manufacturing, this equipment is used to process titanium alloy structural parts and aviation aluminum. Many connecting parts in the aircraft skeleton require precise bevel interfaces. Traditional processes require sawing and then milling, while multi-angle band saws can be formed in one go, saving more than 30% of processing time. After adopting such equipment, an aviation parts supplier reduced the processing steps of a certain type of bracket from 5 to 2, and the yield rate increased by 15%.

Chassis component manufacturing in the automotive industry also benefits from this technology. Safety-critical components such as control arms and steering knuckles often require cutting surfaces at specific angles to meet force requirements. Multi-angle band saws not only ensure cutting accuracy, but their cold cutting characteristics also avoid damage to material properties in the heat-affected zone. After a German car brand introduced such equipment in its chassis production line, the processing cost per piece was reduced by 22%.

In the field of energy equipment manufacturing, such as tower connectors of wind turbines, large-sized bevel structures are usually used. Traditional flame cutting or plasma cutting can hardly guarantee the quality of the bevel, while large multi-angle band saws can complete the precise beveling of steel plates with a thickness of more than 300mm at one time, with a bevel angle error of less than 0.5 degrees, greatly improving the welding quality and efficiency.

In the field of building steel structures, this equipment has revolutionized the node processing technology. Complex space truss connection nodes require multiple cutting surfaces at different angles. In the past, they needed to be manually marked and processed one by one. Now all cutting can be completed at one time through programming. After a certain international exhibition center project adopted a multi-angle band saw equipped with an automatic flip clamping system, the efficiency of steel structure node processing increased by 3 times.

The mold manufacturing industry has also discovered the unique value of this equipment. Mold templates often require insert slots and exhaust slots at various angles. Traditional processing relies on milling machines, which is time-consuming and has high tool costs. Multi-angle band saws use saw blades with special tooth shapes, which can directly cut high-precision grooves with a surface roughness of up to Ra3.2, fully meeting most mold requirements.

Even in the field of artistic creation, metal sculptors have begun to use this type of equipment. It can help achieve special angle combinations that are difficult to achieve with traditional tools, opening up new forms of expression for metal art creation. A series of works created by a well-known metal artist using a multi-angle band saw attracted widespread attention at last year’s international art exhibition.

4. In-depth analysis of technical advantages

Compared with traditional cutting equipment, multi-angle cutting band saws show a series of significant technical advantages, which are transformed into considerable economic benefits in practical applications.

In terms of processing accuracy, this type of equipment has reached an unprecedented level. According to laser interferometer measurement, when cutting a 100mm thick workpiece, the straightness deviation of high-end models does not exceed 0.1mm/m, and the angle deviation is less than 0.1 degrees. This accuracy comes from multiple guarantees: high-rigidity mechanical structure eliminates elastic deformation; pre-tightened linear guides reduce motion clearance; real-time closed-loop control system compensates for various error sources. Especially when performing compound angle cutting, the system automatically calculates and compensates for geometric errors caused by angle changes.

Efficiency improvement is another outstanding advantage. Comparative tests show that when processing workpieces with 30-degree bevels, the traditional process requires sawing and then milling the bevels, which takes about 25 minutes in total; while the multi-angle band saw only takes 8 minutes to form once, and the efficiency is increased by nearly 70%. When processing in batches, the advantages are more obvious with the automatic feeding system. A report from an automobile parts factory shows that after using a multi-angle band saw in the production of steering knuckles, the daily output increased from 120 to 210 pieces, while the number of operators was reduced by 1/3.

The significant increase in material utilization has brought direct cost savings. Due to the high angle cutting accuracy, the subsequent processing allowance can be omitted in many cases. Statistics show that in steel structure manufacturing, the use of multi-angle band saws can reduce material waste by 12-18%. For expensive special alloys, this saving is particularly valuable. A titanium alloy product manufacturer said that 6 months after the equipment was put into use, the material cost savings were equivalent to 30% of the equipment investment.

The improvement in surface quality reduces the need for subsequent processes. Optimized saw blade design and precise guide system enable the cut surface roughness to reach Ra6.3 or even better, and in many cases no milling or grinding is required. In pipe cutting applications, excellent cut quality ensures good fusion during welding, reducing pores and unfused defects. A pressure vessel manufacturer reported that the welding pass rate increased by 8 percentage points.

Flexibility is reflected in the rapid conversion capability of the equipment. To switch from one angle to another, the CNC model only needs to enter the new parameters on the control panel, and the conversion time does not exceed 2 minutes. This feature is particularly suitable for small batch and multi-variety production mode. In contrast, traditional methods require replacement of fixtures or adjustment of the template, which often requires 15-30 minutes of downtime.

Energy efficiency is also better than many traditional cutting methods. Test data shows that when cutting workpieces of the same specifications, the energy consumption of the multi-angle band saw is only 40% of the band saw plus milling machine combination, and 25% of plasma cutting. This energy efficiency advantage comes from the direct forming process that reduces the processing steps on the one hand, and the efficient energy utilization of the servo drive system on the other hand.

5. Professional Guide to Operation and Maintenance

To fully utilize the performance of the multi-angle cutting band saw, it is necessary to follow scientific operating procedures and maintenance specifications, which are summarized from the practical feedback of many users.

The selection of saw blades is the first step to successful cutting. For angle cutting, it is recommended to use a special saw blade for multi-angle cutting with a specially designed tooth shape. Such saw blades usually have a variable pitch and a special front angle design, which can effectively reduce vibration during cutting. In terms of materials, bimetallic saw blades are suitable for most applications, while carbide-tipped saw blades are suitable for high-hardness materials. Rule of thumb: Choose 3-4 teeth/inch when cutting aluminum alloy, 6-8 teeth/inch for carbon steel, and 10-12 teeth/inch for stainless steel.

Parameter optimization needs to be carried out according to specific circumstances. The initial setting can refer to the following principles: cutting speed—15-25m/min for mild steel, 8-15m/min for stainless steel, and 30-50m/min for aluminum alloy; feed pressure—usually blade width (mm) × 0.5-1.2kg/mm. When cutting at an angle, it is recommended to adjust the normal parameters down by 10-20%, especially when the cutting angle is greater than 30 degrees. The adaptive control system of modern equipment can make these adjustments automatically, but understanding the basic principles can help deal with abnormal situations.

Workpiece clamping is particularly critical for angle cutting. It is necessary to ensure that the workpiece is in full contact with the worktable, and any slight gap will cause angle deviation. For irregular-shaped workpieces, it is recommended to use special clamps or combined clamping systems. A practical tip: When cutting long workpieces, support should be added to the overhanging end to prevent the workpiece from shifting due to gravity during the cutting process. When cutting at compound angles, consider a step-by-step processing strategy, completing the angle cutting in one direction first, repositioning it, and then cutting in the other direction.

Daily maintenance points include: daily check of hydraulic system pressure (should be kept within ±5% of the set value); weekly cleaning and relubrication of the guide rails (using the specified brand of grease); monthly check of belt tension (should have 10-15mm deflection); quarterly calibration of the angle positioning system (verified using a precision angle gauge). It is particularly important to note that the coolant should be replaced regularly and maintained at an appropriate concentration. Contaminated or diluted coolant will significantly shorten the life of the saw blade.

Common troubleshooting problems include: angle deviation – check whether the clamp is loose and the guide rail is worn; rough cut surface – check the wear of the saw blade and whether the cooling is sufficient; abnormal vibration – check the tension of the saw blade and whether the foundation is stable. The equipment is usually equipped with a self-diagnosis system that provides detailed error code references. It is very helpful to establish a complete maintenance log, which can help discover the regularity of potential problems.

Safe operation must be strictly followed: the safety interlock device must not be bypassed at any time; the equipment must be completely stopped when adjusting the angle; a special tension meter must be used when replacing the saw blade; tools must be used instead of hands when cleaning chips. It is recommended to conduct safety refresher training for operators every six months, and new employees must complete more than 20 hours of practical training under supervision before they can operate independently.

6. Outlook on market development trends

Multi-angle cutting band saw machine technology is still developing rapidly, and more innovative breakthroughs are expected to appear in the next few years, further expanding the application boundaries.

Intelligence is a clear development direction. The next generation of equipment will integrate more sensors and AI algorithms to achieve true adaptive processing. The system under development can judge the state of the saw blade in real time through vibration spectrum analysis and predict the remaining service life; identify the difference in material properties through cutting sound and automatically fine-tune parameters; and even optimize the cutting path through machine learning to reduce empty strokes. The test model of a leading manufacturer has achieved “one-click” processing – the operator only needs to put in the workpiece, and the equipment automatically identifies the material and size and completes the optimal cut.

Composite processing capabilities will be enhanced. Future equipment may integrate auxiliary functions such as drilling and chamfering to truly achieve “one clamping, complete processing”. A design that is being patented integrates a rotating tool in the saw blade guide device, which can complete edge chamfering while cutting. Another conceptual design combines a 3D print head with a sawing system, creating a new model of “subtractive and additive hybrid manufacturing”.

Green manufacturing technology will be more valued. New low-energy drive systems are expected to reduce electricity consumption by 15-20%; dry cutting technology has made progress, and some materials may no longer need cutting fluids; a saw blade material recycling system is being established, with the goal of achieving a material reuse rate of more than 95%. A research project funded by the European Union has developed biodegradable cutting fluids that significantly reduce environmental burden while maintaining performance.

Service model innovation is changing the industry ecology. Remote monitoring and services based on the Internet of Things can detect potential problems in advance and reduce downtime; some manufacturers have begun to provide a “pay by cut” business model to reduce users’ initial investment; shared machining centers have emerged in industrial parks, allowing small and medium-sized enterprises to enjoy high-end equipment. According to industry analysis, by 2026, about 30% of equipment sales will be accompanied by some form of service contract.

Material adaptability continues to expand. Special saw blades for composite materials have been launched, which can cleanly cut carbon fiber reinforced plastics; breakthroughs have been made in the cutting of superhard materials, and the latest diamond-coated saw blades can process materials with a hardness of more than HRC70; there are even studies trying to use special saw blades to cut ceramic matrix composites. These developments are taking band saws beyond their traditional metalworking niche and into a wider world of materials.

Human-machine interaction is more natural and intuitive. Augmented reality (AR) technology has begun to be applied to equipment operation and maintenance. The cutting path and internal status can be intuitively seen through the head-mounted display; the voice control function allows the operator to adjust parameters when both hands are busy; the tactile feedback system allows remote operation to feel the change of cutting resistance. The concept machine displayed by a Japanese manufacturer can even interpret the operator’s gesture instructions.

Multi-angle cutting band saws represent a major leap in metal cutting technology. It breaks the angle limitations of traditional equipment and provides efficient and accurate solutions for complex parts processing. From aerospace to artistic creation, from mass production to personalized customization, this multi-functional equipment is redefining the possible boundaries of cutting technology. With the continuous development of intelligent and composite technologies, multi-angle cutting band saws will play a more important role in the field of precision manufacturing and become an indispensable processing tool for modern factories. For companies pursuing efficiency and quality, investing in such advanced equipment is not only an upgrade of production tools, but also an innovation of manufacturing concepts, which will provide key technical advantages in the increasingly fierce market competition.

Cutting Capacity :

Cutting Capacity :