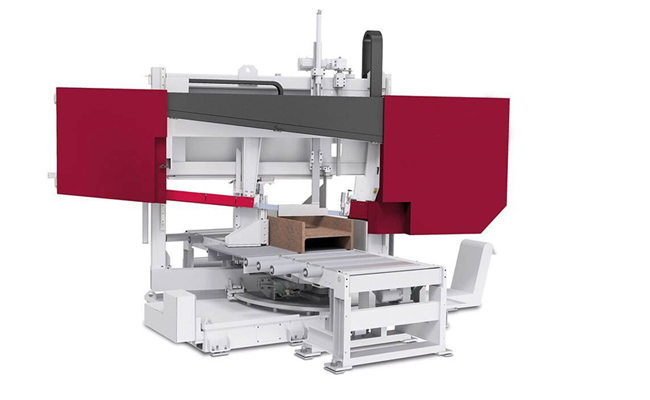

TGK-4235 Double Column Band Saw

Cutting Capacity :

In modern manufacturing, CNC metal sawing machines, as efficient and precise cutting equipment, are widely used in the metal processing industry. Choosing a high-quality CNC metal sawing machine can not only improve production efficiency but also ensure product quality and reduce operational costs. However, faced with a plethora of products on the market, how can one make an informed decision? This article provides comprehensive guidance from multiple perspectives.

1. Brand and Reputation: Choosing a Reliable Manufacturer

When selecting a CNC metal sawing machine, brand and reputation are the primary considerations. Well-known brands such as Amada, Kasto, and Behringer typically possess mature technology and extensive industry experience, offering more reliable product quality and after-sales service. Additionally, user reviews, industry forums, or consultations with peers can provide insights into the machine’s real-world performance, helping to avoid products with unstable quality or poor after-sales support.

2. Technical Specifications: Meeting Production Needs

Technical specifications are the core indicators for evaluating the performance of a CNC metal sawing machine. Choose based on your production requirements:

Cutting Capacity: Select a machine model suitable for the type, thickness, and diameter of the materials to be processed, ensuring efficient cutting performance.

Cutting Precision: High-precision machines reduce errors and improve product quality, especially in industries with strict dimensional requirements.

Cutting Speed: Cutting speed directly impacts production efficiency, so choose a machine that aligns with your production pace.

Automation Level: Features such as automatic feeding, clamping, and chip removal can significantly enhance efficiency and reduce manual intervention.

3. Structure and Materials: Ensuring Machine Stability

The structure and materials of the machine directly affect its lifespan and cutting performance:

Machine Stability: A robust frame minimizes vibrations, improves cutting accuracy, and extends the blade’s service life.

Key Component Quality: The quality of critical components such as blades, guides, and servo motors determines the machine’s overall performance. Choose durable and reliable parts.

4. Control System: User-Friendly and Powerful

The CNC system is the core of a CNC metal sawing machine, and its performance directly impacts the user experience and cutting results:

CNC System: Opt for a powerful and user-friendly CNC system that supports multiple programming methods and automation features to meet complex processing needs.

User Interface: An intuitive interface reduces operational complexity, lowers training costs, and improves production efficiency.

5. Safety Features: Ensuring Operational Safety

Safety is a critical factor that cannot be overlooked when selecting a CNC metal sawing machine:

Safety Protections: The machine should be equipped with essential safety devices, such as emergency stop buttons, protective covers, and overload protection, to ensure operator safety.

Compliance with Standards: The machine should meet relevant industry safety standards to ensure safe design and usage.

6. After-Sales Service: Long-Term Support

High-quality after-sales service ensures the long-term stable operation of the machine:

Warranty Period: Choose a machine with a longer warranty period to reduce maintenance costs.

Technical Support: Ensure the supplier provides timely technical support and repair services to avoid production downtime due to equipment failure.

7. Cost-Effectiveness: Balancing Cost and Benefits

Cost-effectiveness is an important consideration when selecting a machine that meets production needs:

Price Comparison: Compare machines from different brands and models to choose the most cost-effective option.

Long-Term Costs: In addition to the machine price, consider energy consumption, maintenance costs, and consumable expenses to select a machine with lower overall costs.

8. On-Site Inspection and Sample Testing

Before making a final decision, conduct on-site inspections and sample testing:

Factory Visit: Visit the manufacturer’s facility to understand their production processes and quality control measures.

Sample Testing: Request a sample machine for testing to verify its actual performance and suitability for your needs.

Choosing a high-quality CNC metal sawing machine requires a comprehensive evaluation of factors such as brand, technical specifications, structure, control system, safety features, after-sales service, and cost-effectiveness. On-site inspections and sample testing can further validate the machine’s performance and quality. Only by selecting a machine that meets your production needs can you fully leverage its value and drive greater efficiency for your business. We hope this guide helps you find the most suitable CNC metal sawing machine among the many options available, empowering your business to achieve higher efficiency and success.

Cutting Capacity :

Cutting Capacity :