Selecting the right band saw machine is a critical decision for any metalworking, woodworking, or fabrication shop. The correct choice enhances productivity, improves cut quality, and maximizes return on investment, while the wrong one can lead to inefficiency, poor results, and wasted material. This guide provides a detailed, structured approach to evaluating your needs and choosing the optimal band saw for your specific applications.

1. Understanding the Core Decision: Horizontal vs. Vertical Orientation

The most fundamental choice in band saw selection is between a horizontal and a vertical configuration. This primary distinction dictates the machine’s capabilities, workflow, and ideal use cases.

-

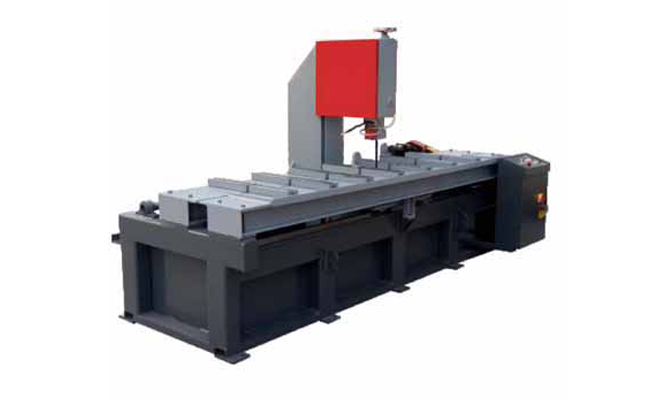

Horizontal Band Saws: The blade is oriented horizontally, and the cutting head (or the material) moves downward in a controlled arc or straight line to perform the cut. They are primarily designed for cut-off or sizing operations—cutting stock material like bars, tubes, and structural shapes to a specific length.

-

Vertical Band Saws: The blade runs vertically, and the workpiece is manually or CNC-fed into the stationary blade. They are designed for contouring, shaping, notching, and intricate cuts, in addition to straight cut-off tasks.

The following sections break down the critical factors that will guide you toward the correct type and specification.

2. Primary Factors to Consider When Choosing a Band Saw

Your decision should be driven by a clear analysis of your operational requirements. The following factors are the pillars of a sound investment.

2.1 Material Type and Size

The physical properties of the material you cut most frequently are the most important starting point.

2.2 Cut Complexity and Function

What kind of cuts will you be performing? This factor most clearly separates horizontal and vertical saws.

-

Straight Cut-Off / Sizing: If 95% of your work involves cutting stock to length, a horizontal band saw is the most efficient and accurate choice.

-

Contour Cutting, Notching, and Angled Cuts: If you need to cut curves, shapes, or complex profiles, a vertical band saw is the only option.

-

Combination of Both: Some shops start with a vertical band saw for its versatility. However, for high-volume straight cutting, this is inefficient. A common solution is to have both, or to opt for a CNC Vertical Band Saw which can automate complex profiles and straight cuts.

2.3 Production Volume and Automation Needs

How many cuts per shift or per day do you need to make?

-

Low Volume / Prototyping: Manual machines (both horizontal and vertical) are cost-effective and sufficient.

-

Medium to High Volume: Semi-automatic and automatic features become critical.

-

Horizontal Saws: Look for features like automatic stock indexing, programmable length stops, and bundle cutting. A machine with a CNC controller can store multiple cutting programs for different jobs, drastically reducing setup time and operator error.

-

Vertical Saws: For production contouring, a CNC Vertical Band Saw is essential. It uses a programmed path to guide the blade, ensuring repeatability and high throughput on complex parts.

-

Lights-Out Operation: Fully automated systems with material loading robots and conveyor systems are available for high-production environments. This is almost exclusively the domain of horizontal cut-off saws.

2.4 Available Space and Shop Floor Layout

The machine’s footprint and workflow integration are practical constraints.

-

Horizontal Band Saws: Typically have a longer footprint to accommodate the feeding of long stock. They are often dedicated stations in a material preparation area.

-

Vertical Band Saws: Have a smaller footprint but require ample space around the machine for the operator to maneuver large workpieces.

2.5 Operator Skill Level

The complexity of operation varies significantly.

-

Manual Vertical Band Saws: Require a high degree of operator skill to guide the workpiece accurately along a layout line for quality results.

-

Manual Horizontal Band Saws: Require less skill for basic operation (loading material, starting cycle) but still need training for proper blade selection, speed/feed setting, and machine maintenance.

-

CNC Band Saws (Both Types): Reduce the dependency on operator skill for cut quality. The operator’s role shifts to loading/unloading and programming, which requires a different skillset.

2.6 Budget and Total Cost of Ownership

Consider not only the initial purchase price but also long-term costs.

-

Initial Investment: Vertical band saws are generally less expensive than horizontal saws of similar capacity. CNC options add significant cost.

-

Operational Costs: Factor in the cost of blades, coolant, and maintenance. A well-built machine may have a higher upfront cost but lower long-term maintenance and downtime.

-

Efficiency Gains: An automated horizontal saw may have a high price tag, but the labor savings and material optimization can lead to a rapid return on investment (ROI) in a production setting.

3. Horizontal vs. Vertical Band Saws: A Detailed Comparison Table

This table provides a clear, at-a-glance comparison to solidify the distinctions.

4. Making the Final Decision: Application-Based Scenarios

To translate the factors above into a final decision, consider these common scenarios:

-

Scenario A: Structural Steel Fabrication Shop

-

Needs: Cutting wide-flange beams, angle iron, and channel to length. High volume of straight cuts.

-

Recommended Choice: A large-capacity Horizontal Band Saw with a mitering capability (0-45° or more) to cut angles. A semi-automatic model with a power vise and stock stop will drastically improve throughput.

-

Scenario B: Custom Knife Maker or Metal Artisan

-

Needs: Cutting intricate profiles from plate steel, notching, and shaping.

-

Recommended Choice: A robust Vertical Band Saw (manual or CNC, depending on volume and repeatability needs). A variable speed control is essential to dial in the correct SFPM for different metals.

-

Scenario C: General Maintenance and Repair Shop

-

Needs: Versatility to handle a wide variety of tasks—cutting pipe, bar stock, and occasionally making a repair part with a non-standard shape.

-

Recommended Choice: A Vertical Band Saw is often the best “one-and-done” machine for its flexibility. It can perform straight cut-offs (though less efficiently than a horizontal) and handle contouring tasks when needed.

-

Scenario D: High-Production Automotive Component Manufacturer

-

Needs: Unattended cutting of thousands of solid steel bars per shift with extreme consistency.

-

Recommended Choice: A fully automated CNC Horizontal Band Saw system integrated with a bar feeder and conveyor for finished parts, enabling lights-out operation.

5. Conclusion

There is no universal “best” band saw; there is only the best band saw for your specific application. By systematically evaluating the Material Type, Cut Complexity, Production Volume, and your operational constraints, you can move beyond the horizontal vs. vertical dilemma and specify a machine that will serve as a productive and profitable asset for years to come. Always consult with reputable manufacturers and dealers, and if possible, arrange a demonstration with your own material to validate the machine’s performance before purchasing.