CH-400SA Miter Band Saw Machine for I-beams H-beams

Cutting Capacity :

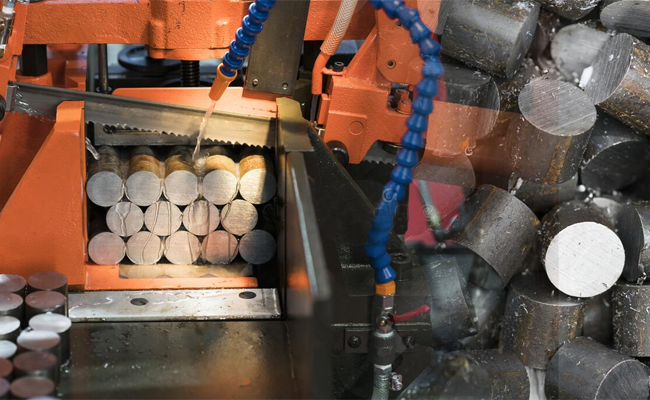

Band saws are essential tools in modern metalworking and woodcutting, widely used in industries such as machinery manufacturing, construction, and metallurgy. Their high efficiency and precision make them indispensable in workshops and factories. However, with various types of band saws available, selecting the right one can be challenging. This guide provides a comprehensive breakdown of band saw classifications, features, and key purchasing considerations.

| Type | Orientation | Best For | Key Advantage |

|---|---|---|---|

| Vertical Band Saw | Vertical | Curved/complex cuts | Maximum flexibility |

| Horizontal Band Saw | Horizontal | Straight cuts in bulk | High production speed |

| Dual-Column Saw | Horizontal | Heavy-duty cutting | Extreme stability |

| Type | Operation Mode | Production Scale | Price Range |

|---|---|---|---|

| Manual | Fully manual | Small batches | $1,500-$7,000 |

| Semi-Automatic | Partial automation | Medium batches | $7,000-$15,000 |

| CNC | Fully programmable | Mass production | $15,000+ |

| Type | Blade Characteristics | Typical Applications | Key Industries |

|---|---|---|---|

| Metal-Cutting | Fine-tooth, coolant | Steel, aluminum | Manufacturing |

| Wood-Cutting | Wide blade, fast cut | Lumber, plywood | Carpentry |

| Multi-Material | Interchangeable blades | Mixed materials | Repair shops |

| Parameter | Importance | Selection Tips |

|---|---|---|

| Cutting capacity | Determines max workpiece size | Choose 20% larger than current needs |

| Blade type | Affects cut quality | Bi-metal for metal, carbon for wood |

| Motor power | Impacts performance | 3HP minimum for industrial use |

| Automation | Affects labor costs | ROI calculation recommended |

| Budget Range | Recommended Type | Expected Usage Frequency |

|---|---|---|

| Under $7,000 | Manual horizontal | Occasional (≤10 hrs/week) |

| $7,000-$15,000 | Semi-automatic | Regular (20-40 hrs/week) |

| $15,000+ | CNC or dual-column | Continuous (50+ hrs/week) |

Cutting Capacity :

Cutting Capacity :