BS-128DR Metal Cutting Band saw

Cutting Capacity :

In today’s fast-paced industrial world, efficiency and precision are non-negotiable. For metal fabricators, manufacturers, and workshops, investing in a full-automatic saw cutting machine is a game-changer. These machines deliver unmatched accuracy, speed, and consistency, making them indispensable in modern metal processing.

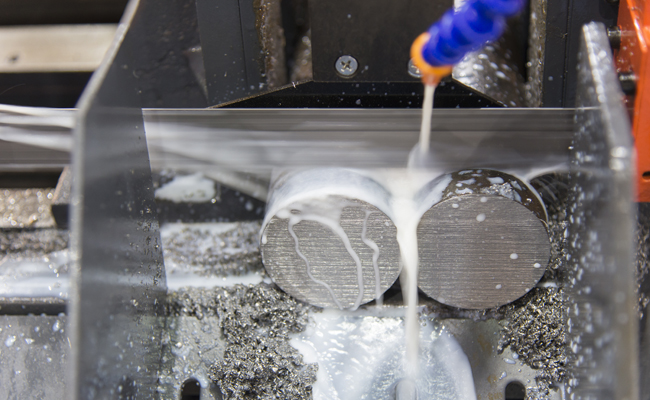

The band saw machine cutting the steel rod with the coolant

But what exactly makes these machines so valuable ? Let’s break it down.

What Is a Full-Automatic Saw Cutting Machine?

A full-automatic saw cutting machine is a high-tech cutting solution designed for metal processing. Unlike manual or semi-automatic saws, these machines operate with minimal human intervention. They are programmed to handle feeding, clamping, cutting, and even sorting—delivering flawless cuts every time.

Key Features of a Full-Automatic Saw Cutting Machine

Precision Cutting

Laser-guided or CNC-controlled systems ensure exact cuts with tolerances as tight as ±0.1mm.

Ideal for high-volume production where consistency is critical.

High-Speed Operation

Advanced blade technology and motor systems allow for rapid cutting without sacrificing accuracy.

Some models can process hundreds of cuts per hour.

Automated Material Handling

Built-in feeders and conveyors load and unload materials automatically.

Reduces labor costs and minimizes human error.

Versatility

Cuts various metals, including steel, aluminum, copper, and alloys.

Adjustable settings for different thicknesses and shapes (round, square, or rectangular bars).

Durability & Low Maintenance

Constructed with heavy-duty materials to withstand continuous operation.

Self-lubricating systems and easy-access parts simplify maintenance.

Why Should You Upgrade to a Full-Automatic Saw Cutting Machine?

1. Increased Productivity

Manual cutting is slow and labor-intensive. A full-automatic machine works non-stop, drastically boosting output.

2. Cost Efficiency

Though the initial investment is higher, the long-term savings on labor, material waste, and downtime make it worthwhile.

3. Superior Cut Quality

No more jagged edges or uneven cuts. Automated saws produce clean, burr-free finishes, reducing the need for secondary processing.

4. Enhanced Safety

Operators are less exposed to blades and moving parts, reducing workplace accidents.

5. Smart Technology Integration

Many modern models come with IoT capabilities, allowing remote monitoring, predictive maintenance, and real-time adjustments.

Choosing the Right Machine for Your Needs

Not all automatic saw cutting machines are the same. Consider these factors before purchasing:

Material Type & Thickness – Ensure the machine can handle your specific metal grades and dimensions.

Cutting Capacity – Check maximum bar diameter and length compatibility.

Blade Type – Bandsaws, circular saws, and cold saws each have pros and cons.

Automation Level – Some machines offer partial automation, while others are fully autonomous.

Brand & Support – Opt for reputable manufacturers with strong after-sales service.

The metal fabrication industry is evolving, and those who embrace automation gain a competitive edge. A full-automatic saw cutting machine is not just a tool—it’s a productivity powerhouse that enhances precision, reduces waste, and maximizes profits.

If you’re still relying on outdated cutting methods, now is the time to upgrade. The future of metal processing is here—are you ready for it?

Looking for the best automatic saw cutting machine? Contact industry-leading suppliers today and request a demo to see the difference firsthand!

Cutting Capacity :

Cutting Capacity :