G5350/110/300 Vertical Band Saw Machine

Cutting Capacity :

In the world of structural steel fabrication, few tasks are as fundamental or as critical as cutting large I-beams and H-beams. These essential components form the skeletons of buildings, bridges, and industrial projects, and the precision of their cuts directly impacts the integrity and efficiency of the entire structure. While abrasive chop saws and cold saws have their place, for superior cut quality, efficiency, and material savings, nothing outperforms a dedicated Band Saw Machine for I-Beams and H-Beams.

This ultimate guide will explore the different types of industrial band saws, delve into the critical factors for selection, and provide essential tips for care and safety to ensure you get the most out of your investment.

Not all band saws are created equal. The massive weight and complex profile of I-beams and H-beams demand robust, specialized machinery. Understanding the different types is the first step to choosing the right one.

1. Horizontal Band Saws:

The most common type for cutting stock to length. The blade moves in a horizontal plane, and the cutting head (or the material) pivots down through the workpiece.

Manual Horizontal Saws: Operated by hand, these are cost-effective for low-volume shops but are labor-intensive and inconsistent for high-precision work on large beams.

Semi-Automatic Horizontal Saws: Feature hydraulic or pneumatic systems to control the descent of the cutting head. The operator clamps the material and starts the cycle, greatly improving consistency and reducing operator fatigue.

Fully Automatic CNC Horizontal Saws: The pinnacle of cutting efficiency. Operators simply input the cut length and quantity into a CNC controller. The machine automatically handles material feeding (via a powered feed carriage), clamping, cutting, and part counting. Ideal for high-volume production and just-in-time manufacturing.

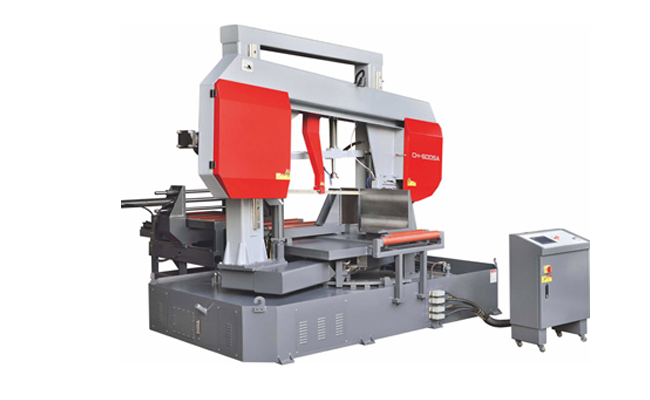

2. Dual Column (Gantry) Band Saws:

These are the heavy-duty champions of the band saw world. Featuring two massive vertical columns that support a rigid crossbeam, the saw head travels along this beam for incredibly straight and accurate cuts. The workpiece remains stationary on a large, sturdy base. This design is exceptionally rigid, minimizing vibration and deflection when cutting the thick webs and flanges of large beams, resulting in superior cut quality.

3. Tilting Head Band Saws:

A critical feature for structural fabrication. The ability to tilt the saw head (typically up to 45° or 60°) allows for cutting complex miters and bevels on beams without having to reposition the heavy workpiece. This is essential for creating the angled connections required in frameworks.

4. Portable Band Saws:

While not a replacement for a stationary machine, portable band saws are invaluable for making small, on-site cuts or trimming beams that are already in place. They are limited by their size and the need for manual operation.

Selecting the right machine is a significant investment. Here are the key technical factors to consider, complete with a data table for comparison.

1. Capacity: The Non-Negotiable Starting Point

Capacity is the most crucial factor. It’s defined in two ways:

Round Capacity: The maximum diameter of a solid round bar the saw can cut. (e.g., 18″).

Rectangular Capacity: The maximum width (W) x height (H) of a rectangular or structural shape it can accept. (e.g., 18″ W x 18″ H).

For I-beams and H-beams, you must consider the overall height (flange to flange) and the flange width. Always choose a saw with a capacity larger than the largest beam you plan to cut regularly.

2. Blade Size, Speed, and Feed

Blade Size (Width x Length): Wider blades (1.25″ to 2+ inches) are more rigid and provide straighter cuts on large sections. The machine will specify the required blade length.

Blade Speed (SFPM – Surface Feet Per Minute): Variable speed control is essential. Cutting steel requires a slower SFPM (100-300 SFPM) compared to aluminum or non-ferrous metals. The right speed ensures proper chip formation and extends blade life.

Hydraulic Feed Control: A consistent, automatic feed pressure is vital. It prevents the blade from being overloaded (causing breakage) or underfed (causing premature blade wear from rubbing).

3. Material Handling System

Moving heavy beams is a major safety and logistical concern.

Powered Infeed/Outfeed Rollers: These motorized rollers move the beam into position for cutting, drastically reducing manual labor and risk of injury.

Vises & Clamping: Look for a saw with a powerful, automatic clamping system that securely holds both the web and the flange of the beam to prevent movement during the cut, which is critical for accuracy.

4. Control System

Manual: Basic lever controls.

Semi-Automatic (PLC): Programmable Logic Controllers allow for setting cut parameters and repeating cycles with high consistency.

Full CNC: The most advanced option. CNC systems control everything: feed, speed, clamping, material length, miter angles, and part counting. They can be integrated with plant software for seamless production flow.

5. Structural Beam-Specific Features

Flange Guides: These are physical guides or rollers that stabilize the flanges of the beam during the cut to prevent vibration and twisting.

Notching Function: Some advanced CNC saws can perform notching operations in addition to cutting to length, combining two processes into one machine.

Comparative Data Table: Industrial Band Saws for Structural Beams

| Feature | Standard Horizontal Saw | Semi-Automatic Saw | CNC Dual Column Gantry Saw |

|---|---|---|---|

| Max Capacity (Example) | 18″ Round / 18″x18″ Rect. | 20″ Round / 20″x20″ Rect. | 24″ Round / 30″x30″ Rect. |

| Operation | Manual | Semi-Automatic (PLC) | Fully Automatic (CNC) |

| Mitering Capability | Manual tilting (if available) | Power tilting (e.g., 0-60°) | CNC power tilting (0-60°+) |

| Material Feeding | Manual | Manual or Powered Rollers | Fully Powered CNC Servo Feed |

| Typical Blade Width | 1″ – 1.25″ | 1.25″ – 1.5″ | 1.5″ – 2.5″+ |

| Best For | Low-volume, general shop use | Medium-volume structural fab shops | High-volume production, JIT manufacturing |

| Primary Advantage | Low Cost | Good balance of cost and consistency | Maximum output, precision, and automation |

| Estimated Cut-Off Tolerance | ±1/16″ to ±1/8″ (±1.5mm to ±3mm) | ±1/32″ (±0.8mm) | ±0.010″ to ±1/64″ (±0.25mm to ±0.4mm) |

Choosing the correct band saw blade is as important as choosing the saw itself. The wrong blade will lead to poor cuts, wasted material, and frequent breakages.

The Golden Rule: 3-4 Teeth in the Cut.

You should always have between 3 and 4 teeth engaged in the material you are cutting at any time.

Too Few Teeth (e.g., a coarse blade on a thin web): The teeth can snag and strip, pulling out gullets or breaking the blade.

Too Many Teeth (e.g., a fine blade on a thick flange): The chip gullets become packed, preventing efficient chip removal. This creates heat, friction, and rapid blade dulling.

Selecting the Right Pitch (TPI – Teeth Per Inch):

For large, solid sections or thick flanges (4″+): Use a coarse blade with 2-3 TPI. This provides large gullets to clear the significant volume of chips.

For cutting the thinner web of an I-beam (0.5″ – 1″): Use a medium blade with 4-6 TPI.

For cutting structural tubing or thinner wall sections: A finer blade with 7-10 TPI may be required.

Variable-Pitch Blades: The best choice for most structural applications. These blades alternate between high and low tooth pitches. This variation disrupts harmonic vibration (which causes chatter and poor finish) and allows one blade to perform well on a variety of thicknesses found in a single beam.

Blade Material:

Bi-Metal (M42): The industry standard. A high-speed steel tooth edge welded to a flexible alloy steel back. Offers an excellent balance of wear resistance, durability, and cost-effectiveness.

Carbide-Tipped: For the most demanding applications, cutting abrasive materials (like fiberglass or composites attached to steel), or for extremely long blade life in production environments. More expensive but lasts significantly longer.

A well-maintained band saw is a productive and accurate saw. Neglect leads to downtime and costly repairs.

Daily Maintenance:

Clean the Machine: Brush away all chips and debris from the vise, table, and guides. Use a vacuum or brush, never compressed air, which can force chips into bearings and ways.

Check Coolant Level: Ensure the reservoir is full. Dirty coolant should be replaced periodically.

Inspect the Blade: Look for signs of wear, cracked teeth, or dullness. A dull blade costs more in wasted material and time than a new blade does.

Lube the Ways: Lightly lubricate the guide ways and pivot points as specified by the manufacturer.

Weekly/Monthly Maintenance:

Check Band Wheel Tires: Inspect for cracks or wear.

Inspect Guide Bearings: Ensure they spin freely without play. Worn guides will ruin a blade quickly.

Check Hydraulic System: Look for leaks and check fluid levels.

Check Drive Belt Tension: Ensure they are tight and not cracked.

Break-In a New Blade: A crucial step often skipped. Run a new blade at reduced feed and speed for the first 50-100 square inches of cut area. This gently wears the sharp, brittle tooth edges and prepares them for a long life of maximum performance.

Safety must always be the top priority when operating powerful industrial machinery.

PPE (Personal Protective Equipment) is Mandatory:

Safety glasses with side shields or a face shield.

Heavy-duty work gloves for handling material. (Note: Avoid loose gloves near rotating parts during actual machine operation).

Steel-toed boots.

Hearing protection.

No loose clothing, jewelry, or long hair that could be caught in machinery.

Operational Safety:

Read the Manual: Understand all machine functions and safety interlocks.

Ensure Guards are in Place: Never operate a saw with safety guards removed.

Secure the Workpiece: Double-check that the beam is clamped securely against both the fixed and moving vise jaws before starting the cut.

Let the Saw Do the Work: Never force a cut or override the feed control. This will break the blade.

Stay Alert: Do not operate machinery if you are tired or distracted.

Unplug for Service: Always disconnect the machine from power before performing any maintenance or blade changes.

Investing in the correct industrial band saw for I-beams and H-beams is a strategic decision that pays dividends across your entire operation.

Efficiency: Automated material handling and CNC controls drastically reduce cutting time and labor costs.

Precision: Accurate, square cuts right out of the saw minimize or eliminate secondary grinding and fitting operations, speeding up fabrication and assembly.

Material Savings: A thin band saw kerf (cut width) generates less waste than an abrasive saw, saving material over thousands of cuts. Straight cuts also allow for tighter nesting on raw stock.

Quality: A superior cut finish with no heat-affected zone (HAZ) or hardening from friction provides a better starting point for welding and painting.

By carefully considering your capacity needs, production volume, and the advanced features available, you can select a band saw machine that becomes the cornerstone of a more efficient, safer, and more profitable structural steel fabrication workflow.

Cutting Capacity :

Cutting Capacity :