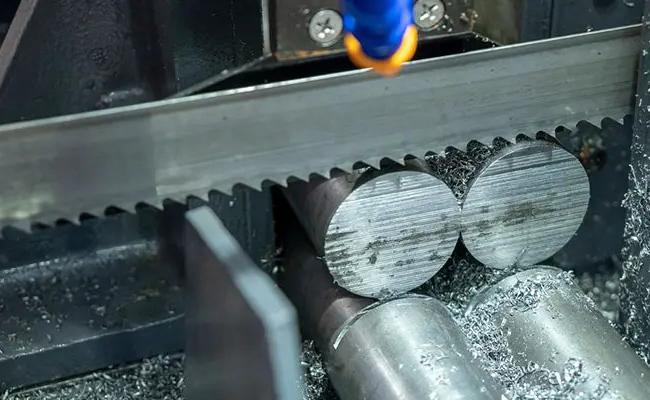

BS-1018T Metal Cutting Bandsaw

Cutting Capacity :

Circular saw machine manufacturers are professional companies that focus on the research and development, manufacturing and sales of circular saw machine equipment. Their core business revolves around the cutting needs in the fields of wood, metal, plastic and other material processing. As an important link in the industrial manufacturing system, such companies provide fast and accurate cutting solutions for downstream industries by integrating technology, processes and supply chain resources.

Product functions cover cutting needs in multiple scenarios:

The core products of circular saw machine manufacturers include woodworking circular saws, metal circular saws, precision panel saws, etc., which can meet the processing needs of different industries. For example, woodworking circular saws are used for panel slitting in furniture manufacturing, while metal circular saws are suitable for batch cutting of automotive parts and building profiles. The product optimizes the saw blade speed, feed speed and cutting angle to achieve fast material cutting and fine processing, and is equipped with modules such as automatic feeding and dust removal systems to improve operational safety and environmental protection.

Technical capabilities drive equipment performance upgrades:

Circular saw machine manufacturers need to have multi-disciplinary technology integration capabilities, covering mechanical design, material science, automation control and other fields. For example, by developing a high-rigidity bed structure to reduce vibration and improve cutting accuracy; using a servo motor drive system to achieve variable-speed cutting to adapt to different material hardnesses; developing an intelligent control system that integrates cutting parameter memory and fault diagnosis functions to reduce the need for manual intervention. In addition, some manufacturers also provide customized services for special needs, such as designing special-shaped cutting tracks or integrating robot loading and unloading systems.

Service support builds a full life cycle guarantee:

In addition to hardware production, circular saw machine manufacturers need to provide a complete service system from pre-sales consultation to after-sales maintenance. In the pre-sales stage, the technical team analyzes user needs and recommends suitable models; during the sale, equipment installation and commissioning, and operation training are provided; after the sale, a rapid response mechanism is established to shorten downtime through spare parts library coverage and remote diagnosis platforms. Some companies also provide value-added services such as saw blade grinding and process optimization to help users reduce comprehensive use costs.

Through continuous technological innovation and service deepening, circular saw machine manufacturers have become an important force in promoting the automation upgrade of the material processing industry. Its value is not only reflected in equipment supply, but also in helping users improve production efficiency and ensure product quality through customized solutions, and then achieve coordinated development of the industrial chain.

Cutting Capacity :

Cutting Capacity :