FLP Series Fluid-bed granulator/pelletor/coater

- Model:FLP Series

- Categories:Granulator Series

- Email : contact@he-mu.com

| Item | Model | |||||||||

| Name | Unit | FLP-10 | FLP-15 | FLP-20 | FLP-30 | FLP-45 | FLP-60 | FLP-90 | FLP-120 | |

| Dia of container | mm | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1400 | 1500 | |

| Productive capacity | kg/batch | 2.5–10 | 3–15 | 5–20 | 7.5–30 | 10–45 | 15–60 | 20–90 | 30–120 | |

| Power of fan | kw | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 18.5 | |

| Steam | Pressure | Mpa | 0.4–0.6 | |||||||

| Consumption | Kg/h | 35 | 42 | 47 | 60 | 140 | 160 | 180 | 240 | |

| Compressed air | Pressure | Mpa | 0.6 | |||||||

| Consumption | m³/min | 0.6 | 0.6 | 0.6 | 0.9 | 0.9 | 1.1 | 1.3 | 1.5 | |

| Noise | dB | ≤75 | ||||||||

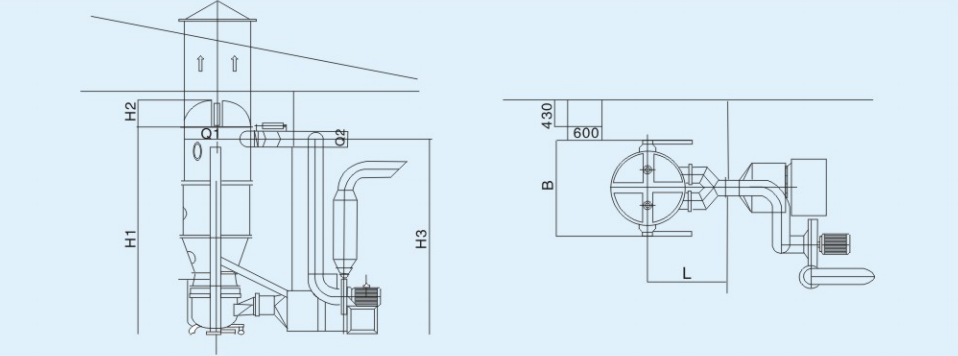

| Installation size | H₁ (mm) | 2790 | 3350 | 3650 | 3720 | 3720 | 3850 | 3950 | 4190 | |

| H₂ (mm) | 340 | 490 | 540 | 590 | 640 | 690 | 740 | 790 | ||

| H₃ (mm) | 2570 | 3130 | 3430 | 3500 | 3500 | 3630 | 3720 | 3975 | ||

| Φ₁ (mm) | 700 | 1000 | 1000 | 1200 | 1300 | 1400 | 1500 | 1600 | ||

| Φ₂ (mm) | 250 | 250 | 250 | 280 | 280 | 280 | 280 | 315 | ||

| L (mm) | 1250 | 1400 | 1450 | 1500 | 1550 | 1600 | 1650 | 1700 | ||

| B₁ (mm) | 1160 | 1460 | 1560 | 1600 | 1760 | 1860 | 1960 | 2060 | ||

| B₂ (mm) | 1860 | 2460 | 2660 | 2860 | 3060 | 3260 | 3460 | 3660 | ||

Description

FLP Granulator/Coater/Pelleter is multi-function equipmentintegrated spray drying-granulating-centrifugal spray coating-fluid coating-drying in one body. The machine combines variousprocess operations.Particularly it is suitable for granulatingpelleting and coating of various varieties in pharmaceutiCaindustry,foodstuff industtry and chemical industry etc.

Features

1. Multi-function such as granulating, pelleting, coating in one machine.

2. Powder material granulating.

3. Powder material coating.

4. Powder material pelleting.

5. Chinese medicine spray drying, granulating and coating.

6. MMake 1 0-30 meshes big granule.

7. Film coating of Powder, granules and pellets, entericrelease, slow andcontrol release coating.

8. Taste masking, odor, moisture-proof, anti-oxidation, prevent water,heat insulation, coloration, and sepration coating.

9. Powder, granule, agglomerate material drying.

Fluid beds for choose

Sketch of Flow Chart