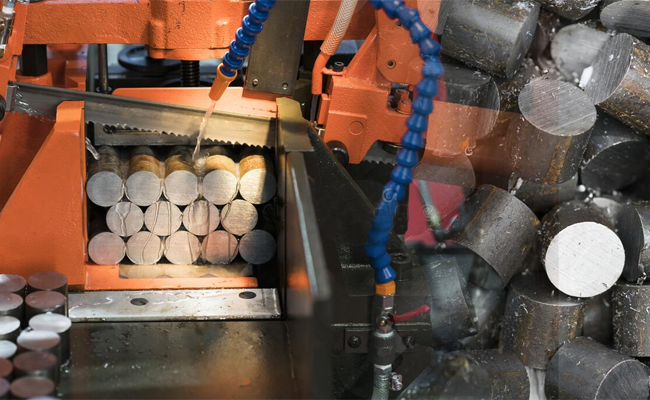

HS7150 Hydraulic Hack Saw

Cutting Capacity :

Band sawing machine is a kind of cutting equipment widely used in industrial production, mainly used for cutting various materials. Different materials have different mechanical properties and cutting characteristics, so the sawing speed of various materials needs to be considered in the operation of band sawing machine.

In the sawing processing of metal materials, commonly used materials are steel, aluminum and copper. These metal materials have high hardness and toughness, so it is necessary to select a suitable sawing speed to ensure the quality and efficiency of processing.

1. Sawing speed of steel:

Steel has poor cutting performance, so a lower cutting speed is required. Generally, the sawing speed of steel is 10-20 meters/minute. When selecting the cutting speed, factors such as the hardness and cross-sectional shape of the steel also need to be considered.

2. Sawing speed of aluminum:

Aluminum has good cutting performance, so a higher cutting speed can be selected. Generally, the sawing speed of aluminum is 20-30 meters/minute. It is worth noting that due to the good thermal conductivity of aluminum, it needs to be cooled in time during the sawing process to avoid thermal deformation of the material.

3. Sawing speed of copper:

The cutting performance of copper is between that of steel and aluminum, so its cutting speed is also at a medium level. Generally, the sawing speed of copper is 15-25 m/min. When sawing copper, you also need to pay attention to the oxidation problem on the surface of the material to avoid affecting the cutting effect.

In addition to metal materials, band saws are also commonly used to cut non-metallic materials such as wood and plastic. Because wood and plastic have lower hardness and toughness, their sawing speed is higher.

1. Sawing speed of wood:

Wood has good cutting properties, so a higher sawing speed is generally selected. When choosing the sawing speed of wood, factors such as the material and humidity of the wood need to be considered. Generally, the sawing speed of wood is 30-40 m/min.

2. Sawing speed of plastic:

Plastic has better cutting performance, so a higher sawing speed can be selected. Generally, the sawing speed of plastic is 30-50 m/min. When cutting plastic, it is necessary to avoid excessive temperature from damaging the material.

In addition to metal, wood and plastic, band saws can also be used to cut some special materials, such as stone, ceramics and glass.

1. Cutting speed of stone:

Stone has high hardness and brittleness, and it is easy to crack and break during the cutting process. Therefore, a lower sawing speed needs to be selected when cutting stone. Generally, the sawing speed of stone is 5-10 meters per minute.

2. Cutting speed of ceramics and glass:

Ceramics and glass have extremely high hardness and brittleness, so the cutting speed is very low. When cutting these materials, diamond band saw blades are generally used, and water cooling is used for cutting. This can avoid material breakage and surface damage.

In general, band saws need to choose appropriate sawing speeds when cutting different materials. By reasonably selecting and adjusting the sawing speed, the quality and efficiency of material processing can be ensured. At the same time, attention should also be paid to lubrication and cooling during the sawing process to avoid thermal deformation of the material and surface damage.

Cutting Capacity :

Cutting Capacity :