GZL Series Dry Granulating Set

- Model:GZL Series

- Categories:Granulator Series

- Email : contact@he-mu.com

| Item / Data / Model | GZL-240 | GZL-360 | GZL-450 |

|---|---|---|---|

| Diameter of roll (mm) | Φ240 | Φ360 | Φ450 |

| Width of roll (mm) | 80-160 | 180-500 | 220-1000 |

| Revolution of roll (rpm) | 15, 20, 26, 32 | 14, 18, 24, 30 | 10-25 |

| Max. pressure of roll (MPa) | 120 | 160 | 210 |

| Max. thickness of pill (mm) | 4 | 8 | 8 |

| Capacity of pill (kg/h) | 200-500 | 500-3000 | 800-5000 |

| Diameter of finished pill (mm) | 0.5-6 | 0.5-8 | 0.5-6 |

| Capacity of finished product (kg/h) | 160-400 | 400-2400 | 680-4000 |

| Power of main machine (kW) | 7.5 | 22-37 | 45 |

| Total power (kW) | 20 | 50 | 80 |

| Overall dimension (L×W×H) (mm) | 1500×1300×5000 | 2000×2000×9000 | 2500×2500×10000 |

| Weight (t) | 6 | 10 | 13 |

Description

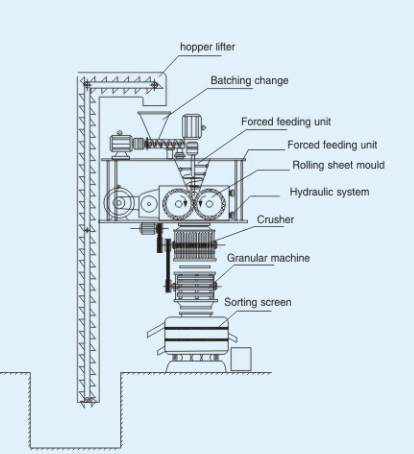

1. Adopts dry pressing technology to pressure material with moisture contentof lower than 10% into sheets, and it’s processed into required particlesthrough breaking,granules treaming and screening process.

2. The material is pressed by exterior force, and passes through the gapbetween the two rollers which are rotating in different directions. andthen it is pressded into sheets. The mass density of material mightincrease 1.5-3 times, so to achieve required strength.

Principle

1. Dry material powder is fed from the top of the equipment, de-air,screw-pre-press, enter into the gap between the two rollers that are rotating inopposite directions. The pressed material falls down because of surfacetension and gravity when passes through pressing section. The noddlesshaped material then enters into breaking machine, been smashed byrotating knife. The smashed material enters into granulator, and then theparticles and part of powder material enters into sieve by the rolling knifeand then the product is separated. The product up to standard will beconveyed to product silo by conveyor; the material under the sieve should befed back and should be pressed again, The pressure might adjust by thehydraulic oil cylinder according the requirements of granulation.

2. Sheet, bar and other shape of product might be procured by choosethe relative shape of the grooves on the surface of the roller.

Features

1. The material is forced and to be pressed by mechanical force.without any additiona! ingredients.so to ensure purity.

2. The dry material is made into granules directly, no need any furtherdrying process. So it’s good for product process.

3. The strength of the particles are high, the mass density is increasedmore apparently compare to other method of granulation. lt’s especiallyapplicable for to increase the mass density of product.

4. The pollution of enviroment is controlled, the wasted powder isreduced, the packaging fee is decreased and the product is easier intransportation.

5. The structure is compact, the maintenance is convenient, the operationis simple, the process is short, the energy consumption is low, theefficiency is high, the probablity of fault is low, the application range iswide, and the pressure of roller might be adjusted freely according to theproperty of material.

6. The material feeding adopts non-step inverter control, the automationlevel is hiah, One operation miah control multi-units of machine. Thelabor intensity is low, and the the machine might run continuously in longtime.

7. Adopt high quality alloy,stainless steel, Ti, Cr and other metal fordriving parts,the wear-resistance,cossive-resistance, thermo-resistance andpressure-resistance is highly increased. The service life is long.

Application

Oil &chemical

Metalic power

Finechemical

Medicine

Fertilizer

Agrochemical

Foodstuff

Biosynthesis

Mine, Coal mine