GHL Series High Speed Mixing Granulator

- Model:GHL Series

- Categories:Granulator Series

- Email : contact@he-mu.com

| Name | Specification | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

|---|---|---|---|---|---|---|---|---|

| Capacity (L) | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Output (kg/batch) | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| Mixing speed (r.p.m) | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Mixing power (kw) | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| Cutting speed (r.p.m) | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

| Cutting power (kw) | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| Amount of compressed air (m³/min) | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

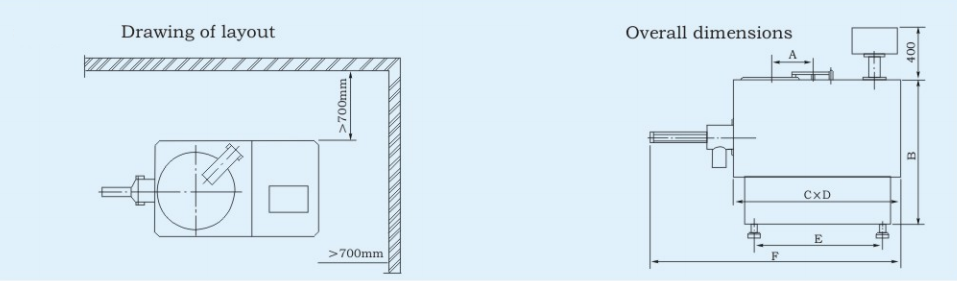

| Type | A (mm) | B (mm) | C×D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|

| 10 | 270 | 750 | 1000×650 | 745 | 1350 |

| 50 | 320 | 950 | 1250×800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350×800 | 1050 | 1750 |

| 200 | 500 | 1100 | 1650×940 | 1450 | 2050 |

| 250 | 500 | 1160 | 1650×940 | 1400 | 2260 |

| 300 | 550 | 1200 | 1700×1000 | 1400 | 2310 |

| 400 | 670 | 1300 | 1860×1100 | 1550 | 2410 |

| 600 | 750 | 1500 | 2000×1230 | 1750 | 2610 |

Principle

The powder raw material and adhesive in a cylinder are mixed fully at thebottom to turn into a humid soft material. Then it is crushed at a highspeed and become uniform granules.

Features

1. The machine adapts a practical horizontal cylinder structure.

2. The driving shaft is equipped with inflatable seal. While washing.

the air can be replaced by water.

3. Fluidized granulating processed is used and the final granules arequite round with high fluidity.

4. Compared with traditional technique, this type of machine canreduce 25% of adhesive and also shorten the drying time.

5. For each batch of material, with 2 minutes’ dry mixing and 1-4 minutes’ granulating, the efficiency is 4-5 times higher than that of traditional technique.

6. Dry mixing, wet mixing and granulating are finished inside thesame sealed container,which is in conformity with therequirements of “GMP”.