BS-912G Metal Cutting Bandsaw

Cutting Capacity :

A bandsaw is an indispensable tool in metalworking and lumber processing, characterized by a continuous band of toothed metal stretched between two or more wheels. Among the various types, the Double Column Semi-Automatic Horizontal Bandsaw represents a significant evolution from basic horizontal models, offering a blend of robust construction, enhanced precision, and operational efficiency. This machine is engineered for demanding industrial environments where repeatability, accuracy, and minimal operator intervention are paramount.

This article delves into the specifics of the Double Column Semi-Automatic Horizontal Bandsaw, exploring its components, working principles, advantages, limitations, and ideal applications.

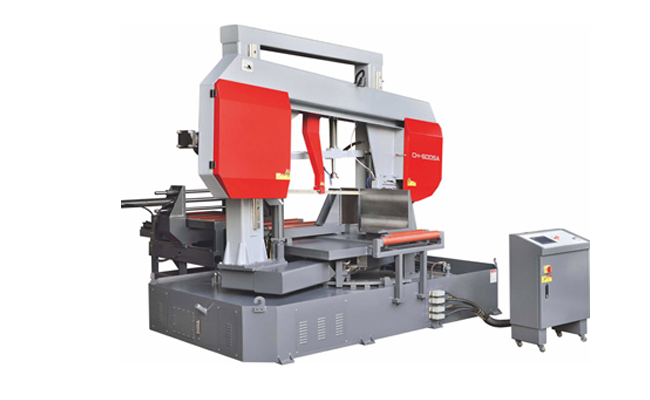

Industry High Precision CNC Metal Bar Cutting Machine

A Double Column Semi-Automatic Horizontal Bandsaw is a heavy-duty cutting machine designed primarily for straight, high-precision cuts on large metal stock, such as billets, bars, and profiles. The name derives from its key features:

Double Column: The saw frame, which holds the band wheels and blade, moves up and down on two massive, parallel vertical columns. This design provides exceptional rigidity and stability, minimizing deflection during cutting and ensuring consistent accuracy across the entire workpiece.

Horizontal: The cutting action is horizontal, meaning the blade travels in a vertical plane, and the cutting head (or the material) feeds downward into the stationary workpiece.

Semi-Automatic: The machine automates the critical phases of the cutting cycle—clamping the material, advancing the blade, cutting, and retracting—based on pre-set parameters. However, an operator is required to load/unload material and initiate the cycle, offering a perfect balance between automation and flexibility.

Understanding the components is crucial to appreciating its capabilities:

Double Column Frame: The foundation of the machine, providing vibration-dampening and resistance to torsional forces.

Vise Clamping System: A powerful hydraulic or pneumatic vise that securely holds the workpiece from both sides, preventing movement and ensuring a square cut.

Semi-Automatic Control Panel: Typically a CNC (Computer Numerical Control) or PLC (Programmable Logic Controller) interface allowing the operator to set cutting length, feed rate, blade speed, and pressure.

Material Feed System (Stock Stop): A precision linear scale or servo-driven stop gauge that automatically positions the material to the desired cut length.

Coolant System: An integrated system that delivers cutting fluid to the blade-teeth/workpiece interface, reducing heat, extending blade life, and improving cut quality.

Chip Conveyor: An automated mechanism (often a helical screw) to remove swarf (metal chips) from the cutting area, enhancing cleanliness and continuous operation.

The cutting process is a precisely choreographed sequence:

Loading: The operator places a bundle or a single piece of stock against the material feed stop.

Clamping: The operator initiates the cycle. The hydraulic vise closes, firmly securing the material.

Cutting: The saw frame, driven by a hydraulic or ball-screw mechanism, descends with a controlled feed rate. The continuous bandsaw blade cuts through the material.

Return: Once the cut is complete (often sensed by an amperage monitor or limit switch), the blade automatically stops, and the saw frame retracts to its home position.

Unclamping & Repetition: The vise opens. The operator can then index the next cut length, and the cycle repeats.

Superior Rigidity and Accuracy: The double-column design is the primary advantage. It virtually eliminates frame flex, guaranteeing straight cuts with excellent surface finish and tight tolerances (typically within ±0.1mm per 100mm of cut).

High Productivity: Semi-automation allows for rapid, consistent cycle times. The ability to process large bundles or long stock with minimal operator intervention significantly boosts throughput.

Reduced Operator Fatigue and Skill Dependency: Once the machine is programmed, the cutting process requires minimal physical effort or advanced skill from the operator, who primarily handles loading and monitoring.

Enhanced Safety: The cutting process is enclosed, and the automated cycle removes the operator’s hands from the blade path, drastically reducing the risk of injury.

Material Efficiency: Precise control over the cutting length and a thin kerf (the width of the cut) minimize material waste, which is critical for expensive alloys.

Versatility in Stock Size: Capable of handling a very wide range of material dimensions, from small bars to large rectangular billets exceeding 500mm in height.

High Initial Investment: These are capital-intensive machines, significantly more expensive than manual vertical or single-column horizontal bandsaws.

Fixed Cutting Geometry: Designed almost exclusively for straight cuts and miter cuts (if equipped with a mitering vise). They cannot perform the contouring or intricate shapes possible on a vertical bandsaw.

Floor Space Requirement: Their robust construction and long feed beds necessitate a substantial amount of factory floor space.

Limited “One-Off” Flexibility: While highly efficient for batch production, setting up for a single, unique cut can be less time-efficient than using a manual machine.

This machine is a staple in industries that require high-volume, precision cutting of metals:

Metal Service Centers: For cutting bar stock (round, square, hexagonal), structurals (I-beams, channels), and pipes to specific lengths for customer orders.

Forging and Foundries: Cutting billets and blanks to precise weights and dimensions for subsequent forging or casting processes.

Aerospace and Automotive Manufacturing: Preparing high-strength alloy steels, titanium, and aluminum for critical components where material integrity and cut quality are non-negotiable.

Heavy Machinery Production: Cutting large shafts, cylinders, and other massive components.

The following table provides a representative overview of the specifications for a mid-range Double Column Semi-Automatic Horizontal Bandsaw.

| Specification Category | Typical Range / Description | Notes |

|---|---|---|

| Max Cutting Capacity (Rectangular) | 300mm x 350mm to 600mm x 600mm+ | Refers to the maximum height and width of a solid block the machine can cut. |

| Max Cutting Capacity (Round) | Ø300mm to Ø650mm+ | |

| Blade Size (Length x Width) | 4,500mm x 34mm to 6,500mm x 54mm | Wider blades are generally more durable and resistant to deflection. |

| Blade Speed (Variable) | 15 – 120 meters per minute (m/min) | Optimized for different materials (e.g., low for hardened steel, high for aluminum). |

| Feed Control | Hydraulic or Servo-Electric (Ball Screw) | Servo-electric offers superior precision and programmability. |

| Control System | PLC with Digital Readout (DRO) or CNC | CNC allows for storing multiple job programs for different materials. |

| Miter Cutting Capability | ±0° to 45° (Left & Right) | An optional feature with a pivoting vise. |

| Accuracy (Straightness) | ≤ 0.1mm / 100mm | A key metric indicating the deviation from a perfectly straight line. |

| Primary Applications | High-volume cutting of bars, tubes, structurals, and billets. | Ideal for batch production and material preparation. |

Material Type and Size: The primary factor. The machine’s capacity must comfortably exceed your largest and hardest common workpieces (e.g., cutting high-tensile steel requires a more robust machine than aluminum).

Production Volume and Shift Operation: Justified for medium to high production runs. If running multiple shifts, consider features like automatic lubrication and heavy-duty components.

Required Accuracy and Finish: If your downstream processes demand near-net-shape cuts with minimal secondary processing, the rigidity and control of a double-column machine are essential.

Level of Automation: Evaluate if a semi-automatic model suffices or if your workflow demands a fully automatic system with integrated loading robots and conveyors.

Available Space and Power: Ensure your facility has the necessary floor space, electrical supply (typically 3-phase), and compressed air for the vise and controls.

In conclusion, the Double Column Semi-Automatic Horizontal Bandsaw is a precision-engineered solution that bridges the gap between manual operation and full automation. Its unparalleled rigidity, repeatability, and efficiency make it an invaluable asset for any serious metalworking operation focused on productivity, quality, and long-term return on investment.

Cutting Capacity :

Cutting Capacity :