QCS-400 Circular Saw

Cutting Capacity :

When it comes to metalworking, selecting the right cutting tool is crucial for efficiency, accuracy, and safety. Two popular options are the horizontal band saw and the metal cutting miter saw. Both tools have distinct advantages and are suited for different tasks. This article will compare these two types of saws, break down their features, and help you decide which one is best for your needs.

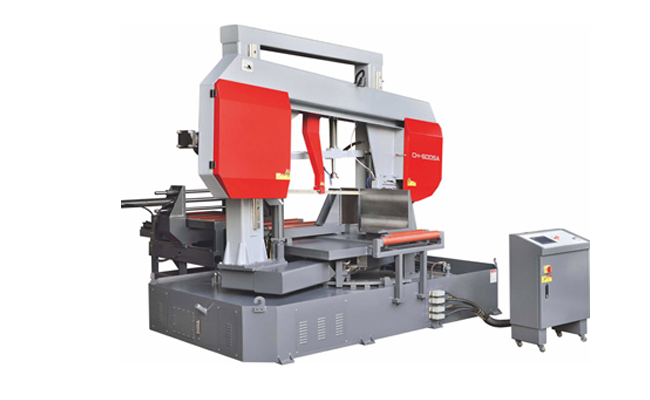

A horizontal band saw is a powerful tool designed primarily for cutting metal stock. It uses a continuous band blade that moves in one direction to make straight or angled cuts. The workpiece remains stationary while the blade swings down to cut through the material.

Ideal for cutting large metal pieces like bars, pipes, and tubing.

Provides clean, precise cuts with minimal material waste.

Can make miter cuts by adjusting the vise angle.

Often used in industrial settings and workshops.

A metal cutting miter saw (also known as a chop saw or abrasive saw) is a portable tool that uses a circular blade to make quick, straight, or angled cuts. Unlike wood miter saws, metal versions use specialized blades designed to handle ferrous and non-ferrous metals.

Excellent for cross-cutting and miter cuts in metal.

Fast and efficient for repetitive cuts.

Typically more portable and compact than horizontal band saws.

Uses abrasive discs or carbide-tipped blades for cutting.

To help you understand the differences, here’s a breakdown of both tools:

| Feature | Horizontal Band Saw | Metal Cutting Miter Saw |

|---|---|---|

| Primary Use | Cutting large metal stock | Cross-cutting and mitering metal |

| Cutting Accuracy | High precision | Good for rough to medium precision |

| Blade Type | Continuous band blade | Circular abrasive or carbide blade |

| Portability | Generally stationary | Portable and easy to move |

| Best For | Long cuts, thick materials | Quick, angled cuts |

| Price Range | $$$ (Higher cost) | $$ (More affordable) |

You need to cut large metal sections.

You require high precision and smooth finishes.

Your work involves long production runs.

You need a portable tool for on-site jobs.

You are making repetitive cross-cuts or miters.

Your budget is limited, but you still need reliability.

Regardless of which tool you use, safety should always come first. Here are some essential tips:

Wear Protective Gear – Always use safety glasses, gloves, and hearing protection.

Secure the Workpiece – Clamp down metal pieces to prevent movement.

Use the Right Blade – Ensure the blade is suitable for the material you are cutting.

Keep the Workspace Clean – Avoid clutter to reduce accident risks.

Both the horizontal band saw and the metal cutting miter saw are valuable tools for metalworkers. Your choice depends on the specific requirements of your projects, including the type of cuts, material size, and need for portability. By understanding the strengths of each tool, you can make an informed decision that enhances your workshop’s productivity.

Cutting Capacity :

Cutting Capacity :