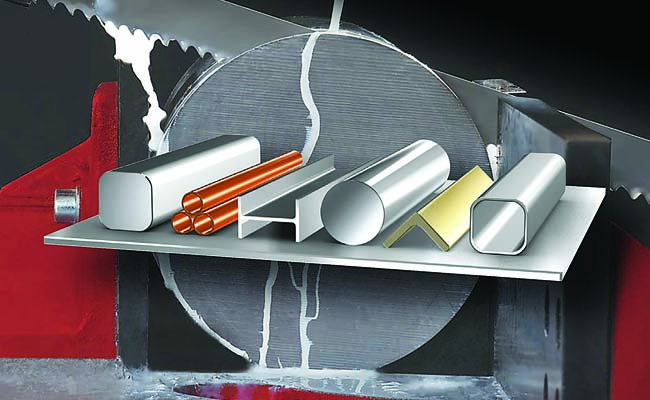

GZ4250 Fully Automatic Band Saw Machine

Cutting Capacity :

Setting the correct blade speed (SFPM – Surface Feet Per Minute) and feed rate for your metal-cutting bandsaw is crucial for achieving clean cuts, prolonging blade life, and maximizing efficiency. Here’s a guide for different materials:

1. Understanding Key Factors

Blade Speed (SFPM): How fast the blade moves (typically 50–350 SFPM for metal).

Feed Rate: How aggressively the blade is pushed into the material (controlled by downfeed pressure or manual feed).

Tooth Pitch (TPI): The number of teeth per inch (finer for thin materials, coarser for thick ones).

2. Recommended Blade Speed (SFPM) by Material

| Material | Blade Speed (SFPM) | Notes |

|---|---|---|

| Carbon Steel | 80–120 SFPM | Harder alloys require slower speeds. |

| Stainless Steel | 60–100 SFPM | Slower for high-hardness grades. |

| Aluminum | 200–350 SFPM | High speed, low feed pressure. |

| Brass/Bronze | 150–300 SFPM | Medium speed, moderate feed. |

| Copper | 200–350 SFPM | Similar to aluminum. |

| Titanium | 50–80 SFPM | Very slow to prevent work hardening. |

| Cast Iron | 80–120 SFPM | Coarse tooth blade recommended. |

| Tool Steel | 50–90 SFPM | Hardened steel needs slower speeds. |

3. Feed Rate Guidelines

Too Slow: Causes blade wear due to rubbing.

Too Fast: Leads to blade tooth stripping or breakage.

Optimal Feed: Should produce small, tightly curled chips (not dust or large chunks).

Feed Rate Adjustments:

Soft Metals (Aluminum, Copper): Higher feed rate (moderate pressure).

Hard Metals (Stainless, Tool Steel): Lower feed rate (gentle pressure).

Thin Materials: Reduce feed to prevent tooth stripping.

4. Blade Tooth Selection (TPI)

General Rule: At least 3–6 teeth in contact with the workpiece.

Thin Material (≤1/8″): 14–24 TPI (fine teeth).

Medium (1/8″–1/2″): 10–14 TPI.

Thick (>1/2″): 6–10 TPI (coarse teeth).

Very Thick (>4″): 3–6 TPI.

5. Additional Tips

Use Cutting Fluid: Extends blade life and improves cut quality (especially for steel, stainless, titanium).

Break In New Blades: Run at 50% speed/feed for the first few cuts to condition teeth.

Listen & Observe:

Squealing? → Speed too high or feed too light.

Blade Teeth Stripping? → Feed too heavy or TPI too low.

Manual vs. Hydraulic Feed: Adjust pressure based on material hardness.

6. Example Settings

| Material | Blade Speed (SFPM) | Feed Pressure | TPI (Example) |

|---|---|---|---|

| 1″ Mild Steel | 100 SFPM | Medium | 8–10 TPI |

| 1/4″ Aluminum | 300 SFPM | High | 10–14 TPI |

| 1/2″ Stainless | 80 SFPM | Low-Medium | 10–12 TPI |

| 2″ Titanium | 60 SFPM | Low | 6–8 TPI |

Cutting Capacity :

Cutting Capacity :