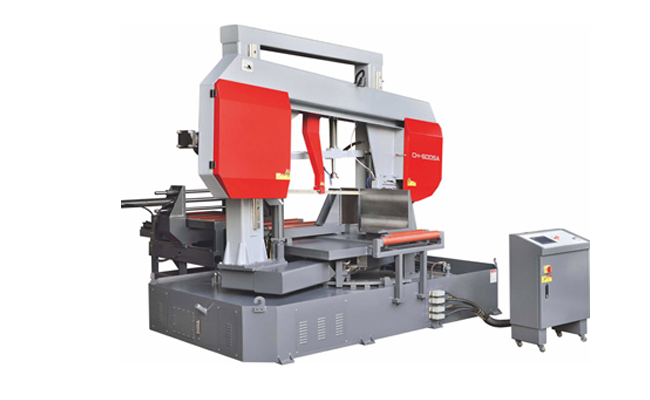

BS-1018RH Metal Cutting Bandsaw

Cutting Capacity :

A Fully Automatic Double Column Band Saw Machine is an industrial-grade cutting system designed for high-volume, high-precision, and unattended cutting of large metal stock. It represents the pinnacle of bandsaw technology, integrating robust mechanical design with sophisticated computer numerical control (CNC). The defining feature is its double-column (or twin-column) structure, which provides exceptional rigidity and stability for handling heavy and large-diameter material, such as solid billets, beams, and bundles of bar stock. “Fully automatic” signifies that the entire cutting process—from material feeding and clamping to cutting, indexing, and part ejection—is automated and managed by a programmable logic controller (PLC) or CNC system, requiring minimal operator intervention.

2.1 Double Column Frame: Constructed from high-grade cast iron or welded steel, the twin columns ensure minimal vibration and deflection during cutting, which is critical for achieving perfect squareness and dimensional accuracy, especially on large cross-sections.

2.2 CNC Control System: The brain of the machine. It allows operators to program cut lengths, quantities, and feeding sequences. Advanced systems feature touch-screen interfaces, data storage for hundreds of programs, and diagnostics.

2.3 Automatic Material Feeding: Typically consists of a heavy-duty vice mounted on a powered feed carriage. The system automatically moves the stock to the pre-programmed cut length position with high repeatability.

2.4 Integrated Hydraulic or Servo Clamping: Powerful clamps secure the material firmly during the cutting cycle to prevent movement that could cause blade damage or inaccurate cuts.

2.5 Semi-Submerged Cutting Head: The cutting head, which holds the blade wheels and guides, lowers into a reservoir of coolant during operation. This design ensures optimal blade cooling, lubrication, and chip removal, significantly extending blade life.

2.6 Automatic Chip Conveyor: An integrated conveyor system continuously removes swarf (metal chips) from the coolant tank, maintaining a clean cutting environment and reducing maintenance downtime.

The operational workflow of a fully automatic double column bandsaw is a continuous cycle:

Loading: An operator or a robotic arm loads long stock onto the machine’s infeed rack.

Feeding: The automatic vice opens, moves forward to the programmed “feed length,” closes to grip the material, and pulls it into the cutting position.

Clamping: The main hydraulic clamps (front and rear) secure the material firmly in place. The vice releases its grip to return to its start position without moving the stock.

Cutting: The saw arm, with the continuous band blade, descends automatically. The cutting speed and feed force are controlled hydraulically or via servo motors for optimal performance.

Return & Indexing: Upon completing the cut, the saw arm retracts. The finished part is ejected onto an outfeed table or conveyor. The vice then repeats the cycle, feeding the next length of material, and the process continues unattended until the entire bar is processed or the programmed quantity is reached.

4.1 Unmatched Productivity: Capable of 24/7 unmanned operation, drastically increasing throughput and reducing labor costs per part.

4.2 Superior Accuracy and Repeatability: The rigid double-column design and precision servo controls ensure consistent cut length tolerances within ±0.004 inches (±0.1 mm) and exceptional perpendicularity.

4.3 Enhanced Blade Life: The semi-submerged cutting action and automated feed controls provide constant cooling and consistent cutting pressure, reducing premature blade wear.

4.4 Material and Labor Savings: Optimized nesting and cutting programs minimize kerf loss (material wasted by the cut). Automation reduces the need for skilled labor to monitor each cut.

4.5 Improved Safety: The fully enclosed cutting process, with interlocked doors, protects operators from moving parts, chips, and coolant, creating a much safer work environment.

5.1 High Initial Investment: These machines represent a significant capital expenditure compared to manual or semi-automatic saws.

5.2 Floor Space and Infrastructure: They are large, heavy machines that require a substantial foundation, high-power electrical connections, and compressed air.

5.3 Complexity: Maintenance and troubleshooting require trained personnel familiar with hydraulic, pneumatic, and CNC systems.

5.4 Programming Time: For very small, one-off batches, the time to program and set up the machine may be less efficient than using a manual saw.

These machines are the workhorses of industries that require mass production of metal parts from long stock.

Automotive: Cutting axle shafts, drive shafts, and other chassis components.

Aerospace: Processing high-strength alloy billets and titanium bars for forging and machining blanks.

Oil & Gas: Cutting large-diameter pipes, flanges, and valve bodies.

Manufacturing: Producing precise blanks for CNC machining centers in high volumes.

Structural Fabrication: Cutting large I-beams, square and rectangular tubing to length.

The following table outlines typical specifications for various models of Fully Automatic Double Column Band Saws, illustrating their capacity and capabilities.

Table: Typical Specifications for Fully Automatic Double Column Band Saws

| Feature / Model Category | Standard Duty | Heavy Duty | Extra Heavy Duty |

|---|---|---|---|

| Max. Cutting Capacity (Round) | 16″ – 20″ (400 – 500 mm) | 24″ – 32″ (600 – 800 mm) | 36″ – 45″ (900 – 1140 mm) |

| Max. Cutting Capacity (Rectangular) | 20″ x 20″ (500 x 500 mm) | 32″ x 32″ (800 x 800 mm) | 40″ x 40″ (1000 x 1000 mm) |

| Blade Size (Length x Width) | ~ 20′ x 1.5″ (6m x 38mm) | ~ 26′ x 2″ (8m x 50mm) | ~ 34′ x 2.5″ (10.5m x 65mm) |

| Blade Speed (FPM / m/min) | 50-300 FPM (15-90 m/min) | 40-280 FPM (12-85 m/min) | 30-250 FPM (9-75 m/min) |

| Main Motor Power | 10-15 HP (7.5-11 kW) | 15-25 HP (11-18.5 kW) | 25-40 HP (18.5-30 kW) |

| Control System | PLC with HMI | Advanced CNC with Servo Drives | Advanced CNC with Servo Drives |

| Typical Automation | Auto Feed, Clamp, Cutting | + Barcode Reader, Auto Lubrication | + Robotic Load/Unload Integration |

| Estimated Throughput (Cuts/Hr on 4″ Steel)* | 60 – 90 | 50 – 80 | 40 – 70 |

*Throughput is highly dependent on material type and hardness. Values are for comparative purposes only.

8.1 Primary Material: The hardness and abrasiveness of the materials you cut (e.g., steel, aluminum, titanium, superalloys) will determine the required machine rigidity, motor power, and blade specifications.

8.2 Production Volume and Shift Patterns: Justify the investment based on the required output. These machines are ideal for multi-shift, high-volume production.

8.3 Required Accuracy: If your downstream processes require precise blank lengths to minimize machining time, the accuracy of a double column saw is essential.

8.4 Future-Proofing: Consider the potential for integration with factory automation systems (MES, ERP), robotics, and bar feeding systems.

8.5 Supplier Support: Ensure the manufacturer or distributor offers comprehensive technical support, training, and a reliable supply of spare parts.

The Fully Automatic Double Column Band Saw Machine is not merely a cutting tool but a complete production cell. It is the optimal solution for modern manufacturing facilities aiming to maximize efficiency, consistency, and safety in their cutoff operations. While the initial investment is substantial, the return on investment—through dramatic gains in productivity, material yield, and reduced operational costs—makes it an indispensable asset for any serious metalworking operation focused on large-scale production.

Cutting Capacity :

Cutting Capacity :