1. By Orientation (Frame Design & Cutting Action)

This is the most fundamental classification.

A. Vertical Band Saws

The blade runs vertically on a large, rotating wheel assembly. The workpiece is placed on a horizontal table and is fed into the blade by the operator or an automated system.

-

Primary Use: Contour cutting (curves, intricate shapes), notching, and straight cutting of large, flat stock.

-

Key Features:

-

Table Tilts: The table often tilts for cutting bevels.

-

Blade Welding: Many have a built-in blade welder to create custom-length blades for internal cuts (drill a pilot hole, thread the blade through, and weld it back together).

-

Common Applications: Die-making, template creation, metal fabrication shops, prototyping.

B. Horizontal Band Saws

The blade runs horizontally, and the cutting head (containing the blade and motor) pivots down into the workpiece, or the workpiece moves into the blade. The material is held stationary in a vise.

-

Primary Use: Cut-off work – cutting long stock (bar, tube, pipe, structural beams) to a specific length. This is the most common type found in metal service centers and machine shops.

-

Key Features:

-

Common Applications: Cutting bar stock, preparing blanks for machining, processing tubing and pipe.

2. By Mode of Operation & Automation

This classification often overlaps with the orientation, defining how the saw is controlled.

A. Manual Band Saws

The operator physically performs the cutting action.

-

Vertical: The operator moves the workpiece by hand along the table to follow a line or pattern.

-

Horizontal: The operator uses a handwheel to lower the cutting head onto the workpiece. They control the feed rate and pressure.

-

Pros: Low cost, simple to operate and maintain.

-

Cons: Highly dependent on operator skill, inconsistent results, labor-intensive, low productivity for repetitive tasks.

B. Semi-Automatic Band Saws

The cutting cycle is automated, but loading and unloading are manual.

-

How it Works: The operator clamps the material, sets the desired length, and presses a start button. The saw automatically performs the cut: it lowers the blade, controls the feed rate, retracts the blade when done, and resets for the next piece. The operator then unloads the cut piece and loads new material.

-

Primary Use: High-production cut-off work. This is the workhorse for many industrial shops.

-

Pros: Excellent consistency, much higher productivity than manual saws, reduces operator fatigue.

C. Fully Automatic / CNC Band Saws

These are the most advanced saws, integrating Computer Numerical Control (CNC) for complete automation.

-

How it Works: The operator loads a bundle of material into a feeding system (like a magazine or conveyor). The CNC system automatically clamps the material, feeds it to the correct length, makes the cut, and unloads the finished pieces. For Vertical CNC Saws, the blade and/or table move on multiple axes (X, Y, and sometimes Z) to cut complex shapes directly from a CAD file.

-

Key Features:

-

Automatic Material Handling: Bar feeders, magazine feeders, and robotic arms for loading/unloading.

-

CNC Control: For horizontal saws, this controls length, quantity, and sometimes bundle cutting. For vertical saws, it controls the path of the blade to create complex 2D or 3D shapes.

-

Pros: Unmanned operation, extremely high productivity, perfect for lights-out manufacturing, exceptional accuracy and repeatability.

-

Common Applications: High-volume production cells, cutting complex aerospace components, automated structural steel fabrication.

3. By Specialized Design & Application

Beyond the common types, there are specialized band saws for specific tasks.

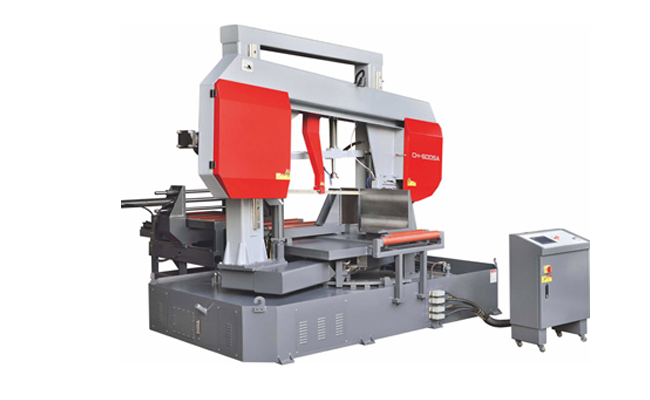

A. Double Column / Production Band Saws

A heavy-duty subtype of horizontal band saws. They feature a massive, fixed frame (like two columns) and a moving table that carries the workpiece through the stationary blade. This design provides extreme rigidity and accuracy for cutting large, heavy beams and solid billets.

B. Tilting Frame Band Saws

A subtype of horizontal saws where the entire frame (blade, wheels, motor) tilts to cut complex compound miters (angles in two planes) without having to reposition the workpiece. Crucial for structural steel and frame fabrication.

C. Cold Saws (Circular) vs. Band Saws

While not a band saw, it’s a key competitor. Cold Saws use a circular blade that operates at low RPM with high torque and flood coolant. They produce a superior, burr-free finish with exceptional accuracy but are generally slower and more expensive than band saws for cut-off work.

Summary Table

In summary, the choice of an industrial band saw depends entirely on the application:

-

Need to cut shapes? -> Vertical Band Saw (Manual or CNC).

-

Need to cut stock to length? -> Horizontal Band Saw (choose Manual, Semi-Auto, or Full-Auto based on your volume and budget).

-

Need high-volume, unattended cutting? -> CNC Automatic Horizontal with a bar feeder.

-

Need to cut large structural beams with complex angles? -> Tilting Frame Horizontal or Double Column saw.