Application

The series chanel sterlization oven is a new style and high effect oven designed and recounted on the basis of absorbing domestic and abroad data andcombining customers experience. lts construction are compact and beauty in shape. ts inner wal and transmission chain all are made of 1Cr18Ni9Tiqualified stainless steel t adapts quartz tube to heat through radiation. Mean while it can also adapt gas to heat accordance with the requirements ofcustomers.lt can sterlize continuously to ampoule botle, cosmetic botle, glassware used for pharmacutical industry, raditional Chinese medicines andso on. its productive field is clean and idy and its productive efficiency is high. Now it is a indispensable equipmentin pharmaceutical factory, traditionaChinese medicine factory, drinking factory, drinking factory and chemical industry concerned with products for daily use.

Principle

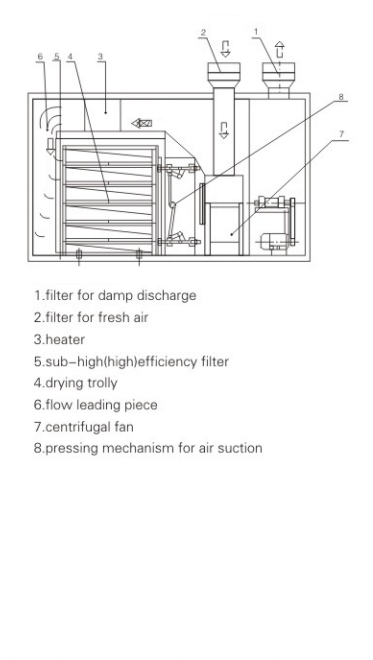

The air steam passes throuah the surface of raw material only in traditional level chamber drier, The disadvantage is that the coelficient of heat transfer is low and the utizaton factor is poor and the dning time so long. ioreover becauseOf the defect of stnucture, it can not be in conformity with the reguirements of “GMP”, in order to overcome the shortcoming, we designed anddeveloped the penetrating ar stream box type drier on the basis of absorbing abroad advanced technology. The pinciple of work is shown in the fiqure listed below :

The fresh ail is sucked through fan and then fterd through pimary, secondany and high eficiency, Therefore the puriication reaches to one hundrecthousand grades. Through steam heat exchanger, the temperature of air is raised to certain temperature. The heated ar is purified through fiter again anthen flows to every layer through left giow divider. it makes the hot ar pas through the raw material to be died evenly. The damp air is sucked from theincined air channel under the drying tray. Pans of damp air are exhausted out off the oven through cntrifuge fan and the other is circled and heated sti.lrthis way the purpose can be realized.

Features

1. Because the hot air of each circle is filtered through sub-high or high efficiency filter, it can avoideffectively that the carried raw material in the air is deteriouated and polluted during the period ofre-circle and re-heating. lt is in conformity with the requirements of ” GMP” fully.

2. Compared with laminar flow type oven, the dry capacity is higher. The thickness of raw materialto be dried is more than three times,

3. The dry area is large and the efficiency is high, Compared with level flow type oven, thecapacity is more than 3-6 times. The cost is lower.

4. lt is suitable for all kinds of raw materials having the shape of granule of block drying.

5. lt is easy in operation and quick in clean and exchange and low in trouble.

6. There are air filters at inlet and outlet. The raw material to be dried can not be polluted and thequality of raw materials to be dried can not be damaged.

7. The heat source may be steam or electric heater.

(ten thousand pieces)