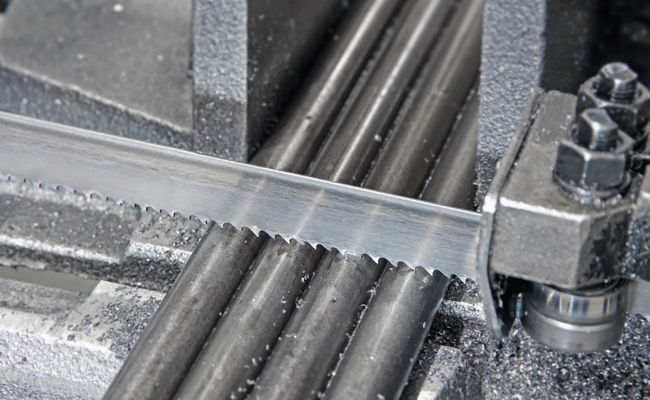

BS-180G Horizontal Band Saw

Cutting Capacity :

Don’t Waste Money on the Wrong Blade. Find Your Perfect Match in Minutes.

Choosing the best band saw blade for cutting metal can be confusing. With so many types and specifications, it’s easy to pick the wrong one, leading to broken blades, rough cuts, and wasted time.

The truth is, there is no single “best” blade for all jobs. The best blade depends on the material you’re cutting and the type of cut you want to make.

This guide breaks down the complex world of band saw blades into simple, actionable steps. Let’s find your ideal blade.

Think of selecting a blade as a three-step process. Get these right, and you’ll have perfect cuts every time.

Blade Material (What the blade is made of)

Tooth Pitch (The size and spacing of the teeth)

Tooth Geometry (The shape of the teeth)

The blade material determines its hardness, durability, and what it can cut. Here are the most common types:

| Blade Type | Best For | Key Characteristics |

|---|---|---|

| Carbon Steel | Soft metals (aluminum, copper), wood, plastics. | Economical and flexible. Not for hard steel. Wears out quickly. |

| Bi-Metal (The Most Popular Choice) | General-purpose cutting. Excellent for steel, stainless steel, alloys, and more. | High-speed steel teeth welded to a flexible spring steel back. The best balance of durability, performance, and value. |

| Carbide-Tipped | Abrasive & very hard materials like titanium, cast iron, superalloys, and reinforced plastics. | Extremely hard teeth for long life in tough applications. Most expensive option. |

Key Takeaway: For most metal-cutting tasks, from structural steel to stainless steel pipes, a Bi-Metal blade is the best and most versatile choice.

Tooth pitch is the number of teeth per inch (TPI). Choosing the correct TPI is critical for a smooth and efficient cut.

Low TPI (2-3 TPI): Big, aggressive teeth for fast cutting in large, soft sections (e.g., thick aluminum beams).

Medium TPI (6-10 TPI): The all-rounder. Ideal for general-purpose cutting of solid bars, pipes, and structural steel.

High TPI (14-24 TPI): Small, closely spaced teeth for thin-walled materials (e.g., tubing, sheet metal) to prevent tooth snagging and breakage.

Always have at least 3 teeth in contact with the workpiece. This prevents the teeth from getting caught and snapping.

Use this quick-reference chart:

| Material Type | Recommended TPI |

|---|---|

| Thick Solid Sections (>1″ thick) | 3-4 TPI |

| General Purpose / Mixed Use | 6-8 TPI |

| Thin-Walled Tube & Pipe | 10-14 TPI |

| Sheet Metal & Thin Plate (<1/8″) | 18-24 TPI |

The shape of the tooth affects how it enters the material and removes chips.

Regular / Raker: The most common pattern. Teeth are set in a left-right-straight (rake) pattern. Ideal for most solid materials like bars and structural steel.

Hook: Has a deep, aggressive gullet (space between teeth) and a 10-degree rake angle. Cuts faster and is better for softer metals like aluminum and softer steels.

Wavy: The teeth are set in a wave pattern. Designed specifically for cutting thin sheet metal, tubing, and cross-sectional shapes where a raker or hook tooth would cause vibration and breakage.

| If You Are Cutting… | Your Best Blade Choice |

|---|---|

| Mild Steel, Structural Steel, Alloy Steel | Bi-Metal, Hook Tooth, 6-8 TPI |

| Stainless Steel | Bi-Metal, Raker or Hook Tooth, 8-10 TPI |

| Aluminum & Soft Metals | Bi-Metal, Hook Tooth, 2-4 TPI (for thick material) |

| Thin-Walled Tube & Pipe | Bi-Metal, Wavy Tooth, 10-14 TPI |

| Abrasive Materials (Titanium, Cast Iron) | Carbide-Tipped Blade |

Before you purchase your band saw blade, do a quick check:

Material: Am I cutting hard steel, soft aluminum, or something else?

Shape & Size: Is it a solid bar, a pipe, or a thin sheet?

TPI: Do I have enough teeth in contact with the material? (Refer to the TPI chart above).

Blade Type: For 90% of jobs, a Bi-Metal blade is the answer.

By following this simple guide, you can confidently select the best band saw blade for your specific metal-cutting task, saving you money, time, and frustration. Happy cutting!

Cutting Capacity :

Cutting Capacity :