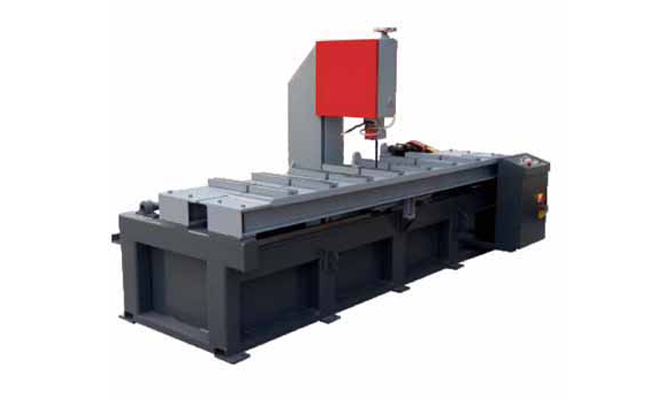

BS-1018RH Metal Cutting Bandsaw

Cutting Capacity :

Stainless steel is a cornerstone of modern industry, prized for its corrosion resistance, strength, and aesthetic appeal. However, these very properties—particularly its work-hardening nature and toughness—make it a challenging material to cut efficiently. Using the wrong saw or the wrong technique can lead to ruined blades, poor cut quality, work-hardened surfaces, and even damage to the machine.

The bandsaw is the undisputed champion for cutting stainless steel in an industrial setting. Its continuous, linear cutting action distributes heat and wear evenly across a long blade, resulting in faster cuts, longer blade life, and less material waste compared to circular saws or abrasive chop saws. But not all bandsaws are created equal. Selecting the best bandsaw machine for cutting stainless steel requires a careful analysis of your production needs, the specific grade of stainless steel, and the features that ensure a clean, precise, and cost-effective cut.

This ultimate guide will walk you through everything you need to know to make an informed decision and invest in a machine that will boost your productivity for years to come.

The first step in choosing the right bandsaw is understanding the fundamental types available. Each is suited to different operational scales and cut requirements.

1. Horizontal Bandsaws

This is the most common type of saw for cutting bar stock, tubing, and structural shapes to length. The blade moves in a horizontal plane, and the cutting head (or the material) feeds down into the workpiece.

Vertical Bandsaw: While excellent for contour cutting and intricate shapes, they are generally less common for high-volume production cutting of stainless steel stock. They require manual feeding, which can lead to inconsistency and operator fatigue.

Horizontal Bandsaw: The workhorse for cut-to-length applications. Ideal for chopping stainless steel rounds, squares, and tubes into smaller blanks for machining or fabrication.

2. Vertical Bandsaws

In a vertical bandsaw, the blade runs vertically, and the workpiece is pushed manually or with a feed table into the blade. They are incredibly versatile.

Best For: Contour cutting, notching, and intricate shapes in stainless steel plate or sheet. They are not typically used for high-volume production cutting of solid bar stock.

Consideration: Operator skill is a significant factor in achieving straight and accurate cuts on a manual vertical bandsaw.

3. CNC Bandsaws

For the highest level of precision, repeatability, and automation, CNC (Computer Numerical Control) bandsaws are the pinnacle. They can be either horizontal or vertical in orientation.

Horizontal CNC Bandsaws: Automate the entire cutting process. They can bundle-cut multiple pieces, feature automatic material indexing, and integrate with robotics for a fully automated workflow. This is the best choice for high-volume production environments.

Vertical CNC Bandsaws (CNC Plate Saws): Used for cutting complex shapes from large plates of stainless steel. They are programmed to follow a CAD drawing path with extreme accuracy.

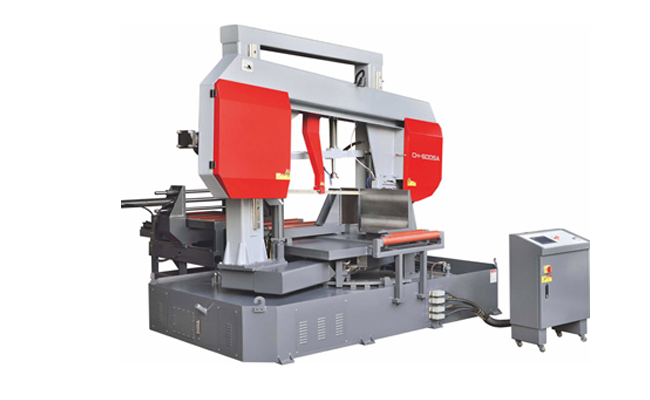

4. Dual Column (Column-Type) Bandsaws

A subtype of horizontal bandsaws, dual-column models offer superior rigidity and stability. The cutting head travels on two large vertical columns, minimizing deflection during heavy cuts.

Best For: Cutting large-diameter solid rounds or thick-walled sections of stainless steel where blade guidance and machine stability are critical to prevent blade wander and ensure a square cut.

Choosing the bandsaw is only half the battle. The blade and its operating parameters are what actually do the work. Getting this wrong will negate the benefits of even the best machine.

The Blade: Your Most Important Consumable

Blade Material: Bi-Metal is Mandatory.

For cutting stainless steel, a bi-metal blade is the absolute minimum requirement. These blades combine a flexible, shock-resistant backer (usually a spring steel) with a high-speed steel (HSS) cutting edge welded to the teeth. This gives you the toughness to withstand the stresses of cutting hard materials and the heat resistance to prevent premature wear. Carbide-tipped blades are the premium choice for the most abrasive or hardest stainless steels (like 400 series) and for the highest production rates, offering significantly longer life but at a much higher initial cost.

Tooth Geometry: The Shape of the Cut.

Regular Tooth: A general-purpose tooth shape with a 0° rake angle. Good for a mix of solids and structural shapes.

Hook Tooth: Has a deeper gullet and a positive 10° rake angle. This is highly recommended for stainless steel as it provides a more aggressive, free-cutting action that helps pull the chip out of the cut, reducing heat buildup.

Variable Pitch (VP): The tooth spacing varies along the blade. This is critical for cutting stainless steel profiles (like tubes and pipes). Variable pitch disrupts the harmonic vibration that can occur when all teeth hit the material at the same frequency, leading to a smoother, quieter cut and dramatically extended blade life.

Tooth Set: The Width of the Kerf.

The pattern in which teeth are bent left and right. A Raker Set (one tooth left, one right, one unset) is standard for cutting stainless steel solids. A Wavy Set (groups of teeth bent in a wave pattern) is better for thin-walled tubes and profiles as it provides more support and prevents tooth stripping.

The Cut Parameters: Science in Action

Blade Speed (SFPM – Surface Feet Per Minute): Stainless steel must be cut at much slower speeds than mild steel. Running too fast generates excessive heat, which work-hardens the material and destroys the blade’s cutting edge. A general range for bi-metal blades cutting stainless is 80 – 150 SFPM, with softer grades (e.g., 304) at the higher end and harder grades (e.g., 316, 410) at the lower end.

Feed Pressure/Rate: This is the force with which the blade is pushed into the material. Too little pressure causes the blade to rub and glaze the material, work-hardening it. Too much pressure can overstress and strip teeth. The goal is to achieve a tight, curled chip. A silver-colored, powdery chip indicates too little feed; a blue, burned chip indicates too much feed or speed. A thick, tightly curled silver chip is ideal.

Coolant: Non-Negotiable. Using a high-quality, sulfur-based cutting fluid or coolant is essential. It reduces heat, lubricates the cut, flushes chips from the gullets, and prolongs blade life exponentially. Flood coolant is the standard for industrial machines.

| Feature | Horizontal Bandsaw | Vertical Bandsaw | CNC Horizontal Bandsaw |

|---|---|---|---|

| Primary Use | Cut-to-length of bar stock, tube, structurals | Contour cutting, shaping, notching | High-volume production cut-off |

| Best for Stainless Steel | Solid rounds, squares, heavy-wall tube | Plate, sheet, thin-wall tube | All profiles, especially large bundles |

| Automation Level | Manual to Semi-Automatic | Manual | Fully Automatic (with auto feed & indexing) |

| Precision/Repeatability | Good to Very Good | Fair (operator dependent) | Excellent |

| Operator Skill Required | Moderate | High | Low (for operation) / High (for programming) |

| Typical Blade Width | 1″ to 2″ (25mm to 50mm) | 1/4″ to 1″ (6mm to 25mm) | 1.25″ to 2″ (32mm to 50mm) |

| Relative Cost | $$ | $ | $$$$ |

| Key Advantage | Versatility, cost-effectiveness for most shops | Unmatched for complex shapes | Unbeatable productivity & consistency |

A well-maintained bandsaw is a precise and profitable bandsaw. Neglect leads to downtime and costly repairs.

Daily Maintenance:

Clean the Chip Pan: Remove accumulated chips and sludge from the base of the machine.

Check Coolant Level: Top up the coolant reservoir as needed. Check for proper flow from all nozzles.

Inspect the Blade: Look for signs of wear, cracks, or damaged teeth before starting.

Wipe Down Guides & Ways: Clean the blade guide components and the machine’s linear ways to prevent abrasive damage.

Weekly/Bi-Weekly Maintenance:

Check Coolant Concentration: Use a refractometer to ensure the coolant-to-water ratio is correct. Weak coolant leads to rust and poor lubrication; too-strong coolant can cause foaming and skin irritation.

Lubricate Moving Parts: Grease the pivot points, lead screws, and other moving parts as per the manufacturer’s manual.

Inspect Drive Belts: Check for tension and signs of wear or cracking.

Monthly/Quarterly Maintenance:

Replace Coolant: Fully drain, clean the tank, and replace with fresh coolant to prevent bacterial growth and rancidity.

Check Wheel Brush: Ensure the blade wheel cleaning brush is effective at removing debris from the tires.

Inspect Hydraulic System: Check for leaks and check hydraulic fluid level and condition.

Verify Alignment: Check the blade for tracking and the machine for squareness to ensure cuts are 90 degrees.

Safety must always be the top priority. A bandsaw is a powerful tool that demands respect.

Personal Protective Equipment (PPE) is Mandatory:

Safety Glasses or Face Shield: Protect from flying chips and coolant splash.

Hearing Protection: Bandsaws can be loud, especially in an enclosed shop.

Gloves: Wear heavy-duty gloves when handling raw material. NEVER wear gloves while operating the machine near the moving blade, as they can get caught.

Sturdy Boots & No Loose Clothing.

Machine Operation Safety:

Read the Manual: Understand all the functions and safety features of your specific machine.

Ensure Guards are in Place: Never operate a bandsaw with the blade guards removed.

Secure the Workpiece: Use the machine’s vise or clamps to firmly hold the material. A shifting workpiece can bind the blade and cause it to break or kick back.

Let the Machine Stop Naturally: Never force or brake the wheels to stop the blade quickly.

Keep Hands Clear: Keep your hands away from the blade path at all times. Use a push stick when feeding material on a vertical bandsaw.

Disconnect Power: Always lock out/tag out the power source before performing any blade changes or maintenance.

Investing in the best bandsaw machine for cutting stainless steel is an investment in your shop’s future capability and profitability. The right machine, paired with the correct blade and optimal cutting parameters, transforms a difficult task into a smooth, repeatable, and efficient process.

By understanding the different types of bandsaws, the critical role of blade selection, and the non-negotiable practices of maintenance and safety, you are equipped to make a choice that will deliver clean, precise cuts, minimize material waste, and maximize your return on investment. Don’t just buy a saw; invest in a solution that empowers your workshop to handle stainless steel with confidence and skill.

Cutting Capacity :

Cutting Capacity :