DW Series Single-layer Mesh-Belt Dryer

- Model:DW Series

- Categories:Dryer Series

- Email : contact@he-mu.com

| Parameter | Unit | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-12 |

| Unit number | 4 | 5 | 4 | 5 | 4 | 6 | |

| Belt width | m | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

| Drying section length | m | 8 | 10 | 8 | 10 | 8 | 12 |

| Thickness of the material | mm | 10~80 | |||||

| Temperature | ℃ | 60~130 | |||||

| Steam pressure | Mpa | 0.2~0.8 | |||||

| Steam consumption | kgsteam/kgH₂O | 2.2~2.5 | |||||

| Drying strength | kgH₂O/h | 6~20kg/m³·h | |||||

| Total power of the blower | kW | 3.3 | 4.4 | 6.6 | 8.8 | 12 | 16 |

| Total power of the equipment | kW | 4.05 | 5.15 | 7.35 | 9.55 | 13.1 | 17.1 |

Description

This machine is a continuous penetrating flow drying equipment appliedfor drying pieces strip and particles state materials with good ventilation.The machine is suitable for the materials such as dewatering vegetableherbal medicine of traditional Chinese medicine and others, for which thewater contents are high and high drying temperature is not high. Themachine owns the advantages, of fast drying speed, high evaporationcapacity and good product quality. The de-watered & filtered cake statepaste material should be made into particles or strips before dryingprocess.

Features

1. Amount of air, heating temperature, time of material stay on thebelt and velocity of feeding material can be adjusted in order toobtain the best drying effect.

2. Equipment’s configuration is very flexible.lt can use the netlike belwashing system and cooling raw material system.

3. Hot air can be circularly applied, the energy is greatly saved.

4. Unique air dividing device, it makes hot air distribute uniformly; this canguarantee products” quality.

5. Heating source can be selected from steam, conducting heat oil.electricity, coal furnace and oil burner.

Application

De-watering vegetable,particle feed, gourmet powder, shreddedcoconut stuffing, organic plastic, compound rubber, acral fibre, medicineproduct, medicine material, small wooden product, plastic product, agingand solidification for the electronic component and device.

Principle

The materials are uniformly distributed on the mesh-belt by the materialfeeder. The mesh-belt generally adopts 12-60 mesh stainless steelmesh and it is drawn by a transmission device and move inside the dryerThe dryer is composed of several sections. For each section, the hot airis circulated separately. Part of exhausted gas is exhausted by a speciamoisture exhaust blower. The waste gas is controlled by an adjustmentvalve. The hot air passes through the mesh-belt covered with, materiafrom the top to the bottom or from the bottom to the top and this willcomplete the heat and mass transfer process. This process will bringwater away. The mesh-belt moves slowly, running speed can be freelyadjusted according to the material property. The final products after thedrying process will fall into the material collector continuously. The topand low circulation units can be freely equipped according to the user’srequirements. The number of section might be selected according to theproduction demands.

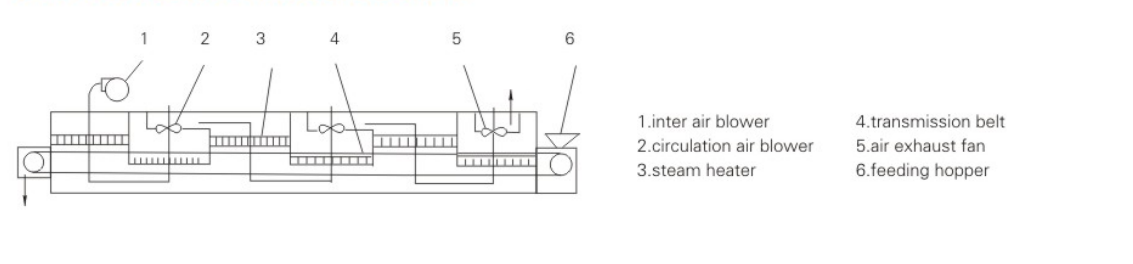

Schematic of stracture