This is an excellent question that gets to the heart of efficiency and cost in metal cutting. Here’s a detailed breakdown of the differences between semi-automatic, fully automatic, and CNC band saws.

The core difference between these three types lies in the level of operator involvement, control, and automation in the cutting process.

1. Semi-Automatic Band Saw

This is the most common type of industrial saw, representing a significant upgrade from a manual saw.

-

How it Works: The operator manually loads the material into the vise and sets the desired cut length (often using a mechanical measuring tape or a simple digital readout). Once the cycle is started, the automation takes over: the saw head lowers, makes the cut, and returns to the top. The operator then must manually unload the cut piece and reset for the next cut.

-

Key Feature: Automation of the cutting cycle only. The loading, measuring, and unloading are manual.

-

Pros:

-

Lower initial cost than fully automatic or CNC models.

-

Good for mixed batches where cut lengths change frequently.

-

Faster and more consistent than a purely manual saw.

-

Cons:

-

Requires an operator to be present for every cycle.

-

Productivity is limited by the operator’s speed.

-

Higher potential for measurement errors on each part.

-

Best For: Job shops, maintenance departments, and smaller production runs where the volume doesn’t justify a more expensive machine or where a dedicated operator is available.

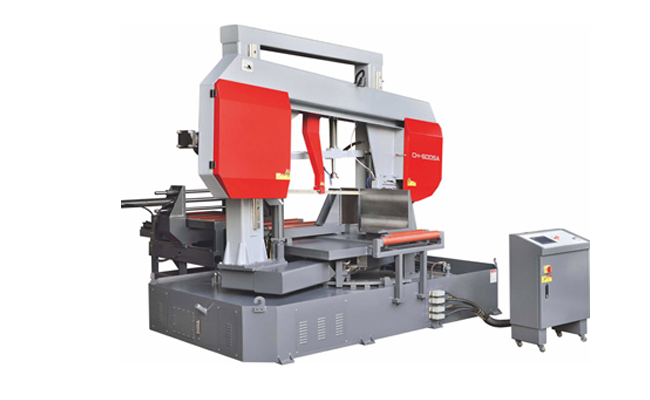

2. Fully Automatic Band Saw

This type removes the operator from the measurement and cycle-starting process, focusing on high-volume production of repetitive cuts.

-

How it Works: The operator loads a bundle of material (often multiple bars) into an infeed magazine or conveyor. The machine is programmed with a single cut length (e.g., cut 10,000 pieces at 24 inches). An automated vise and measuring system position the material, make the cut, and an outfeed conveyor or stacker unloads the finished pieces automatically. Some advanced models can read barcodes on the material to automatically call up cutting programs.

-

Key Feature: Fully automated cycle, including feeding, measuring, cutting, and unloading. Designed for one length until the program is changed.

-

Pros:

-

Very high productivity for long runs of the same part.

-

Can run unattended for long periods (lights-out operation).

-

Extremely consistent and eliminates human measurement error.

-

Cons:

-

Inflexible. Changing the cut length requires stopping the machine and reprogramming, which kills efficiency.

-

Higher initial cost.

-

Not suitable for short runs with frequently changing lengths.

-

Best For: High-volume production environments, such as steel service centers or manufacturers that need thousands of identical parts cut from long stock.

3. CNC Band Saw

This is the most advanced and flexible option. A CNC (Computer Numerical Control) system manages all aspects of the cutting process with precision and can easily switch between different programs.

-

How it Works: Like a CNC mill or lathe, the machine is controlled by a computer. The operator loads a bundle of material and selects a program from the machine’s memory. The CNC system then:

-

Automatically moves the material to the precise length (via a servo-driven feed system).

-

Makes the cut.

-

May also automatically index and flip material to make multiple cuts on a single piece.

-

Unloads finished parts.

-

Key Feature: Computer control over the entire process, allowing for complex, variable cutting sequences without operator intervention.

-

Pros:

-

Ultimate flexibility. Can run a batch of 10 pieces at one length, then immediately switch to a different program for a batch of 50 pieces at another length.

-

High precision and repeatability due to servo motors and ball screws.

-

Optimizes material usage with features like remnant management.

-

Capable of complex cuts (notching, mitering, multiple cuts on one part).

-

Cons:

-

Best For: Job shops and production facilities that handle high-mix, low-volume work. Ideal for cutting expensive material (e.g., titanium, stainless steel) where precision and minimizing waste are critical.

Comparison Table

Summary & Analogy

Think of it like making sandwiches:

-

Semi-Automatic: You tell the chef how long to cut the bread for each sandwich. They automatically slice it perfectly, but you have to hand them each new loaf and tell them the length again.

-

Fully Automatic: You load a giant pile of bread and tell the machine “1-inch slices.” it will make thousands of identical 1-inch croutons until it runs out of bread or you stop it.

-

CNC: You load the bread and tap a screen. The machine makes 5 club sandwiches (each with three different slice types), then switches to making 20 normal sandwiches, then makes 10 subs, all perfectly measured and without you needing to intervene.