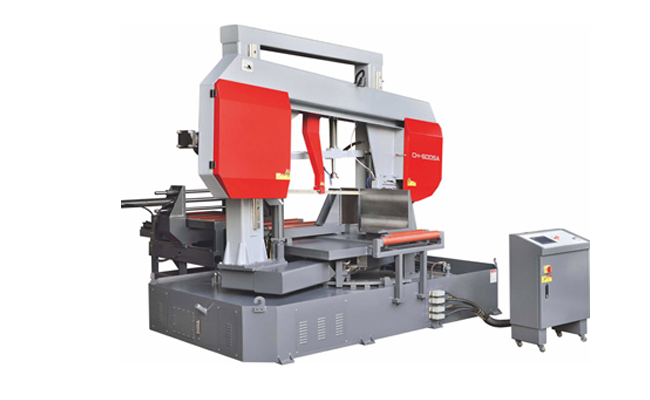

BS-1018B Metal Cutting Bandsaw

Cutting Capacity :

Metal band saw is a simple yet incredibly efficient and versatile cutting tool.

Here’s a breakdown of how it works, from the basic principle to the key components and the different types you’ll encounter.

The Core Principle: A Continuous, Toothy Loop

Imagine taking a metal ruler, welding the ends together to form a loop, and then running it around two large wheels. Now, replace the ruler with a flexible, hardened steel blade that has sharp teeth cut into one edge. That’s the fundamental idea of a band saw.

The blade is a continuous loop that moves in one constant direction, allowing each tooth to act like a tiny, precision chisel, removing a small chip of metal with every pass.

To understand how it works, let’s look at its main parts:

The Blade: This is the heart of the saw.

Material: Typically made from high-speed steel (HSS), bi-metal (a flexible HSS tooth edge welded to a flexible spring-steel body), or carbide-tipped for the toughest materials.

Teeth: The number, size, and shape of the teeth (the “tooth pitch”) are critical. More teeth per inch (TPI) give a smoother cut on thinner materials, while fewer TPI are better for thick stock and softer metals like aluminum.

Flexibility: The blade must be flexible enough to go around the wheels but rigid enough to resist the cutting forces.

The Wheels: Two large, heavy wheels (one driven, one idler) guide and propel the blade in a continuous loop. The driven wheel is connected to the motor.

The Motor: Provides the power to turn the wheels and move the blade. The speed is often variable, as cutting different metals (e.g., steel vs. aluminum) requires different blade speeds.

The Frame: A heavy, rigid structure (often C-shaped) that supports all the components and resists the forces of cutting.

The Blade Guides and Bearings: These are crucial for accuracy and blade life. They are located above and below the workpiece and prevent the blade from twisting, deflecting, or being pushed off the wheels. They ensure the cut is straight and true.

The Vise or Clamp: A sturdy clamping mechanism that holds the workpiece securely in place. A loose workpiece is dangerous and will ruin the blade.

The Hydraulic or Pneumatic Feed System (on many industrial models): This applies a controlled, downward force to feed the blade into the workpiece. This is often adjustable—too much force will break the blade, too little will cause it to rub and dull prematurely.

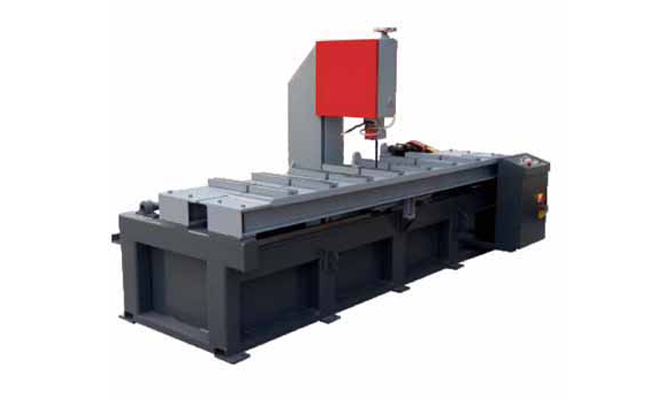

Metal band saws come in two primary configurations, which differ in how the cutting action is applied:

This is the most common type for cutting stock to length (e.g., cutting a long bar of steel into smaller pieces).

How it Works: The blade runs vertically between two wheels on a horizontal arm. The workpiece is clamped in a stationary vise. The entire cutting head (the arm, wheels, and motor) is pivoted downward into the fixed workpiece, either by gravity or a controlled hydraulic cylinder.

The Process:

The operator measures and clamps the material in the vise.

The saw is started, and the cutting head slowly descends.

The blade cuts through the material until the head reaches a set limit switch, automatically shutting off.

Key Feature: Often called a “cut-off saw,” it’s designed for high-volume, repetitive cutting of bar stock, pipe, and tubing. It can often run unattended once the cut has started.

This type is more versatile for contour cutting, shaping, and intricate work.

How it Works: The blade runs vertically on two wheels housed in a tall, vertical column. The workpiece is placed on a horizontal table, and the operator manually feeds the material into the stationary blade.

The Process:

The blade is threaded through a starter hole in the workpiece if doing an internal cut.

The operator turns on the saw and carefully pushes the material against the blade, steering it to follow a layout line or template.

Key Feature: Its primary advantage is the ability to make curved and irregular cuts, not just straight ones. It’s like a jigsaw for metal, but with much greater power and precision.

Whether horizontal or vertical, the actual cutting mechanics are the same:

Chip Formation: As each tooth enters the workpiece, its sharp edge digs in and removes a small, curled piece of metal called a “chip.”

Chip Removal: The gullet (the space between the teeth) is designed to carry this chip out of the cut as the blade exits the workpiece.

Heat Dissipation: The continuous movement of the blade helps to draw heat away from the cutting area. Using cutting fluid (coolant) is also common to further reduce heat, lubricate the cut, and extend blade life.

Continuous Cutting: Because the blade is a loop, the cutting action is constant and smooth, unlike the reciprocating action of a hacksaw which cuts only on the forward stroke.

Efficiency: The continuous cutting motion is very fast and requires less operator effort.

Versatility: Can cut a wide range of shapes, sizes, and types of metal.

Accuracy: Produces straight, clean, and precise cuts with a good surface finish.

Minimal Material Waste: The blade is thin (the “kerf” is small), so very little material is turned into chips, saving money on expensive metals.

Safety: When used correctly, it is generally safer than angle grinders or circular saws, as the cutting force pulls the workpiece down onto the table (in a vertical saw) and there are no flying abrasive fragments.

In summary, a metal band saw works by using a continuous, toothed metal band driven by two wheels to make a controlled, efficient, and versatile cut through metal, with the specific setup (horizontal or vertical) determining its primary application.

Cutting Capacity :

Cutting Capacity :