BS-100 Portable Bandsaw

Cutting Capacity :

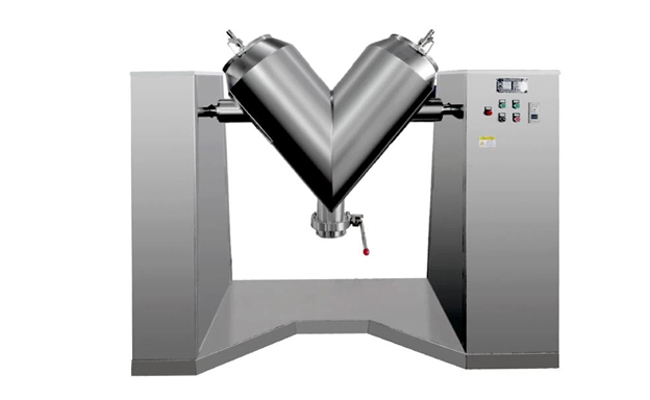

The V-type mixer is a widely popular and cost-effective dry powder mixing equipment, used for mixing dry powder materials. The mixture is gentle and uniform, suitable for both small-scale and large-scale production. It can be made of SS304 or SS316L stainless steel.

Powder feeding can be operated manually or used in conjunction with a vacuum feeder or screw conveyor to achieve automatic feeding. It is also possible to choose an internal booster rod for forced stirring.

V-type mixers have become the basic and essential equipment in most dry powder processing plants and are widely used in the pharmaceutical, chemical and food industries.

1. What is a V-type dry powder mixer?

The V-type mixer is an efficient asymmetric powder mixing equipment that can mix dry powder and granular materials. This powder mixer is suitable for the mixing of various dry materials in industries such as chemical engineering, food, pharmaceuticals, feed, ceramics and metallurgy.

The V-type mixer adopts a unique mixing cylinder structure to ensure uniform mixing, high efficiency and no material accumulation. This machine has a simple structure and is easy to operate. Its outer surface and components in contact with materials are all made of high-quality stainless steel, featuring an exquisite appearance and being easy to maintain and clean.

2. How is a V-type mixer manufactured?

The V-type mixer is mainly composed of a V-type mixing barrel, a base, a transmission system, an electrical system, etc. It adopts two asymmetric barrel structures and gravity stirring. The materials continuously aggregate and disperse in the V-shaped mixing tank. Usually, it takes 5 to 15 minutes to achieve thorough mixing of two or more powdered or granular materials, with a mixing uniformity of over 99%. Both the inner and outer walls of the V-shaped mixing barrel have been precisely polished, with a smooth and flat surface and no dead corners, making it easy to clean.

1) High uniformity of mixing: The V-type mixer adopts a structure of two half-barrels of unequal lengths. Due to the time difference of material flow in the V-shaped mixing barrels, the mixing efficiency is high and the uniformity of mixing is high.

2) No cross-contamination: There are no dead corners inside the barrel and in contact with the materials. The mixing process is gentle, preventing segregation and ensuring complete discharge without residue, thus avoiding cross-contamination.

3) Long service life: The V-type mixer is made of high-quality stainless steel, which is rust-proof, corrosion-proof, stable and durable.

3. What is the working principle of the V-type dry powder mixer?

One end of the V-type mixer is equipped with a motor and a reducer. The power of the motor is transmitted to the reducer through a belt, and then the reducer transmits the power to the V-shaped mixing container through a sprocket. This causes the V-shaped mixing container to keep rotating, driving the materials inside the container to move up, down, left and right for mixing.

In addition, the V-type mixer can be designed with a booster rod inside the V-type mixing container. It is particularly suitable for mixing fine powders, materials prone to caking or various powdered materials with high moisture content. Even if the addition amount is very small (referring to the mixture of a small amount of ingredients), the best mixing effect can still be achieved.

This machine has a reasonable and simple structure, with easy operation steps and convenient loading and unloading of materials (manual or vacuum feeding, achieving dust-free operation). The V-shaped mixing container is made of stainless steel, highly polished and easy to clean. V-type mixers and double-cone mixers have become one of the essential equipment for most powder processing enterprises.

4. What is the purpose of the V-type mixer?

The V-type powder mixer is suitable for mixing dry powder materials with good fluidity and small physical property differences, as well as materials with low requirements for mixing uniformity but short mixing time. As the materials flow smoothly in the V-shaped mixing container, their original shape will not be damaged. Therefore, the V-type mixer is also suitable for mixing fragile and easily worn granular materials. It is also widely used for mixing fine powders, granules and materials containing a certain amount of moisture, and is widely applied in the pharmaceutical, chemical, food and other industries.

5. Precautions for the Use of V-type mixer

Before use, please conduct a no-load test run. Before the trial operation, please check the firmness of all connecting parts of the V-type mixer, the lubricating oil level in the reducer and the integrity of the electrical equipment. Then, turn off the main switch, connect the power supply, and conduct a no-load test run.

2) Installation: Place the V-shaped mixer on a stable ground, install the machine feet, and level it to ensure smooth operation of the machine.

3) Before use, please lubricate the necessary components, then conduct a no-load test run to check if the fasteners are loose, if the electrical functions are normal, and if the machine operates normally. If any abnormalities are found, please carry out maintenance and adjustment.

4) Rotate the feeding port upwards to open the feeding cover for feeding. The feed quantity must not exceed the specified amount. Then, close the feed cover and start the machine. During operation, if any abnormality is detected, the machine must be stopped for inspection.

5) It is strictly prohibited to mix multiple batches of granular drugs together, nor is it allowed to produce different varieties of drugs or foods on the same production line. GMP standards must be adhered to.

6) When changing varieties, the inside and outside of the V-shaped mixing container must be thoroughly cleaned and disinfected.

6. How to operate a V-type mixer for dry powder mixing production?

The usage method of the V-type mixer is as follows:

First, open the feeding port of the mixer. According to the process requirements, pour the specified amount of material into the V-shaped mixing container. After feeding, to prevent the material from flowing out during the mixing process, the feeding port must be closed and locked, and it should be confirmed that the discharging port is closed.

Next comes the operation of the machine. Connect the main power supply, rotate the emergency stop button to the left, and press the switch button to start the mixer. (If the V-type mixer is equipped with a frequency converter, please adjust the motor speed within the speed range specified by the process.) According to the process requirements, after the stirring reaches the specified time, stop the operation. When the machine is shut down, the discharge port of the mixer should face the ground. After completion, the power supply should be cut off.

Finally, unloading: Open the discharge port of the V-type mixer and place the designated unloading container below the discharge port until all the materials in the V-type mixer container are discharged.

7. How to maintain a V-type mixer?

The V-type mixer is suitable for an ambient temperature range of -5 to 40°C and a relative humidity of less than 90%. It should be stored in a well-ventilated, dry and clean place.

2) Do not let children come into contact with the V-type mixer to avoid accidents.

3) The lubrication of the reducer should be carried out by oil-immersed lubrication. The oil level must be maintained at the specified mark and the oil quality must be kept clean. If used frequently, the lubricating oil should be replaced every three months. When replacing, the reducer should be cleaned and new oil added.

4) The electrical control components of the V-type mixer should be kept clean and sensitive. If any faults are found, they should be repaired in time.

5) After each use or when the V-type mixer is not in use, the remaining materials in the V-type mixing bucket should be emptied, and the powder remaining on the machine parts should be brushed off with a brush. If the machine is not used for a long time, the V-type mixer must be thoroughly cleaned and covered with a cloth to prevent dust.

When disassembling the V-shaped mixing drum, handle it with care to avoid deformation or damage.

7) Regularly inspect the components, 1-2 times a month, to check the flexibility and wear of moving parts such as the power shaft, transmission, and reducer. If any defects are found, they should be repaired in time to ensure the normal operation of the V-type mixer.

Cutting Capacity :

Cutting Capacity :