BS-115A Bandsaw

Cutting Capacity :

In metalworking and fabrication, precision cutting is crucial for efficiency and quality. One of the most reliable tools for this task is the industrial automatic horizontal metal bandsaw cutting machine. Designed for heavy-duty applications, this machine delivers high accuracy, speed, and durability, making it a must-have for workshops, factories, and metal processing plants.

What is an Automatic Horizontal Metal Bandsaw Cutting Machine?

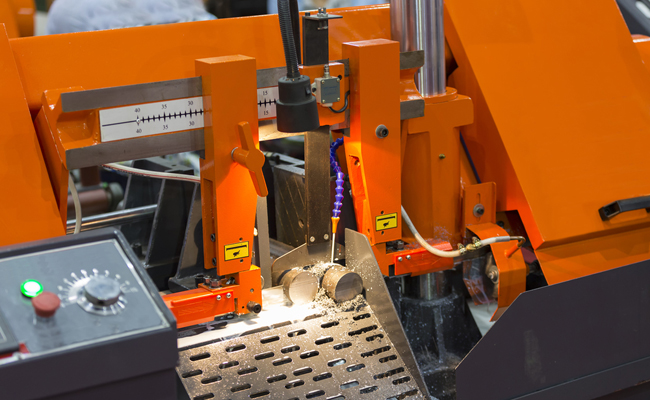

band saw cutting tool steel bar by automatic feed

An automatic horizontal metal bandsaw is a robust cutting machine designed to slice through metal bars, pipes, tubes, and solid blocks with precision. Unlike manual or semi-automatic saws, this fully automated machine operates with minimal human intervention, improving productivity and consistency.

Key Features

High Cutting Precision – Equipped with advanced blade guides and hydraulic or pneumatic feed systems, these machines ensure clean, burr-free cuts with tight tolerances.

Automatic Operation – Programmable controls allow for automated cutting cycles, reducing labor costs and human error.

Durable Construction – Built with heavy-duty steel frames and high-quality blades, these machines withstand continuous use in demanding industrial environments.

Versatility – Capable of cutting various metals, including steel, aluminum, copper, and alloys, in different shapes and sizes.

Efficient Chip Removal – Integrated chip conveyors or brushes keep the work area clean, preventing blade wear and overheating.

Safety Features – Emergency stop buttons, blade guards, and overload protection ensure safe operation.

Applications of Automatic Horizontal Metal Bandsaws

These machines are widely used in industries that require precise metal cutting, such as:

Metal Fabrication Shops – Cutting structural steel, beams, and pipes.

Automotive & Aerospace – Manufacturing components with exact dimensions.

Construction & Engineering – Preparing metal parts for frameworks and machinery.

Recycling Plants – Processing scrap metal into manageable sizes.

Advantages Over Other Cutting Methods

Compared to abrasive saws, circular saws, or plasma cutters, automatic horizontal bandsaws offer several benefits:

Lower Material Waste – Thin blades reduce kerf loss, saving material costs.

Cooler Cutting Process – Generates less heat, preserving metal properties.

Quieter Operation – Produces less noise than grinding or sawing alternatives.

Longer Blade Life – Proper tensioning and lubrication extend blade durability.

Choosing the Right Machine for Your Needs

When selecting an automatic horizontal bandsaw, consider:

Cutting Capacity – Maximum workpiece dimensions (diameter, width, length).

Blade Speed & Feed Control – Adjustable settings for different metals.

Automation Level – CNC-controlled models offer higher precision for complex cuts.

Brand & After-Sales Support – Reliable manufacturers provide maintenance and spare parts.

For industries that demand efficiency, precision, and durability in metal cutting, an automatic horizontal metal bandsaw machine is an indispensable investment. Its ability to handle high-volume production with minimal waste makes it a top choice for modern metal processing.

If you’re looking to upgrade your workshop or production line, investing in a high-quality bandsaw will improve cutting accuracy, reduce labor costs, and boost overall productivity.

Ready to enhance your metal cutting process? Explore top-rated automatic horizontal bandsaws today and find the perfect fit for your industrial needs!

Cutting Capacity :

Cutting Capacity :