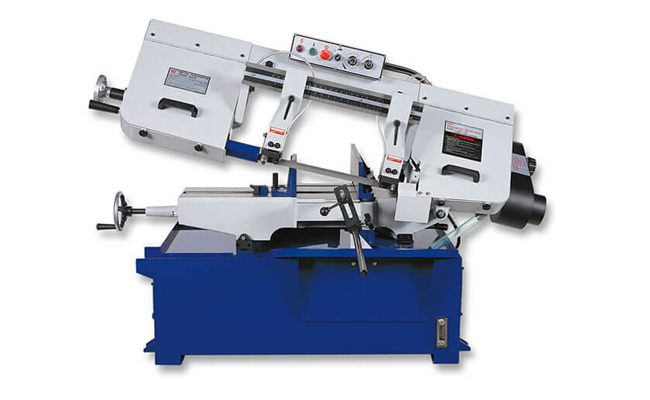

BS-1018TH Metal Cutting Bandsaw

Cutting Capacity :

It is inevitable that sawing machines will fail due to improper operation or disrepair. In order to increase the service life of sawing machines, we must do a thorough cleaning and maintenance of sawing machines in daily work, and regularly inspect and repair them. So what are the common types of faults in sawing machines?

1. The cutting surface is rough or beveled

It is usually due to the blunting of the saw teeth of the band saw blade, the damage of the tooth tip, or the failure of the sawing machine operator to adjust the tension and feed speed of the saw blade. It can be solved by replacing new saw blades, detecting the tension of the saw blade, adjusting the feed rate, and adjusting the position of the workpiece and the guide arm.

2. The sawing machine oscillates during operation

The reasons for the oscillation of the sawing machine are probably: incorrect tooth selection, workpiece not clamped, hydraulic system failure, lubrication system failure, etc. The treatment method is: ask the technician whether the tooth type is used correctly, check whether the workpiece is clamped firmly, and the hydraulic system and lubrication system should be maintained regularly.

3. The saw blade is blunted, stuck, pulled, cracked, etc.

The band saw blade is a consumable. After a period of use, the teeth will become blunt. After the tooth tip is blunt, it can be removed for grinding or replaced with a new saw blade. If the new saw blade is stuck, pulled, cracked, etc., it should be considered whether the wrong saw blade material or saw blade tooth type is used, resulting in excessive sawing load. In addition, check whether there is foreign matter accumulation on the gear, which affects the force of the saw blade.

4. Sawdust adhesion

Customers may encounter sawdust sticking to the saw blade. The solution is: choose the appropriate cutting fluid, water-oil ratio (high alloy 5:1/low alloy, carbon steel 10:1), check the steel brush responsible for cleaning on the sawing machine, and replace it.

5. The sawing machine whistles during cutting

When a harsh sound occurs during operation, it may be due to excessive speed or excessive feed, insufficient coolant on the sawing machine, too tight guide block, hard impurities in the material, etc.

6. Failures caused by failure to replace consumable parts and regular inspection and maintenance

When the sawing machine is unstable, the lifting cylinder cannot stop automatically, the speed regulating valve is faulty, there is foreign matter or air in the hydraulic cylinder, the cylinder is leaking oil, the solenoid valve is faulty, there are loose screws, etc., it is usually due to aging or inflexible operation of various parts of the sawing machine. The solution is: If you have no knowledge and experience in band sawing machine maintenance, you should find a maintenance person in time when the sawing machine has the above problems, or communicate with the band sawing machine manufacturer in time.

Cutting Capacity :

Cutting Capacity :