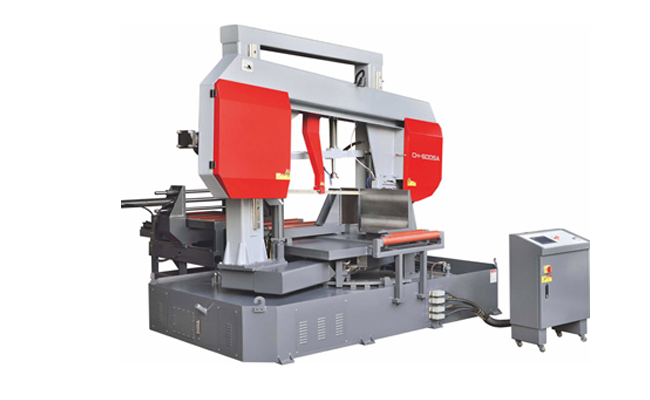

430A Fully Automatic Band Saw Machine

Cutting Capacity :

In the world of metal fabrication, construction, and machining, the first and most critical step is often the simplest: cutting the raw material to size. While abrasive chop saws, cold saws, and plasma cutters all have their place, nothing matches the efficiency, versatility, and cost-effectiveness of a horizontal cutting bandsaw for straight, precise cuts on metal stock. From chopping structural beams to slicing delicate tubing, this workhorse machine is a foundational piece of equipment in any serious metalworking shop.

Choosing the right one, however, is not a simple task. It requires a deep understanding of your needs, the machine’s capabilities, and the technology behind it. This ultimate guide will explore the different types of horizontal bandsaws, break down the critical specifications, and provide essential tips for operation, safety, and maintenance to ensure you invest in a machine that boosts your productivity for years to come.

Not all horizontal bandsaws are created equal. They are primarily categorized by their mode of operation and level of automation, which directly correlates to price and production capability.

1. Manual Horizontal Bandsaws

The most basic type, manual bandsaws, require the operator to physically lift the saw head or pivot the cutting arm to initiate the cut. The feed rate (the speed at which the blade descends into the material) is controlled by a hand valve regulating hydraulic dampening.

Best For: Low-volume shops, maintenance departments, hobbyists, and educational settings. They are perfect for jobs where every cut is different and cycle time is not a critical factor.

Pros: Lowest cost, simple to operate and maintain, no electrical controls needed for feed.

Cons: Operator-dependent results, inconsistent feed rate can lead to premature blade wear, requires constant operator attendance.

2. Semi-Automatic Horizontal Bandsaws

This is the most common type found in general machine shops. Semi-automatic saws feature an electric motor to raise and lower the saw head. The operator clamps the material, sets the cutting length via a mechanical stop, and presses a button. The machine then performs the entire cut cycle automatically, including feeding the blade and shutting off once the cut is complete.

Best For: General machining, fabrication shops, and any environment with a mix of production runs and one-off cuts.

Pros: Excellent consistency, frees up the operator for other tasks, improves blade life through consistent hydraulic or electronic feed pressure control, vastly improved productivity over manual models.

Cons: Higher initial cost than manual models.

3. Fully Automatic / CNC Horizontal Bandsaws

The pinnacle of cutting automation, CNC bandsaws integrate a programmable logic controller (PLC) to manage every aspect of the cutting process. They often include automatic material feeding systems (length stops and load/unload conveyors), built-in chip conveyors, and sophisticated sensors.

Best For: High-production environments, steel service centers, and any application requiring unattended operation, precise repeatability, and integration with factory data systems.

Pros: Maximum productivity and efficiency, unparalleled consistency and precision, can run lights-out (unattended), reduces labor cost per cut, often includes advanced diagnostic and monitoring features.

Cons: Highest initial investment, requires more advanced programming and maintenance knowledge.

The bandsaw blade is the heart of the machine. Selecting the wrong blade for your material is the fastest way to get poor results and incur costly downtime. Three factors are critical: blade material, tooth pitch, and tooth geometry.

Blade Material:

Carbon Steel: An economical choice for cutting soft materials like wood, plastics, and non-ferrous metals. Not suitable for cutting steel.

Bi-Metal (M42): The industry standard for metal cutting. These blades feature a flexible carbon steel back for shock absorption and a high-speed steel (HSS) tooth edge for heat resistance and durability. They offer an excellent balance of performance and cost.

Carbide Tipped: Designed for the most demanding applications, carbide-tipped blades are used for cutting abrasive materials (like fiberglass, composites, and superalloys), hardened steels, and for achieving extremely long blade life in high-production environments. They are significantly more expensive but can outperform bi-metal blades 10-to-1 in certain applications.

Tooth Pitch (TPI – Teeth Per Inch):

Choosing the correct TPI is crucial for a smooth cut and long blade life. The goal is to have 2 to 3 teeth in contact with the workpiece at all times. Too few teeth can cause snagging and tooth stripping; too many teeth can cause gullet packing (chips clogging the blade) and overheating.

| Material Type & Size | Recommended TPI | Reason |

|---|---|---|

| Thin-Wall Tube & Sheet (< 1/8″) | 18-24 | High tooth count prevents teeth from catching and tearing thin material. |

| Solid Bar (1″ – 4″) | 10-14 | A moderate TPI provides efficient chip removal and good cutting speed. |

| Large Sections & Structural (> 4″) | 3-6 | Low TPI provides large gullets to clear the high volume of chips produced. |

| General Purpose Mix | 8-10 | A variable-pitch tooth pattern helps reduce vibration and is a good compromise. |

Tooth Geometry:

Regular Tooth: Uniform pitch and rake angle. Good for general cutting of most materials.

Variable Pitch (VP): The distance between teeth varies. This disrupts the harmonic vibration during cutting, resulting in a smoother cut, reduced noise, and extended blade life. Highly recommended for cutting tubing and irregular sections.

Hook Tooth: An aggressive positive rake angle (10°-15°) for fast, aggressive chip formation in softer materials like aluminum, wood, and plastics.

Raker Tooth: A neutral or slightly positive rake angle. The most common pattern for cutting ferrous metals (steel, iron). The set of the teeth (left-right bend) is typically in a raker pattern (one left, one right, one straight) for effective cutting and clearance.

A well-maintained bandsaw is a precise and profitable machine. Neglect leads to inaccurate cuts, broken blades, and major repairs.

Daily/Weekly:

Clean the Machine: Use a brush or chip shovel to remove chips from the saw table, vise, and base. Never use your hands.

Check Coolant Levels: Top up the coolant/kerf spray reservoir as needed. Use a quality water-soluble coolant designed for sawing to reduce heat, extend blade life, and improve cut finish.

Inspect the Blade: Look for signs of wear, cracked teeth, or dullness. A dull blade will require more pressure to feed, producing a wavy or burnt cut.

Lubricate: Grease the pivot points and guide arm rails according to the manufacturer’s manual.

Monthly/Bi-Monthly:

Check Wheel and Guide Alignment: Misaligned guide bearings or tracking will cause premature blade wear on one side and poor cuts.

Inspect Drive Belts: Check for cracks, glazing, or stretching. Replace if necessary.

Clean or Replace Coolant Filters: Ensure the coolant spray nozzles are not clogged.

Check Hydraulic Fluid: On semi-automatic models, check the fluid level and look for leaks.

Bi-Annually/Annually:

Drain and Replace Coolant: This prevents bacterial growth, rancidity, and machine corrosion. Thoroughly clean the tank during replacement.

Inspect Electrical Components: Check connections for tightness. Have a qualified electrician inspect the motor and wiring.

Check Vise Jaw Pressure: Ensure the hydraulic or mechanical vise is providing sufficient clamping force to prevent material from spinning.

The powerful and sharp nature of a bandsaw demands unwavering respect for safety protocols.

PPE is Mandatory: Always wear safety glasses, hearing protection, and heavy-duty gloves when handling material. Do not wear gloves near the moving blade during operation.

Secure the Workpiece: Always ensure the material is clamped tightly in the vise before starting the cut. A spinning workpiece can violently eject from the machine.

Keep Hands Clear: Never place your hands or fingers in line with the blade or near the cutting area when the machine is running.

Let the Machine Do the Work: Do not force the blade. Applying excessive feed pressure will break teeth and can break the blade.

Complete the Cut: Do not lift the saw head while the blade is still in the cut and moving. This will destroy the blade.

Machine Off for Adjustments: Always switch the machine off and disconnect the power before performing any maintenance, blade changes, or clearing a jammed blade.

Mind the Chips: The chips coming off the cut are sharp and hot. Use a brush or tool to clear them, never your hands.

Investing in the right horizontal bandsaw is an investment in your shop’s future capacity and profitability. The key is to match the machine’s capabilities to your specific needs.

For the Hobbyist or Maintenance Shop: A robust manual or entry-level semi-automatic model with a 7″ x 12″ cut capacity is often sufficient.

For the Job or Prototype Shop: A semi-automatic saw with a 10″ x 16″ to 14″ x 20″ capacity and features like a built-in coolant system and programmable length stops will dramatically improve workflow.

For High-Production and Steel Service: A fully automatic CNC bandsaw with dual-column construction for rigidity, automatic material indexing, and integrated handling is the only choice for maximizing throughput and ROI.

By understanding the types of saws available, the science of blade selection, and the discipline of maintenance and safety, you can harness the full potential of the horizontal bandsaw. It will become more than just a cutting tool; it will be the reliable, precise, and efficient first step in every project you undertake.

| Feature / Specification | Manual Bandsaw | Semi-Automatic Bandsaw | CNC Fully Automatic Bandsaw |

|---|---|---|---|

| Primary Use Case | Low-volume, custom cuts | Medium-volume, mixed production | High-volume, unattended production |

| Operator Involvement | High (entire process) | Medium (load, set, start) | Low (load magazine, program, monitor) |

| Cut Capacity (Typical) | 4″ x 6″ to 7″ x 12″ | 7″ x 12″ to 14″ x 20″ | 14″ x 20″ to 40″ x 40″+ |

| Cutting Accuracy | ±0.010″ – ±0.030″ | ±0.005″ – ±0.015″ | ±0.002″ – ±0.010″ |

| Blade Feed Control | Manual Hydraulic Valve | Automatic Hydraulic/Pneumatic | Programmable Servo Motor |

| Typical Blade Speed (FPM) | 40 – 300 (Variable) | 50 – 350 (Variable) | 50 – 450 (Programmable) |

| Initial Investment | $1,000 – $5,000 | $5,000 – $20,000 | $25,000 – $150,000+ |

| Key Advantage | Low Cost, Simplicity | Consistency, Operator Freedom | Throughput, Precision, Automation |

Cutting Capacity :

Cutting Capacity :