DWD Series Dryer for Vegetable Dehydration

- Model:DWD Series

- Categories:Dryer Series

- Email : contact@he-mu.com

Description

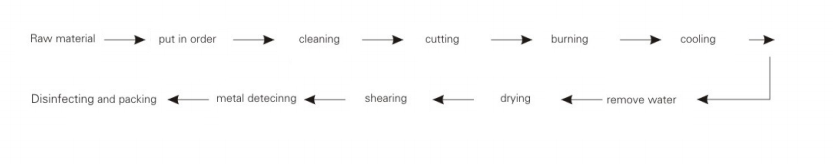

DVD Series Dryer for Vegetable Dehydration is a specialequipment researched and developed on the basis of traditional net belt dryer, it has strongelpertinency,practicability and high efficiency of energy.is wide used for all kinds of vegetables dehydration such as garlic, cushaw, giantarum, whiteturnip, yam, bamboo shoot, etc at diferent region and season, our factory has more than 50 of customers and more 80 of production line in operation. Ourfactory is an enterprise with the richest experience to manufaclure diyer for vegetables dehydration. The technicians of our factony cary out atter salessenvice for customers allthe year round and help customers to debug and produce. There fore they have got first-hand practical data and combineddomestic and abroad advanced technology and improved and perfected the equipment. Til the third generation. DWD series dyer for vegetablesdehydration has been developed. we are making advanced productive equipment for customers. according to the characteristics of raw materias be driedand the process reaurements of customers and combined the accumulated experence for more than ten years, we have made the most suitable and thedryer for vegetables dehydration to supply customers

Features

Its dry area. air pressure, air amoun., dry temperature and speed of net bet can be adiusted in order to suitable for different characterisics of vegetable andthe requirement of quality.it can adapt different procass and equip necessary auxiliary equipment in accordance with different characteristics of vegetable.

Application

It can meet to dry diferent vegetables such as, root, halm, leaf, tuberos rot, big granule and produce in batch. Meanwhile it can maintain content ofnutrition,color, etc of vegetable in most extent.The type raw materials are garlic, cushaw, carrot, giantarum, while turnip, yam, bamboo shoot, capsicum, onion, apple, etc.

Principle

The dryer for vegetable dehydration consists of feeder, drying bed, heat exchanger, damp exhaust fan, etc.When operation, air wll be entered into dryer and heated through heat exchanger, Being adapted scienific and reasonable cycle method, the hot air wilpass through raw matenials to be dried on the bed and cary out unitorm heat exchange, under the action of cvcle an. the hot air stream inside aach unit olthe dryer willcary out hot air cycle.Final air with low temperature and high damp wllbe out. The whole dying process with stable and high effect wil befinished.

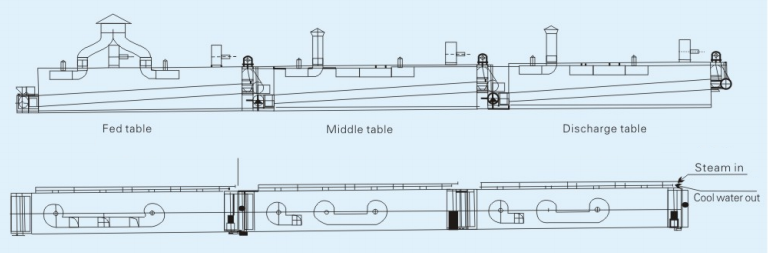

Sketch of structure

fed table

middle table

discharge table

fed table

middle table

discharge table

Note:

1. When make fed fable,.midle table and dischae table with same specifcation menioned above in series for use tcan form the process requrements of roductions line for vegetables dehydration and raise the output obviously and guarantee the quality of products effectively.

2. The height of equipment does not include the height of fan and air duct.