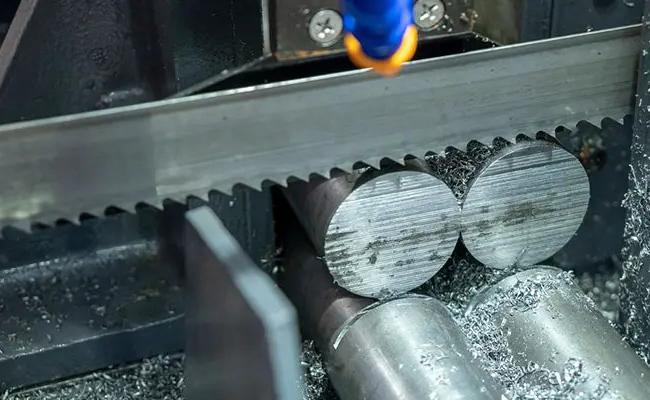

BS-5040 Horizontal Metal Cutting Bandsaw

Cutting Capacity :

A high-speed circular saw machine is a mechanical device that uses a high-speed rotating circular saw blade to cut materials such as metal, wood, and plastic. It is widely used in machinery manufacturing, automobiles, aerospace, construction, furniture, and other industries. Its core feature is fast and precise cutting through high speed, while also having high stability and durability. Choosing the right machine model and doing routine maintenance can significantly improve production efficiency and product quality.

Working principle of a high-speed circular saw machine:

1. Power drive: The motor drives the spindle to rotate the saw blade at a very high speed (usually 3000-6000 RPM, or even higher).

2. Cutting process: When the high-speed rotating saw blade contacts the workpiece, the sharp edge of the saw teeth is used to cut the material, while coolant or lubricant is used to reduce friction and heat.

3. Feeding method: The workpiece can be fed manually, hydraulically, or through a CNC system to achieve precise cutting.

Classification of high-speed circular saws:

1. By driving mode:

(1) Mechanical: driven by belt or gear, simple structure and low cost.

(2) Hydraulic: powered by hydraulic system, suitable for heavy-load cutting.

(3) Electric: directly driven by motor, high speed and fast response.

2. By cutting materials:

(1) Metal cutting circular saw: suitable for metal materials such as steel and aluminum, the saw blade is mostly made of carbide.

(2) Wood cutting circular saw: used for cutting furniture and building wood, the saw blade is thinner and the speed is lower.

(3) Plastic cutting circular saw: for plastic pipes, plates, etc., the saw blade design focuses on chip removal and heat dissipation.

3. By degree of automation:

(1) Manual: simple operation, suitable for small batch production.

(2) Semi-automatic: equipped with feeding device to reduce manual intervention.

(2) Fully automatic: automatic cutting is achieved through CNC system, with high precision and high efficiency.

Features of high-speed circular saw machine:

1. Fast cutting: high speed enables the saw blade to complete more cutting in unit time, greatly improving production efficiency.

2. High cutting accuracy: the saw blade runs smoothly, and the accuracy of ±0.1mm can be achieved with the CNC system.

3. Wide range of applications: can cut a variety of materials, including solid bars, pipes, profiles, etc.

4. Good safety performance: equipped with safety devices such as protective covers and emergency stop buttons to reduce operating risks.

5. Low maintenance cost: the saw blade has a long life, is easy to replace, and has a low overall maintenance cost.

Application areas of high-speed circular saw machine:

1. Metal processing: used for cutting steel pipes, aluminum profiles, stainless steel, etc., widely used in machinery manufacturing and automotive industries.

2. Wood processing: used for cutting solid wood, artificial boards, etc. in furniture manufacturing and door and window production.

3. Plastic processing: cutting PVC pipes, plastic profiles, etc., to meet the needs of the construction and packaging industries.

4. Aerospace: used for cutting high-strength alloy materials, requiring extremely high precision and stability.

Key points for purchasing high-speed circular saws:

1. Cutting requirements: Select the appropriate model according to the material type, thickness and cutting accuracy.

2. Power and speed: Ensure that the motor power and saw blade speed meet the cutting requirements.

3. Degree of automation: Select manual, semi-automatic or fully automatic models according to production scale and budget.

4. Safety performance: Check whether the protective devices, emergency stop functions, etc. are complete.

5. Brand and after-sales: Choose a well-known brand to ensure equipment quality and after-sales service.

Maintenance and maintenance of high-speed circular saws:

1. Regular inspection: Check the wear of the saw blade, motor temperature, lubrication system, etc.

2. Cleaning and maintenance: Clean the chips and coolant in time to prevent equipment clogging.

3. Saw blade replacement: Replace the saw blade regularly according to the usage to ensure cutting quality.

4. Lubrication and maintenance: Regularly add lubricating oil to bearings, gears and other components to extend the life of the equipment.

Development trend of high-speed circular saws:

1. Intelligence: Integrated CNC system and sensors to achieve automated cutting and fault warning.

2. Energy saving and environmental protection: Adopt exquisite motor and coolant recovery system to reduce energy consumption and pollution.

3. High precision: By optimizing saw blade design and control system, the cutting accuracy is further improved.

4. Multifunctionality: One device can be compatible with multiple materials and cutting methods, improving equipment utilization.

Cutting Capacity :

Cutting Capacity :