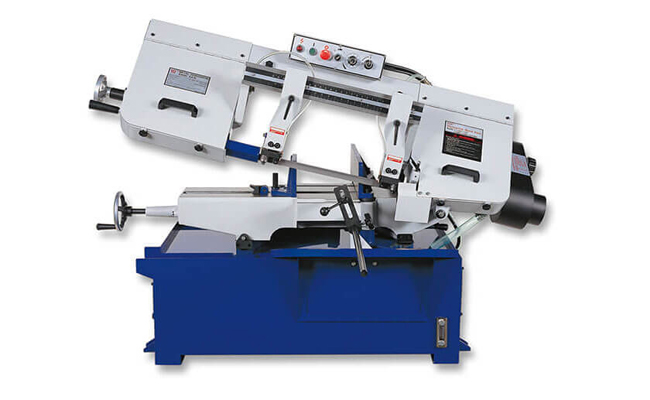

CS-380 Semi-Automatic Band Saw Machine

Cutting Capacity :

A fully automatic sawing machine is a high-efficiency, high-precision metal-cutting device widely used in metal processing, machinery manufacturing, automotive parts, aerospace, and other industries. It achieves unmanned operation through an automated control system, significantly improving production efficiency and cutting accuracy. Below is a detailed breakdown of fully automatic sawing machines.

A fully automatic sawing machine is a high-efficiency, high-precision metal-cutting device widely used in metal processing, machinery manufacturing, automotive parts, aerospace, and other industries. It achieves unmanned operation through an automated control system, significantly improving production efficiency and cutting accuracy. Below is a detailed breakdown of fully automatic sawing machines.

1. Core Components of Fully Automatic Sawing Machines

Mechanical Structure

Bed: Made of high-strength cast iron or welded steel to ensure stability and vibration damping.

Sawing System: Includes the saw blade (band saw/circular saw), guide mechanism, and tensioning device. Some models feature dual-column structures for enhanced rigidity.

Feeding System: Automatic feed racks, rollers, or robotic arms, paired with servo motors for precise material feeding.

Clamping Device: Hydraulic or pneumatic fixtures to prevent workpiece movement.

Control System

PLC/CNC Control: Programmable cutting parameters (speed, length, angle, etc.) with multi-task storage.

Human-Machine Interface (HMI): Touchscreen operation for setting cutting modes and monitoring faults.

Sensors: Detect material position, blade tension, and cutting status for closed-loop control.

Power System

Main Motor: Drives the saw blade at high speed, typically with a power range of 3-15 kW.

Hydraulic System: Controls clamping and feeding actions, with some models featuring energy-saving hydraulic pumps.

2. Workflow

Loading: Manual or automated feeding places the material onto the platform.

Positioning: Sensors or vision systems identify material dimensions, and clamps secure the workpiece.

Cutting: The saw adjusts speed and feed rate based on preset programs to complete the cut.

Unloading: Finished pieces are removed via chutes or robotic arms, with scrap automatically separated.

3. Key Technical Features

High-Precision Cutting

Repeat positioning accuracy up to ±0.1 mm, with smooth, burr-free cuts.

Laser calibration or grating scales ensure precision for demanding industries (e.g., precision molds).

Automation Capabilities

Batch Processing: Supports continuous cutting with automatic counting.

Smart Adjustment: Automatically adapts cutting parameters (e.g., variable speed) based on material hardness.

Self-Diagnostics: Alerts for blade breakage, overload, and other anomalies.

Energy Efficiency & Environmental Protection

High-efficiency motors and frequency conversion technology reduce power consumption.

Cutting fluid recycling systems minimize waste discharge.

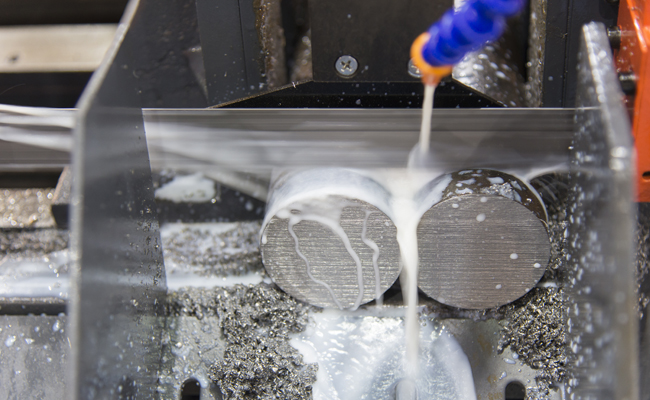

The band saw machine cutting the steel rod with the coolant

4. Classification & Applications

| Type | Features | Typical Applications |

|---|---|---|

| Horizontal Saw | Horizontal workpiece placement, ideal for long materials | Pipes, bars, profiles |

| Vertical Saw | Space-saving, suitable for short or complex shapes | Mold steel, gear blanks |

| Angle Saw | Adjustable cutting angles (0°-60°) | Steel structures, automotive frames |

| CNC Band Saw | High flexibility for curved cuts | Aerospace titanium components |

5. Selection Criteria

Material Properties: Hardness, diameter/cross-section (e.g., stainless steel requires higher power).

Production Needs: Batch processing may require automatic feeding and multi-station systems.

Precision Level: High-precision machining demands quality guide mechanisms and control systems (e.g., Siemens, Fanuc).

Additional Features: Connectivity (Industry 4.0), remote monitoring, etc.

6. Maintenance & Safety

Routine Maintenance:

Regularly inspect blade wear and lubrication levels.

Clear chips to prevent clogging.

Safety Operations:

Install protective covers to avoid hand contact near the cutting zone.

Ensure emergency stop buttons function properly.

Fully automatic sawing machines are increasingly replacing manual equipment through technological advancements. Users should select models based on actual needs, prioritize operator training, and perform regular maintenance to maximize efficiency.

Cutting Capacity :

Cutting Capacity :