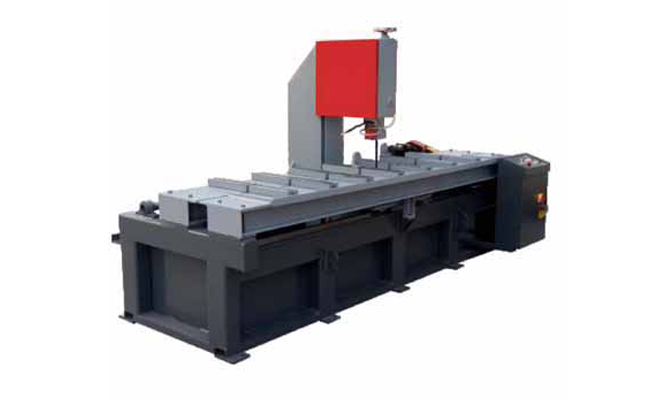

DLY-18F1 Manual Band Saw Machine

Cutting Capacity :

In industrial manufacturing, metalworking, and many other fields, band saws are indispensable tools for cutting operations.

With their efficient and precise cutting performance, they help us cut a variety of materials to meet our needs.

There are many different types of band saws, each with unique advantages and applications.

Horizontal Band Saws

Horizontal band saws are the most common type of band saw. Their saw frame is positioned horizontally.

Structural Features: Their overall structure is relatively stable, with a wide work surface that easily accommodates workpieces, whether long metal profiles or bulk materials. The saw blade runs horizontally, maintaining relatively stable blade tension during cutting, ensuring a smooth cutting motion.

Applications: They are widely used for cutting various metal materials, such as steel, aluminum, and copper. Horizontal band saws, with their wide worktable and stable cutting performance, are particularly effective for cutting large and long metal workpieces.

Vertical Band Saws

Unlike horizontal band saws, vertical band saws have a vertical frame, presenting an upright and efficient appearance.

Structural Features: They occupy a relatively small footprint, allowing for flexible placement in workshops or processing areas with limited space. The vertical blade runs, making it easier to operate when cutting workpieces of a certain height. Furthermore, the vertical frame design makes it easier to maintain blade verticality during cutting, improving cutting accuracy.

Applications: Vertical band saws are particularly suitable for cutting blocky or cylindrical metal or non-metallic materials. For example, in the mold manufacturing industry, when blocks of mold steel need to be cut to obtain modules of the correct size, vertical band saws are highly effective with their precise cutting accuracy. Vertical band saws are also effective for applications requiring segmented cutting of cylindrical materials, such as cutting logs into sections during wood processing.

CNC Band Saws

With the continuous advancement of technology, CNC band saws have emerged as the “smart” members of the band saw family.

Structural Features: Equipped with advanced CNC systems, these machines precisely control various cutting parameters, such as cutting speed, feed rate, and blade trajectory, through programming. They are often equipped with automatic feeding devices, enabling automated feeding and cutting operations, significantly improving production efficiency.

Applications: These band saws are primarily used in applications requiring extremely high cutting precision, complex cutting tasks, and large production runs. For example, in the aerospace industry, CNC band saws can precisely perform cutting tasks according to pre-set programs for precision cutting of special alloy materials, ensuring dimensional accuracy and quality requirements. In the automotive parts manufacturing industry, the automation and high-precision advantages of CNC band saws are fully utilized for cutting large quantities of metal parts of the same specifications.

Semi-automatic Band Saws

Semi-automatic band saws can be considered a transitional type between traditional manual band saws and CNC band saws.

Structural Features: While they offer certain automated features, such as automatic blade tensioning and partial material feeding assistance, they lack the fully programmable control of the cutting process like CNC band saws. Operators still need to manually operate and monitor key steps, such as adjusting the cutting speed based on the actual situation.

Application: Semi-automatic band saws are suitable for cutting tasks that require a certain level of precision but do not require the high-precision control of CNC band saws. For example, in small machining shops processing metal workpieces with medium-precision requirements, semi-automatic band saws can improve efficiency while ensuring cutting quality with minimal operator intervention.

When choosing a band saw, consider a comprehensive range of factors, including your specific processing needs, cutting accuracy requirements, production batch size, and site space. This will help you select the most suitable band saw for your specific needs, ensuring efficient and precise cutting.

Cutting Capacity :

Cutting Capacity :