GZ4235 Automatic 14 Inch Bandsaw for Metal

Cutting Capacity :

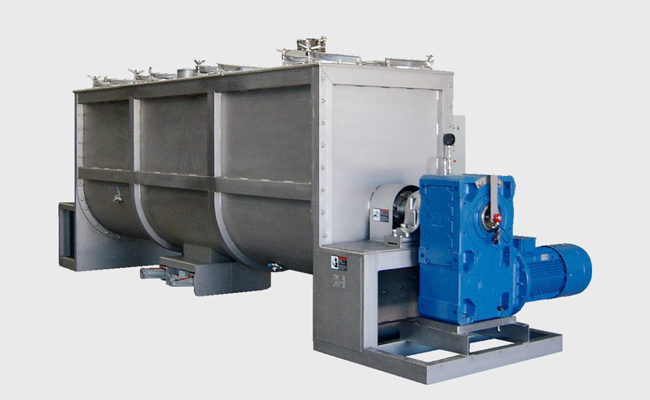

A Horizontal Ribbon Mixer is a type of industrial mixer used for blending dry powders, granules, and other solid materials uniformly. It consists of a horizontal trough (U-shaped or cylindrical) with a rotating shaft inside, fitted with ribbon-like agitators (inner and outer helical ribbons) that move materials in opposing directions to ensure thorough mixing.

Key Features:

Design:

Horizontal Orientation – Suitable for continuous or batch mixing.

Ribbon Blades – Inner ribbon pushes material outward, outer ribbon moves it inward, creating a cross-flow mixing action.

Construction Materials – Stainless steel (304/316), carbon steel, or special coatings for food, chemical, or pharmaceutical use.

Horizontal Ribbon Mixer Applications:

Food processing (spices, flour, additives)

Pharmaceuticals (powder blending)

Chemicals (fertilizers, pigments)

Animal feed production

Construction materials (cement, dry mortar)

Horizontal Ribbon Mixer Advantages:

High Mixing Efficiency – Uniform blending in short cycles.

Gentle Handling – Minimizes product degradation.

Easy to Clean & Maintain – Some models have hinged lids or openable ends.

Customizable – Options include jacketed (heating/cooling), vacuum, or gas-purged designs.

Limitations:

Not ideal for wet or sticky materials (may require paddles instead of ribbons).

Higher power consumption compared to some vertical mixers.

Horizontal Ribbon Mixer Working Principle:

Materials are loaded into the trough, and the rotating ribbons create a continuous folding and shearing action, ensuring homogeneous mixing. Discharge is typically through a bottom valve or sliding gate.

Cutting Capacity :

Cutting Capacity :