CH-280HA Fully Automatic Band Saw

Cutting Capacity :

Horizontal band saw machine is a high-efficiency cutting equipment, widely used in the processing of wood, metal and other hard materials. With its horizontal design structure, horizontal band saw machine is particularly suitable for precise cutting and mass production of long strip materials, and plays an important role in modern manufacturing industry.

1. Working principle of horizontal band saw machine

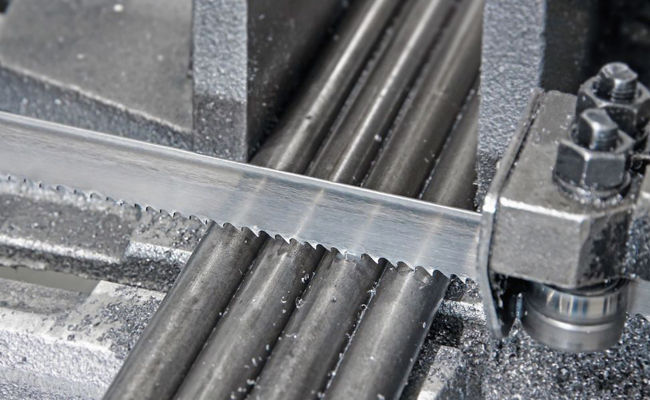

Horizontal band saw machine drives the saw belt to run continuously in a cycle through the motor, and the saw belt passes around the guide wheels on both sides to cut the material on the horizontal plane. The material is placed on the workbench or support frame and cut with the rotation of the saw belt.

The teeth of the saw belt are close to the surface of the material, and the cutting is completed by the friction between the teeth and the material. According to different materials and processing requirements, the feed speed, tension and cutting angle of the saw belt can be adjusted. Its unique horizontal structure and large workpiece carrying capacity make the horizontal band saw machine an ideal equipment for metal sawing, wood cross-cutting and building material cutting.

2. Operating procedures for horizontal band saws

1. Preparation

Before operating the horizontal band saw, necessary inspections and preparations need to be performed to ensure that the machine is in good condition.

Saw band inspection: Check whether the saw band is worn, missing teeth or broken. If there is a problem, it should be replaced in time.

Guide wheel and tension adjustment: Adjust the tension of the saw band to ensure that it is tight but not over-tightened, and check whether the guide wheel rotates smoothly.

Power supply and lubrication inspection: Ensure that the power supply is connected normally, and check whether the guide rails and transmission parts are well lubricated to reduce friction loss.

2. Material fixing and parameter setting

Fix the material: Place the material to be cut firmly on the workbench or support frame, and fix it with a clamp to prevent the workpiece from moving during cutting.

Cutting parameter setting: Set the cutting speed, saw band feed rate and cutting angle according to the type, thickness and processing requirements of the material to ensure better cutting effect.

3. Start and cutting operation

Start the machine: After confirming that all safety devices are in place, turn on the power to start the band saw.

Smooth feeding: Feed the material slowly into the saw band during cutting to avoid sudden push that may cause the saw band to break or the workpiece to shift.

Monitor cutting status: Observe the operation and cutting status of the saw band at any time, and stop the machine for inspection in time if abnormalities are found to avoid damage to the equipment or affect the cutting accuracy.

4. Processing after cutting

Shutdown and cleaning: After cutting, turn off the power and wait for the saw band to stop completely before removing the workpiece.

Debris cleaning: Clean the sawdust and waste on the workbench and the machine body to ensure that the machine is clean and ready for the next operation.

Maintenance and inspection: Regularly check the wear of the saw band and guide rails, and perform necessary maintenance and replacement to keep the equipment in better condition.

3. Main advantages of horizontal band saw machine

1. Suitable for cutting large workpieces and long materials

The horizontal design of the horizontal band saw machine enables it to easily handle long materials such as steel pipes, aluminum, wood, etc. Even large workpieces can be accurately cut on their stable support structure.

2. High-efficiency and stable continuous cutting

The band saw machine adopts the continuous circulation movement of the saw band, and the cutting process is smooth and low-noise. Compared with traditional sawing machines, it reduces the time of frequent startup and shutdown, improves production efficiency, and is especially suitable for mass production.

3. High cutting accuracy

The horizontal band saw machine is equipped with an accurate guide device and a tension control system to ensure that the saw band will not deviate during the cutting process, providing a high-precision cutting effect. Whether it is the precision processing of metal materials or the complex shape cutting of wood, it can achieve the ideal quality standard.

4. High safety

Modern horizontal band saw machines are equipped with multiple safety devices, such as emergency stop buttons, saw band guards and workpiece clamps, which can effectively reduce operating risks. In addition, the horizontal structure makes the material fixation more stable and reduces the safety hazards caused by loose materials.

5. Wide range of applications

In addition to common wood and metal materials, horizontal band saw machines can also be used to cut a variety of materials such as plastics and composite materials, and are widely used in construction, furniture manufacturing, automotive parts processing and other industries.

6. Simple maintenance and long service life

The structural design of the horizontal band saw machine is simple and easy to maintain on a daily basis. You only need to regularly check the tension of the saw band, clean the guide rails and lubricate key components to ensure long-term high-efficiency operation of the equipment and reduce maintenance costs.

4. Application fields of horizontal band saw machines

1. Metal processing: In the fields of metal processing such as steel and aluminum, horizontal band saw machines are widely used to cut long strip materials such as steel pipes, H-shaped steel, etc., to ensure high-efficiency cutting and accurate dimensions.

2. Wood processing: The wood industry often uses horizontal band saw machines for cross-cutting, cutting and splicing, which is suitable for furniture manufacturing and woodworking decoration.

3. Construction industry: Horizontal band saw machines can be used to cut building materials such as stone, composite panels, etc., to improve the efficiency and quality of construction.

4. Automobile manufacturing: In the process of automobile parts processing, horizontal band saw machines are used to cut a variety of hard materials to provide high-precision parts support for vehicle production.

Horizontal band saws have become an important tool in the manufacturing and construction industries due to their excellent cutting performance and flexible application scenarios. Their energy-efficient cutting capabilities, excellent stability and safety make them popular in mass production and precision machining. Mastering the correct operating procedures and doing a good job of daily maintenance can give full play to the advantages of horizontal band saws, improve production efficiency and reduce operating costs. Whether in the field of metal processing or wood cutting, horizontal band saws are cutting equipment that users can trust.

Cutting Capacity :

Cutting Capacity :