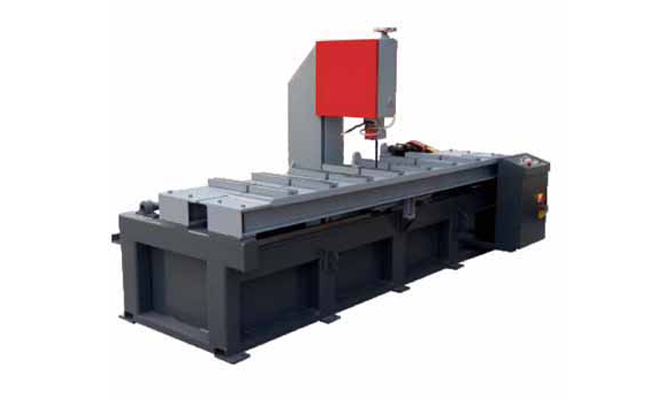

TBK-4228 Double Column Band Saw

Cutting Capacity :

Industrial metal bandsaws are essential for cutting various types of metal in manufacturing, fabrication, and construction. They come in different configurations based on their operation, cutting orientation, and application. Here are the main types:

1. By Operation Type

A. Manual Bandsaws

Operated by hand; the user controls the feed rate and cutting process.

Best for small workshops or low-volume cutting.

Example: Basic horizontal or vertical manual bandsaws.

B. Semi-Automatic Bandsaws

Combine manual loading with automated cutting cycles.

Often include hydraulic or pneumatic feed controls.

Example: Semi-automatic horizontal bandsaws with auto-feed.

C. Fully Automatic Bandsaws

Fully automated loading, cutting, and unloading.

Used in high-production environments.

Example: CNC bandsaws with robotic part handling.

2. By Cutting Orientation

A. Horizontal Bandsaws

Blade moves horizontally, ideal for long stock and bar cutting.

Often used for cutting metal bars, pipes, and structural materials.

Can be manual, semi-automatic, or fully automatic.

Subtypes:

Pivot (Swivel) Frame – The saw head pivots for angled cuts.

Dual Column – More rigid, used for heavy-duty cutting.

B. Vertical Bandsaws

Blade moves vertically, allowing for more intricate cuts.

Used for contour cutting, shaping, and detailed work.

Common in fabrication shops for custom metalwork.

Subtypes:

Fixed Head – Standard vertical bandsaw.

Tilting Head – Allows for bevel cuts.

C. Dual (Combination) Bandsaws

Can switch between horizontal and vertical operation.

Offers flexibility for different cutting needs.

3. By Application & Specialization

A. Cut-Off Bandsaws

Designed for straight cuts on metal stock.

Mostly horizontal models.

B. Contour Bandsaws

Used for curved or complex shapes.

Typically vertical bandsaws.

C. Structural / Beam Bandsaws

Heavy-duty saws for cutting large beams, pipes, and structural steel.

Often have high blade tension and powerful motors.

D. Portable Bandsaws

Handheld or benchtop models for on-site or small-scale cutting.

Example: Milwaukee Deep Cut or DeWalt portable bandsaws.

E. Cold Saws (Alternative to Bandsaws)

Use a circular blade with coolant for precise cuts.

Not technically a bandsaw but sometimes used for similar applications.

4. By Feed Mechanism

A. Gravity-Feed Bandsaws

Uses the weight of the saw head to apply cutting pressure.

Common in manual horizontal bandsaws.

B. Hydraulic-Feed Bandsaws

Hydraulic system controls the downfeed for consistent cutting.

Used in industrial semi-automatic and automatic saws.

C. Servo-Driven Bandsaws

Precision-controlled feed via servo motors (common in CNC bandsaws).

5. By Blade Speed & Cutting Method

A. Bi-Metal Bandsaws

Use high-speed steel (HSS) edge welded to a flexible alloy backing.

General-purpose metal cutting.

B. Carbide-Tipped Bandsaws

For cutting hard metals like titanium, Inconel, and tool steel.

Longer blade life but more expensive.

C. Friction Cutting Bandsaws

High-speed blades that melt through metal (used for fast cuts in thin materials).

Choosing the right industrial metal bandsaw depends on:

Material type (steel, aluminum, hardened alloys).

Cutting needs (straight cuts, contours, high production).

Workspace & automation level (manual vs. CNC).

Cutting Capacity :

Cutting Capacity :