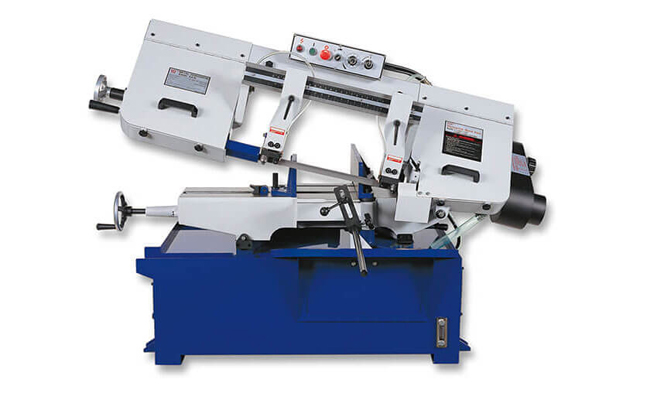

BS-315GH Horizontal Band Saw

Cutting Capacity :

The band saw is an essential piece of equipment in industries such as woodworking and metal cutting, and its performance directly impacts processing efficiency and product quality. However, prolonged use can lead to issues such as blade wear, loose components, and insufficient lubrication, which may reduce cutting precision or even cause equipment failure. Therefore, scientific maintenance methods are crucial. This article provides a detailed guide on band saw maintenance to help users extend equipment lifespan and ensure stable operation.

I. Daily Maintenance (After Each Use)

1. Cleaning the Equipment

During operation, band saws generate a large amount of sawdust, metal chips, or grease. If not cleaned promptly, these can clog moving parts and affect precision.

Blade and Wheels: Use a brush or compressed air to remove debris between the teeth to prevent buildup that could hinder cutting.

Worktable and Guides: Wipe clean to prevent scratches or chips from jamming the sliding blocks.

Machine Interior: Regularly clean the motor vents to prevent dust accumulation and overheating.

2. Inspecting the Blade Condition

The blade is the core component of a band saw, and its condition directly affects cutting quality.

Tooth Inspection: Check for broken, dull, or cracked teeth. Replace or sharpen if necessary.

Tension Adjustment: If the saw will be idle for an extended period, release blade tension to prevent wheel deformation or fatigue fractures.

3. Lubricating Key Components

Proper lubrication reduces friction and extends component life.

Guides and Sliding Blocks: Apply light lubricating oil (e.g., ISO VG32) to ensure smooth movement.

Bearings and Gears: Regularly apply grease to prevent dry friction damage.

Note: Avoid excessive lubrication, as it may contaminate materials (e.g., wood absorbing oil can affect further processing).

4. Checking Safety Devices

Safety measures are critical when operating a band saw.

Protective Cover: Ensure it is secure to prevent debris from flying out.

Emergency Stop Button: Test for responsiveness to ensure immediate shutdown in emergencies.

Blade Guard: Adjust to the proper position to keep hands away from the blade during operation.

II. Periodic Maintenance (Weekly or Monthly)

1. Inspecting the Drive System

Belts and Chains: Check tension—too loose causes slipping, too tight increases motor load.

Motor and Bearings: Listen for unusual noises; replace bearings or adjust motor bolts if needed.

2. Aligning the Blade and Wheels

Wheel Alignment: Use a straightedge to check if both wheels are on the same plane—misalignment can cause blade drift.

Blade Guides: Adjust guide blocks to ensure smooth blade movement and minimize vibration.

3. Checking the Electrical System

Cables and Switches: Inspect for damage or poor contact to prevent short circuits or electrical leakage.

Motor Brushes (if applicable): Replace if severely worn to avoid insufficient motor power.

III. Long-Term Maintenance (Every 6 Months or Yearly)

1. Comprehensive Disassembly and Cleaning

Remove critical components such as wheels and bearings to clean accumulated dust and grease.

Check gearbox oil and replace if necessary (for heavy-duty industrial band saws).

2. Replacing Worn Parts

Blade: Even if no visible damage is present, replace after prolonged use to maintain sharp cutting.

Guides and Sliding Blocks: Replace if severely worn to prevent cutting deviations.

3. Professional Calibration

For high-precision cutting needs, annual professional servicing is recommended:

Wheel Dynamic Balancing Test (prevents vibration during high-speed operation).

CNC System Calibration (for automated band saws).

IV. Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Blade Drift | Misaligned wheels, worn guide blocks | Adjust wheel position, replace guide blocks |

| Rough Cuts | Dull teeth, excessive feed speed | Sharpen or replace blade, reduce feed speed |

| Unusual Noise | Worn bearings, loose belt | Replace bearings, adjust belt tension |

| Motor Overheating | Poor ventilation, excessive load | Clean vents, check if blade is too tight |

Maintaining a band saw is not complicated but requires consistent cleaning, regular inspections, and timely lubrication. Proper upkeep reduces failure rates, improves cutting precision, and lowers production costs. For industrial band saws under heavy use, a maintenance schedule should be implemented to ensure all steps are followed. Only through proper maintenance can the machine operate stably and perform optimally in the long run.

Cutting Capacity :

Cutting Capacity :