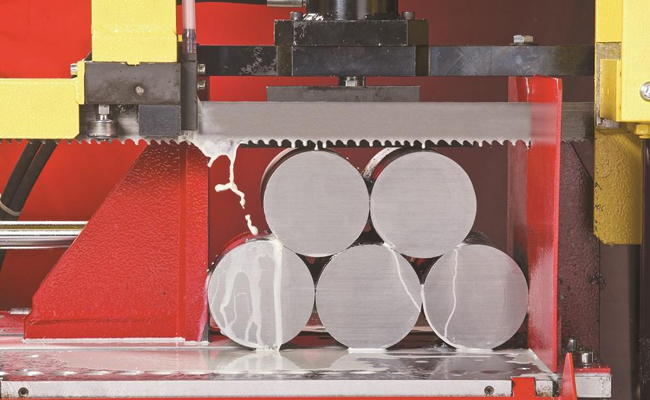

BS-460GB Horizontal Band Saw

Cutting Capacity :

Choosing the right band saw blade is crucial to the efficiency, accuracy and cost of sawing steel. The following are the key factors and steps to choose a band saw blade:

1. Determine the characteristics of the material being cut

Material type: ordinary carbon steel, alloy steel, stainless steel, tool steel, etc. Different materials have different hardnesses and need to match the corresponding saw blades.

Material hardness: measured with a hardness tester (such as HRC, HB value). The higher the hardness, the more wear-resistant and impact-resistant saw blades need to be selected.

Material shape and size: solid round steel, square steel, pipe or special-shaped material? Thick-walled materials require wider saw blades to enhance stability.

2. Choose the tooth shape of the band saw blade

Tooth pitch (TPI, number of teeth per inch):

Coarse teeth (low TPI, such as 2/3, 3/4): suitable for cutting thick materials (>50mm) or soft steel, large chip space and high efficiency.

Fine teeth (high TPI, such as 10/14, 14/18): suitable for thin-walled pipes (<10mm) or hard steel, reducing the risk of tooth collapse.

Variable teeth (such as 3/4, 6/10): reduce vibration and have strong versatility.

Tooth type:

Standard teeth: general cutting, suitable for most steels.

Hook teeth (large rake angle): cutting soft steel or aluminum, more aggressive cutting.

Impact-resistant teeth (negative rake angle): suitable for high-hardness materials (such as hardened steel, stainless steel).

3. Choose saw blade material and coating

Material:

Carbon steel saw blade: economical, suitable for soft steel or low-frequency cutting.

Bimetal saw blade (M42 high-speed steel teeth + spring steel back): most commonly used, taking into account wear resistance and toughness, suitable for alloy steel and stainless steel.

Carbide saw blade: used to cut high-hardness materials (such as titanium alloy, hardened steel), long life but high cost.

Coating:

Titanium nitride (TiN): Reduce friction, extend life, suitable for stainless steel.

Cobalt coating: Enhance heat resistance, suitable for high-speed cutting.

4. Saw blade width and thickness

Width:

Narrow saw blade (13-19mm): Suitable for small radius curve cutting or thin materials.

Wide saw blade (27-34mm): Suitable for straight-line cutting of thick materials, better stability.

Thickness: Thicker saw blades (such as 0.9mm) have high tensile strength but poor flexibility; thin saw blades (such as 0.6mm) are suitable for fine cutting.

5. Cutting parameter matching

Cutting speed (m/min):

Carbon steel: 20-60 m/min; Stainless steel: 10-30 m/min; Hard alloy requires lower speed.

Feed pressure: The harder the material, the smaller the feed pressure needs to be to avoid tooth collapse.

Coolant: It is recommended to use cutting fluid when cutting stainless steel or high-hardness materials to reduce thermal wear.

6. Brand and cost performance

Economical: domestic bimetallic saw blades (such as Taijia and Hengrui).

High performance: imported brands (such as German LENOX, American STARRETT, Japanese AMADA).

7. Common problems and solutions

Tooth collapse: Check whether the tooth pitch is too dense and the feed is too large.

Rapid wear: Confirm whether the saw blade material matches the material hardness, or check whether the cooling is sufficient.

Bevel cutting: It may be due to insufficient saw blade tension or wear of the guide block.

Example selection

Cutting 100mm thick mild steel: choose bimetallic saw blade, tooth pitch 3/4 TPI, width 27mm, no coating.

Cutting 6mm stainless steel pipe: choose bimetallic saw blade, tooth pitch 14/18 TPI, TiN coating, low speed + cutting fluid.

By comprehensively considering materials, tooth shape, saw blade material and cutting parameters, cutting efficiency can be significantly improved and costs can be reduced. It is recommended to test in small batches before purchasing in bulk.

Cutting Capacity :

Cutting Capacity :