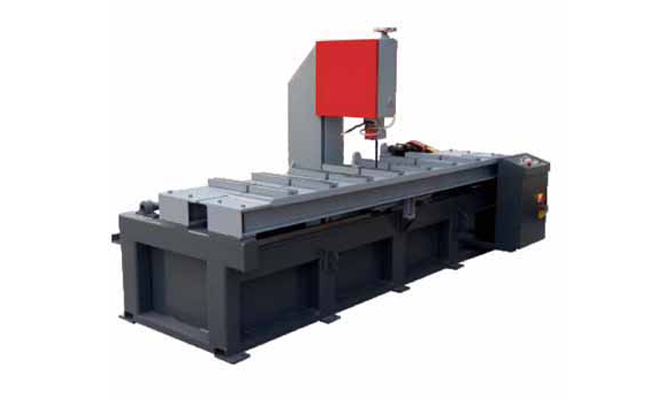

CL-200NC CL-260NC CL-300NC Circular saw machine

Cutting Capacity :

The metalworking band saw is the unsung hero of the fabrication shop, machine shop, and any environment where metal must be cut with efficiency and precision. Unlike abrasive cut-off saws or cold saws, a band saw uses a continuous, toothed metal band to make cuts with minimal kerf (width of the cut) and minimal waste material. Choosing the right one is a critical investment that impacts your productivity, operational costs, and cut quality for years to come. This guide will walk you through the essential considerations.

The first and most fundamental decision is the saw’s orientation: Horizontal or Vertical?

Horizontal Band Saws: These are the workhorses for cutting stock (bars, tubes, structural shapes) to length. The blade moves down through a fixed workpiece in a controlled, automated cycle. They are ideal for high-volume production cutting of the same material and size, offering excellent repeatability and unattended operation. They are less versatile for complex shapes.

Vertical Band Saws: These are the masters of versatility and contour cutting. The blade moves downward on a vertical plane, and the workpiece is manipulated by hand or with a feed table against the stationary blade. They are perfect for cutting curves, intricate shapes, notches, and trimming large sheets or fabricated parts. They are generally not used for high-volume production cutting of stock.

Key Selection Criteria:

Capacity: This is the maximum size of material the saw can accommodate.

For Horizontal Saws: Capacity is defined by the Round Capacity (e.g., 7″ round) and the Rectangular Capacity (e.g., 7″ x 12″). Always choose a saw with a capacity larger than your most common stock size.

For Vertical Saws: Capacity is defined by the Throat Distance (the distance from the blade to the column, determining the width of material you can cut, e.g., 20″) and the Maximum Height Under the Guide (determining the thickness, e.g., 18″).

Blade Speed (SFPM – Surface Feet Per Minute): Metal cutting requires specific blade speeds. Ferrous metals (steel, iron) require slower speeds, while non-ferrous metals (aluminum, brass) and plastics can be cut at much higher speeds. A saw with a variable speed control is invaluable for a shop that works with multiple materials.

Power & Construction: The motor horsepower (HP) determines the saw’s ability to power through tough materials without stalling. A more powerful motor (e.g., 2-5 HP for industrial models) is essential for cutting hard metals like stainless steel or large solid bars. Look for a heavily constructed, vibration-damping frame made of cast iron or welded steel for stability and accuracy.

Controls & Automation: Basic manual saws require operator intervention for every cut. For production environments, features like:

Automatic Feed: Applies consistent pressure for even blade wear.

Automatic Shut-Off: Stops the saw and retracts the blade once a cut is complete.

Programmable Logic Controls (PLC): Allows for storing multiple cutting programs for different materials and lengths.

These features drastically boost efficiency and reduce operator fatigue.

Understanding the categories of metal band saws will help you narrow down your choice based on your primary application.

1. Manual Horizontal Cut-off Saws:

The most basic type. The operator manually lowers the saw head to initiate the cut. These are low-cost and suitable for low-volume shops or maintenance departments where the saw is used infrequently.

2. Semi-Automatic & Fully Automatic Horizontal Cut-off Saws:

The standard for modern production. The operator clamps the material, sets the desired length (often with a measuring vise stop), and presses a button. The saw handles the entire cutting cycle—clamping, advancing, cutting, retracting, and stopping. Fully automatic models can be integrated with feeding systems for lights-out operation.

3. CNC Vertical Band Saws:

The pinnacle of precision contour cutting. These saws use computer numerical control to move the workpiece on an X-Y axis against the blade, allowing for the automated cutting of incredibly complex and identical shapes from plate metal. They are a game-changer for pattern cutting and precision fabrication.

4. Double Column (Gantry) Vertical Saws:

These massive vertical saws feature a blade suspended between two large columns, providing extreme stability and a huge throat capacity for cutting very large plates and sheets. They are essential for heavy fabrication and shipbuilding.

5. Portable Band Saws:

The handheld “sawzall-on-steroids” for metal. While not a stationary machine, they are a crucial type of metal-cutting band saw used for on-site work, cutting pipe, conduit, and stock in tight spaces. They can often be mounted in a stand to function as a small, makeshift vertical saw.

The saw itself is only half of the equation. The blade you choose is arguably more important for achieving a good cut. The key is matching the blade to the material.

1. Blade Material:

Carbon Steel: A general-purpose, economical blade for cutting soft metals like aluminum and mild steel. It dulls quickly on harder materials.

Bi-Metal (M42): The industry standard for industrial use. It features a flexible carbon steel back welded to a high-speed steel (HSS) tooth edge. This combination provides excellent fatigue resistance and cutting life, capable of handling hard and abrasive materials like stainless steel, tool steel, and exotic alloys.

Carbide Tipped: The premium option for extreme demands. Individual carbide tips are welded to the blade body. They stay sharper significantly longer than bi-metal when cutting abrasive materials (e.g., fiberglass, composites, superalloys, cast iron) but are also much more expensive and brittle.

2. Tooth Pitch (Teeth Per Inch – TPI):

This is critical for cut quality and blade life. The goal is to have 2-3 teeth in contact with the workpiece at all times.

Low TPI (2-3): Best for large cross-sections and soft materials (aluminum, thick stock). Provides large gullets (valleys between teeth) to clear chips efficiently.

Medium TPI (4-6): A versatile range for a mix of solid bars and structural shapes in steel.

High TPI (10-14+): Used for thin-walled tube, sheet metal, and small cross-sections. Prevents teeth from snagging and breaking.

3. Tooth Geometry:

Regular Tooth: A general-purpose geometry with evenly spaced teeth.

Hook Tooth: An aggressive tooth design with a deep gullet and positive rake angle for faster, softer cutting in materials like wood and non-ferrous metals.

Variable Pitch (Raker): Teeth are grouped in sets with varying pitch. This disrupts harmonic vibration, reducing noise and preventing “chatter” for smoother cuts in hard materials and large, vibrating sections.

Proper maintenance is non-negotiable for accuracy, blade life, and safety.

Break-In a New Blade: A new blade has ultra-sharp, brittle teeth. Run it at reduced speed and feed pressure for the first few cuts to gently wear the extreme sharpness off the tips. This prevents premature tooth chipper and extends its life.

Use the Correct Cutting Fluid: Flooding the blade with appropriate coolant is essential. It reduces heat (which anneals the teeth, making them soft), lubricates the cut, and flushes chips from the kerf. Use a quality soluble oil or synthetic coolant designed for metal sawing.

Track and Tension Correctly: Follow the manufacturer’s manual to set the proper blade tension and tracking. A loose blade will wander and produce inaccurate cuts, while an over-tensioned blade can fracture.

Keep Guides and Bearings Adjusted: The blade guides (often ceramic or carbide) and support bearings hold the blade rigidly in place directly behind the cut. Worn or improperly adjusted guides will cause poor cut quality and quickly ruin a blade.

Clean the Machine: Regularly remove chips and sludge from the tray, guides, and drive wheels. Built-up debris can affect performance and cause premature wear.

Read the Manual: Understand the specific controls and safety features of your machine.

Wear PPE: Always wear safety glasses, hearing protection, and gloves (though be cautious of rotating parts when handling material near the blade).

Secure the Workpiece: On a horizontal saw, ensure the vise is tightly clamped. On a vertical saw, use a push stick or jig when your hands must get near the blade.

Keep Hands Clear: Never place your hands in line with the blade’s cutting path.

Let the Saw Stop Completely: Before removing cut pieces, cleaning chips, or making adjustments, wait for the blade to come to a full stop.

Inspect Blades: Never install a damaged or cracked blade.

Investing time in selecting the right metal band saw pays massive dividends. A well-chosen, well-maintained band saw transforms a labor-intensive, messy cutting process into a clean, precise, and highly efficient operation. It reduces material waste, lowers consumable costs (through longer blade life), and frees up skilled labor for value-added tasks instead of just cutting stock. Whether you need the production prowess of an automatic horizontal saw or the artistic freedom of a vertical contour saw, the right band saw is the backbone of a modern metalworking facility.

| Feature / Type | Manual Horizontal | Automatic Horizontal | Standard Vertical | CNC Vertical | Portable |

|---|---|---|---|---|---|

| Primary Use | Cut-off stock to length | Production cut-off stock | Contour cutting, trimming | Precision contour shapes | On-site cut-off, utility |

| Best For | Low-volume shops, maintenance | High-volume production, repetition | Fabrication shops, prototypes | Aerospace, precision fab | Plumbing, electrical, field work |

| Capacity | 4″ – 10″ Round | 6″ – 20″+ Round | 18″ – 36″ Throat, 12″-20″ Height | Varies, often 30″+ Throat | 4″ – 5″ Round |

| Typical Power | 1 – 2 HP | 2 – 5 HP | 1.5 – 3 HP | 3 – 7.5 HP | 10-15 Amp Motor |

| Automation | None | High (Auto feed, cycle, stop) | Manual | Full CNC Programmable | None |

| Key Advantage | Low Cost | Efficiency, Repeatability | Versatility, Shape Cutting | Ultimate Precision, Automation | Portability, Low Cost |

| Key Limitation | Labor Intensive, Slow | Limited to straight cuts | Operator skill-dependent | High Cost, Programming | Low Accuracy, Limited Capacity |

| Approx. Price Range | $1,000 – $3,000 | $5,000 – $30,000+ | $3,000 – $15,000 | $25,000 – $100,000+ | $200 – $600 |

Cutting Capacity :

Cutting Capacity :