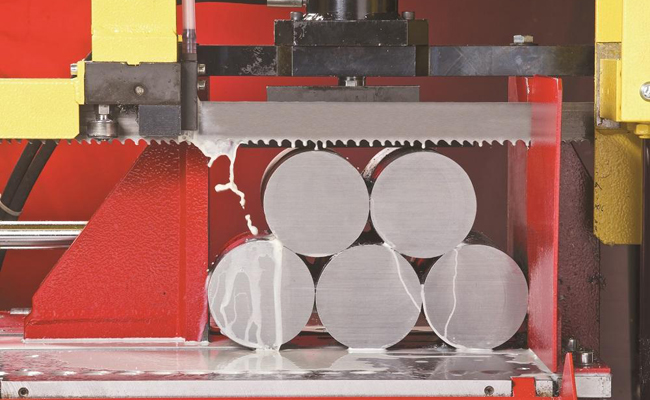

CL4370HB horizontal band saw for mold steel(Servo cylinder)

Cutting Capacity :

Fully automatic circular saw machine processing manufacturers are professional manufacturers focusing on the production, research and development and sales of automated circular saw cutting equipment. Their core business revolves around the precision cutting needs of metal, wood, plastic and other materials, providing fast and accurate processing solutions for the manufacturing industry. Through technological innovation and service deepening, they promote the transformation of traditional cutting processes to rapid and flexible, and become an important supporting force for the transformation and upgrading of the manufacturing industry.

Core business: equipment research and development and manufacturing

Fully automatic circular saw machine processing manufacturers integrate professional technologies in the fields of mechanical design, automatic control, materials science, etc. to develop circular saw cutting equipment suitable for different industries. For example, for metal processing scenarios, the equipment needs to have high speed and high torque characteristics to meet the cutting needs of hard materials such as stainless steel and aluminum alloy; in the field of wood processing, it is necessary to optimize the dustproof structure and saw blade cooling system to ensure processing accuracy and equipment life. In addition, the manufacturer will provide customized equipment design services based on customer process requirements, such as the development of fixtures for special-shaped workpieces and the integration of multi-axis linkage control systems.

Technology empowerment: automation and intelligent upgrade

Fully automatic circular saw machine processing manufacturers have introduced PLC control systems, servo drive technology and industrial Internet of Things modules to promote the development of circular saw machines in the direction of intelligence. For example, the equipment can automatically identify the material thickness and adjust the cutting parameters to achieve unmanned continuous operation; the visual inspection system can monitor the cutting quality in real time to avoid processing errors caused by saw blade wear. Some manufacturers also provide Industry 4.0 solutions, which can realize remote operation and maintenance, production data traceability and other functions through equipment networking, helping enterprises to optimize production processes.

Service guarantee: full life cycle support

Fully automatic circular saw machine processing manufacturers not only provide equipment sales, but also focus on building a one-stop service system covering installation and commissioning, operation training, and after-sales maintenance. For example, during the equipment delivery stage, technicians will assist customers in completing the commissioning of tooling fixtures and conduct programming and safety specification training for operators; during the equipment operation stage, regular inspections and rapid supply of spare parts can be used to reduce customer downtime risks. In response to the needs of upgrading old equipment, manufacturers can also provide value-added services such as CNC system transformation and energy-saving optimization.

Cutting Capacity :

Cutting Capacity :