DLY-125W1 Portable Metalworking Band Saw Machine

Cutting Capacity :

As an indispensable cutting equipment in modern industrial manufacturing, CNC high-speed circular saws have been widely used in many fields such as metal processing and wood cutting due to their advantages such as high energy efficiency, accuracy and durability. However, how to use CNC high-speed circular saws correctly to give full play to their effectiveness and avoid unnecessary losses during operation is still a key content that many operators need to understand in depth. This article will focus on the tutorial and tips for using CNC high-speed circular saws to help users master the core operating essentials of the equipment, improve work efficiency, and extend the service life of the equipment.

Tutorial and tips for using CNC high-speed circular saws

Before operating a CNC high-speed circular saw, it is important to understand the basic structure and function of the equipment. CNC high-speed circular saws are usually composed of saw blades, mainframes, motors, CNC systems and other auxiliary components. The state of each component will directly affect the final cutting effect. Therefore, mastering the basic structure of the equipment is an important step to improve operating efficiency. For novice users, being familiar with the buttons, function keys and operation interface of the CNC panel of the CNC high-speed circular saw is the basis for ensuring safe operation and smooth cutting.

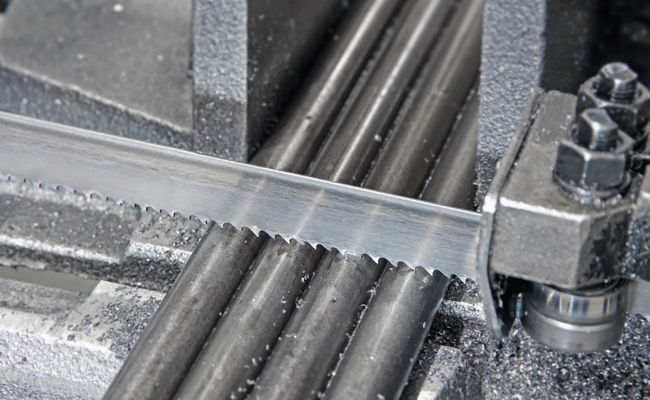

Next, when using the CNC high-speed circular saw machine in practice, choosing a suitable saw blade is one of the key steps. Depending on the different cutting materials, the choice of saw blade is particularly important. For example, for the cutting of metal materials, it is recommended to use carbide saw blades, which can ensure the accuracy and smoothness of the cutting, while for wood processing, high-speed steel saw blades or carbon steel saw blades should be selected, which can achieve better cutting results. Users should choose saw blades reasonably according to the characteristics of the material to be processed to avoid affecting the cutting quality due to the incompatibility of the saw blade.

In actual operation, adjusting the speed and feed speed of the saw blade is another important factor affecting the cutting quality of the CNC high-speed circular saw machine. Generally, when cutting harder materials, the speed of the saw blade should be appropriately reduced and the feed speed should be adjusted to prevent overheating and damage to the saw blade. On the contrary, for softer materials, the speed can be appropriately increased to improve the cutting efficiency. By reasonably adjusting the cutting parameters, the smoothness and accuracy of the cutting can be ensured, while reducing the wear of the saw blade and extending its service life.

After long-term use, the CNC high-speed circular saw machine will inevitably have the problem of saw blade wear. Therefore, it is very important to check the wear of the saw blade regularly. Usually, when the teeth of the saw blade are obviously blunt or the saw edge is rough, it needs to be replaced or re-sharpened in time. Operators should formulate regular maintenance plans according to the frequency of cutting tasks to ensure that the equipment is always in better working condition.

In addition to the selection and maintenance of saw blades, the correct setting of CNC parameters is also the key to improving the working efficiency of CNC high-speed circular saw machines. Users can set the corresponding cutting path and parameters in the CNC system according to the thickness, hardness and precision requirements of the processed materials. Accurate CNC programming can not only improve the accuracy of cutting, but also reduce material waste and improve the overall processing efficiency. Therefore, mastering the skills of CNC programming is a basic ability that every operator needs to have.

When operating a CNC high-speed circular saw machine, safety issues should not be ignored. Although the safety design of modern CNC equipment is quite complete, operators still need to follow the operating specifications of the equipment to ensure a clean and safe working environment. Before starting the machine each time, check whether the equipment is in normal condition, especially whether the saw blade is firmly installed and whether the motor is running smoothly. At the same time, during the cutting process, operators should wear necessary protective equipment, such as goggles and gloves, to avoid accidental injuries.

In addition to basic operating skills, there are also some practical tips in the use of CNC high-speed circular saw machines that can help users work more efficiently. For example, when cutting thinner metal plates, it is recommended to use coolant to assist in reducing the high temperature generated during the cutting process and avoiding material deformation. At the same time, reasonable planning of the cutting sequence can reduce material waste and improve the overall efficiency of cutting. When processing larger workpieces, it is recommended to use a clamp to fix the material to ensure the stability and accuracy of the cutting.

For enterprises, using CNC high-speed circular saw machines for batch processing is an effective way to improve production efficiency. By reasonably planning the production process and optimizing the use time of the equipment, enterprises can significantly increase production and reduce production costs. In addition, enterprises can upgrade or optimize the CNC system of CNC high-speed circular saw machines according to specific needs, so that they can better adapt to the production needs of the enterprise, thereby further improving the efficiency of the equipment.

In summary, the tutorials and tips for using CNC high-speed circular saw machines cover many aspects, from understanding the structure of the equipment, selecting and maintaining saw blades, setting CNC parameters to precautions in actual operation. By mastering these key knowledge and operating skills, users can not only effectively improve the working efficiency of the equipment, but also extend the service life of the equipment and maximize the potential of the CNC high-speed circular saw. In actual production, operators can also combine their own experience to continuously optimize the operating process to keep the equipment in a better working state, thereby achieving high-efficiency and safe cutting operations.

Cutting Capacity :

Cutting Capacity :