GZ4235 Automatic 14 Inch Bandsaw for Metal

Cutting Capacity :

In the modern processing industry, high-speed circular saw machine are highly respected for their high energy efficiency and accurate cutting capabilities. Whether in construction, furniture manufacturing or other industrial fields, the application range of high-speed circular saw machine is extremely wide. With its superior cutting performance and flexible application characteristics, high-speed circular saw machine can handle a variety of materials and become an indispensable tool in the industry. Next, let’s focus on what materials high-speed circular saw machine are suitable for, to help you better understand the application value of this tool in various processing needs.

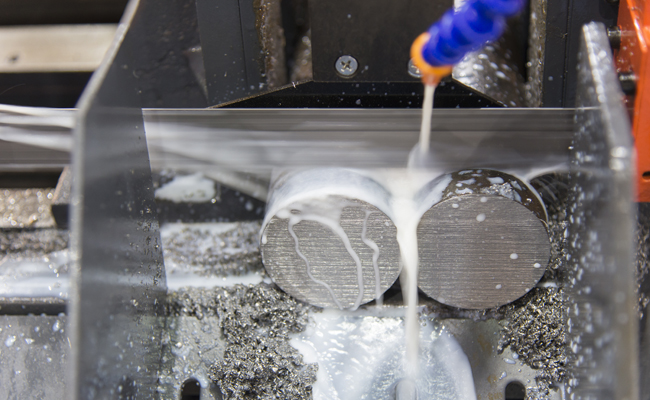

The band saw machine cutting the steel rod with the coolant

What materials are suitable for high-speed circular saw machine

high-speed circular saw machine are widely used in the field of wood cutting due to their high speed and high-precision cutting capabilities. As a common processing material, wood has strong adaptability. high-speed circular saw machine can easily handle a variety of wood, including solid wood, plywood, medium-density fiberboard (MDF) and particleboard. Whether it is used for wood cutting in building structures or fine processing of wood in furniture manufacturing, high-speed circular saw machine can provide the best cutting effect with their excellent performance. Its high speed and strong cutting force make the cutting of wood smoother and easier, reducing processing time and improving production efficiency.

In addition to wood, high-speed circular saw machine are also suitable for cutting a variety of metal materials. Including common metal materials such as aluminum alloy, copper, and steel, high-speed circular saw machine can achieve high-speed and accurate metal processing with their powerful cutting ability and professional design. The cutting requirements of metal materials are usually high, requiring the equipment to have strong cutting force and stable performance. high-speed circular saw machine are particularly outstanding in this regard. Their sharp circular saw blades and high-speed design make metal cutting more efficient and ensure the smoothness and precision of the cutting surface. In the fields of construction engineering, automobile manufacturing, metal processing, etc., high-speed circular saw machine provide a reliable solution for the processing of metal materials.

In addition, high-speed circular saw machine are also widely used in the cutting of plastics and composite materials. Plastic materials are widely used in various industrial and civilian products because of their light weight and easy processing. Composite materials play an important role in modern engineering because of their excellent performance and durability. high-speed circular saw machine can effectively process these materials and provide high-quality cutting results. When processing plastics, high-speed circular saw machine can reduce heat accumulation during cutting and avoid melting or deformation of plastics, thereby ensuring cutting accuracy and surface quality. For composite materials, the design of high-speed circular saw machine can cope with their complex structures, achieve accurate cutting, and meet high-standard processing requirements.

The application of high-speed circular saw machine is not limited to these common materials. Its flexible design and powerful cutting ability enable it to handle a variety of other materials. Whether it is concrete slabs for construction or high-strength materials for special purposes, high-speed circular saw machine can provide reliable cutting solutions with their technical advantages. Its wide range of applications and efficient performance make it an indispensable tool in various industrial applications.

In general, high-speed circular saw machine play an important role in many fields such as wood, metal, plastic and composite materials due to their excellent cutting performance and diverse application range. Its high-speed and high-precision cutting capabilities make the processing of various materials more efficient and accurate.

Cutting Capacity :

Cutting Capacity :